Milling Machine Series

CNC operations

120

Advantech-LNC Technology Co., Ltd.

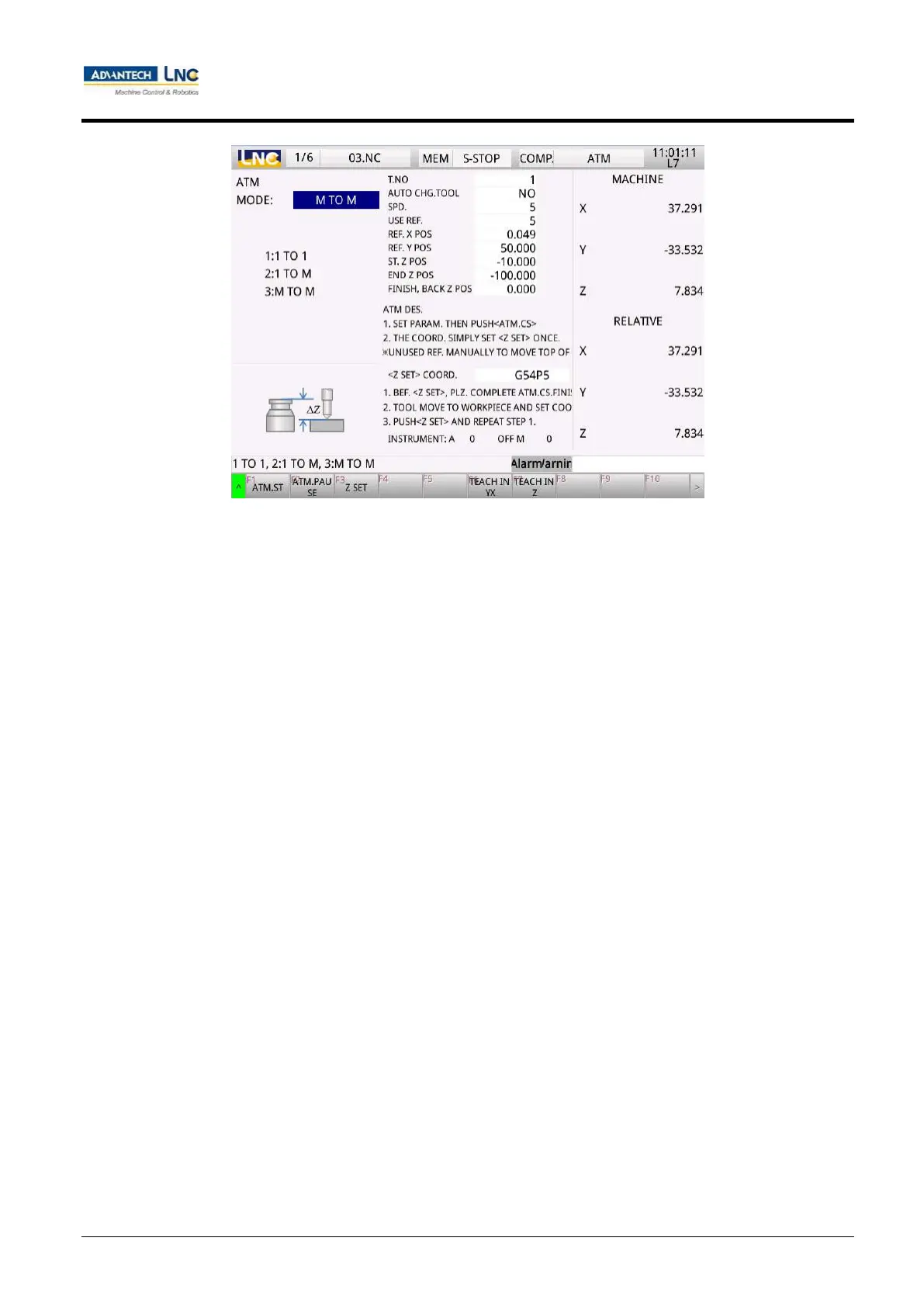

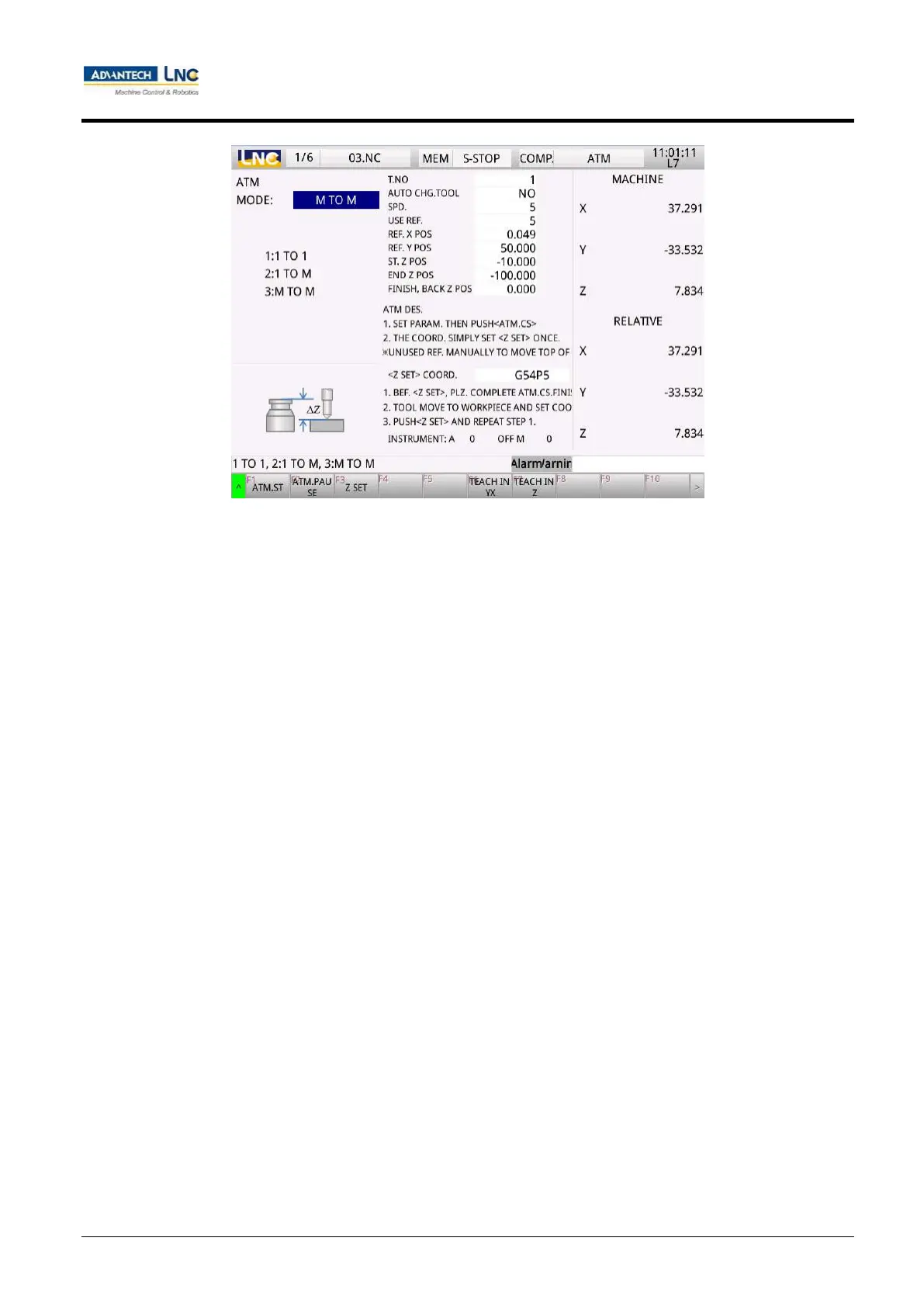

Move the cursor to the tool alignment mode field, enter the value 3 in the input area and press the <Input> key

to set the mode as single tool/multiple workpieces.

Set "Tool number": Move the cursor to the "Tool number" field, enter a numerical value (from 1 to 99) in the

input area and press the <Input> key.

Set "Is automatic tool change required": Move the cursor to the "Is automatic tool change required" field, enter a

numerical value (from 0 to 1) in the input field and press the <Input> key.

Set "Measurement speed": Move the cursor to "Measurement speed", enter a numerical value in the input field

and then press the <Input> key.

Set "Whether to use a reference point": Move the cursor to the "Whether to use a reference point" field, enter a

numerical value (from 0 to 1) in the input field and press the <Input> key. If a reference point is to be used, it

should be switched to hand wheel mode (MPG), and the tool should be moved to the position above the tool

alignment instrument. After confirming that the tool tip is right above the tool alignment instrument, the cursor

should be moved to the "Tool alignment instrument's X coordinate reference point" field, press the 【XY axis

guide】 key to set up both "Tool alignment instrument's X coordinate reference point" and "Tool alignment

instrument's Y coordinate reference point". If a reference point is not used, please move the tool to the position

above the tool alignment instrument manually.

Replace the current tool with the longest tool, use the hand wheel to move the tool (and stop when the tool tip

is at a certain distance away from the tool alignment instrument) while making sure the tool tip is not in contact

with the tool alignment instrument. Move the cursor to the "Tool alignment starting point Z" and press the 【Z

axis guide】 key for guided input.

Replace the current tool with the shortest tool, use the hand wheel to move the tool such that the tool tip is

deviated from the tool alignment instrument by a small distance (not directly above the tool alignment

instrument), move the tool tip to a location at around 2 mm (not too much) lower than the normal position of

the tool alignment instrument and stop right here. The cursor should be moved to the "Z axis lowest machine

Loading...

Loading...