NNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

Fltness Menu

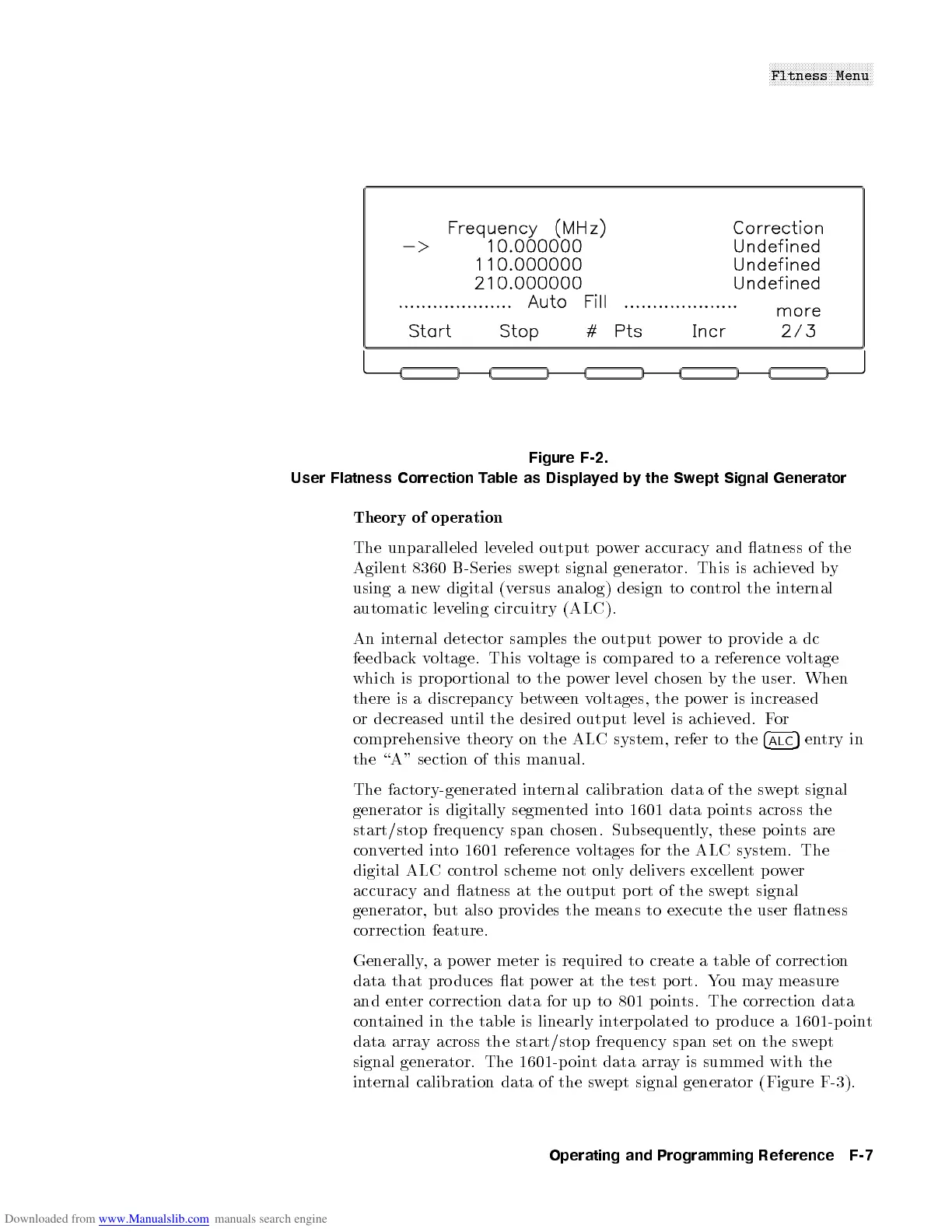

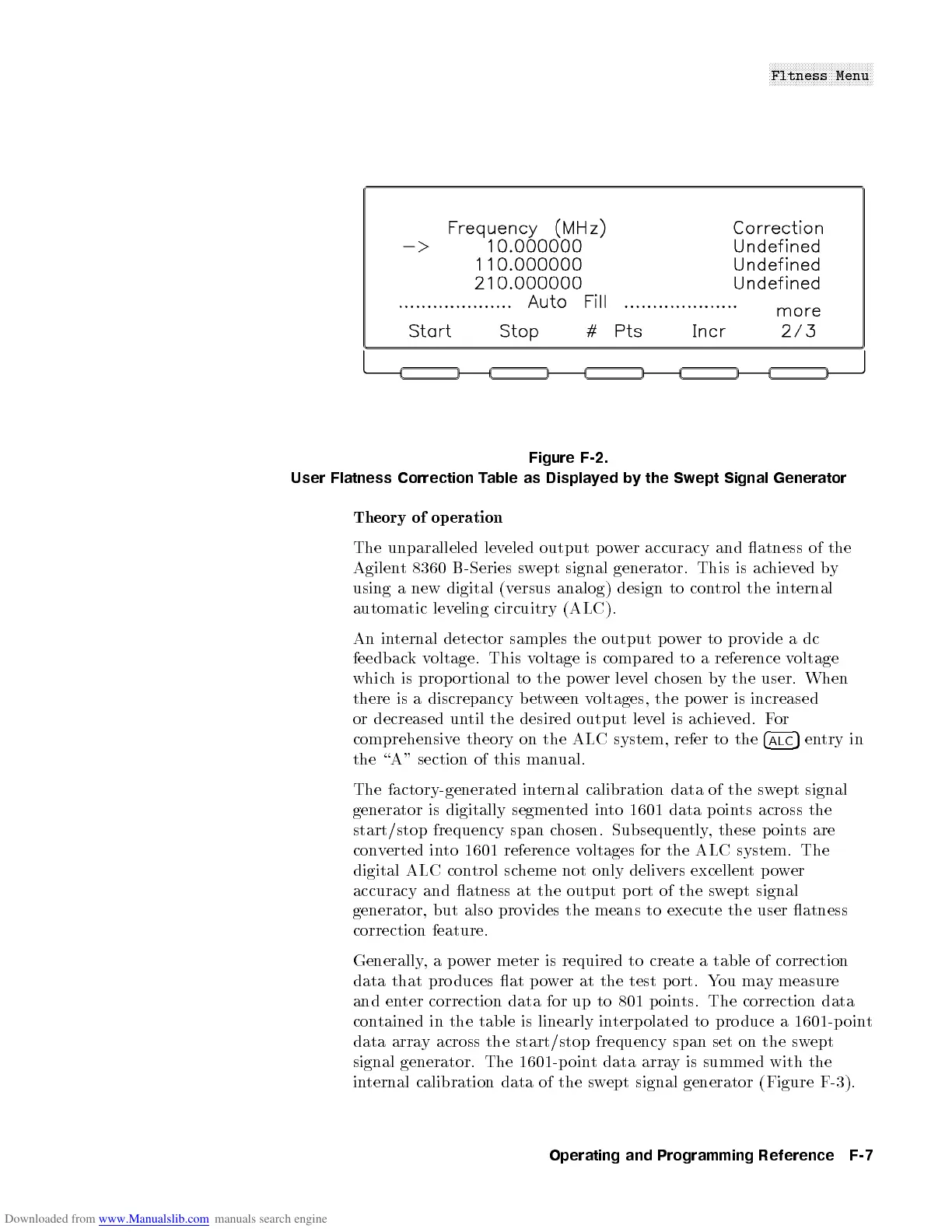

Figure F-2.

User Flatness Correction Table as Displayed by the Swept Signal Generator

Theory of op eration

The unparalleled leveled output power accuracy and atness of the

Agilent 8360 B-Series swept signal generator. This is achieved by

using a new digital (versus analog) design to control the internal

automatic leveling circuitry (ALC).

An internal detector samples the output power to provide a dc

feedbackvoltage. This voltage is compared to a reference voltage

which is prop ortional to the p o

wer level chosen by the user. When

there is a discrepancy b etween voltages, the p ower is increased

or decreased until the desired output level is achieved. For

comprehensive theory on the ALC system, refer to the

4

ALC

5

entry in

the \A" section of this manual.

The factory-generated internal calibration data of the swept signal

generator is digitally segmented into 1601 data points across the

start/stop frequency span chosen. Subsequently, these points are

converted into 1601 reference voltages for the ALC system. The

digital ALC control scheme not only delivers excellentpower

accuracy and atness at the output p ort of the sw

ept signal

generator, but also provides the means to execute the user atness

correction feature.

Generally,apower meter is required to create a table of correction

data that pro duces at power at the test p ort. You may measure

and enter correction data for up to 801 p oints. The correction data

contained in the table is linearly interpolated to pro duce a 1601-p oint

data array across the start/stop frequency span set on the sw

ept

signal generator. The 1601-p oint data array is summed with the

internal calibration data of the swept signal generator (Figure F-3).

Operating and Programming Reference F-7

Loading...

Loading...