1 About Maintaining the GC

Tools and Materials Required for Maintenance

Maintaining Your GC 11

Tools and Materials Required for Maintenance

Table 1 lists the tools needed for most GC maintenance procedures. The specific tools

required to perform a maintenance procedure are listed in step 1 of each procedure.

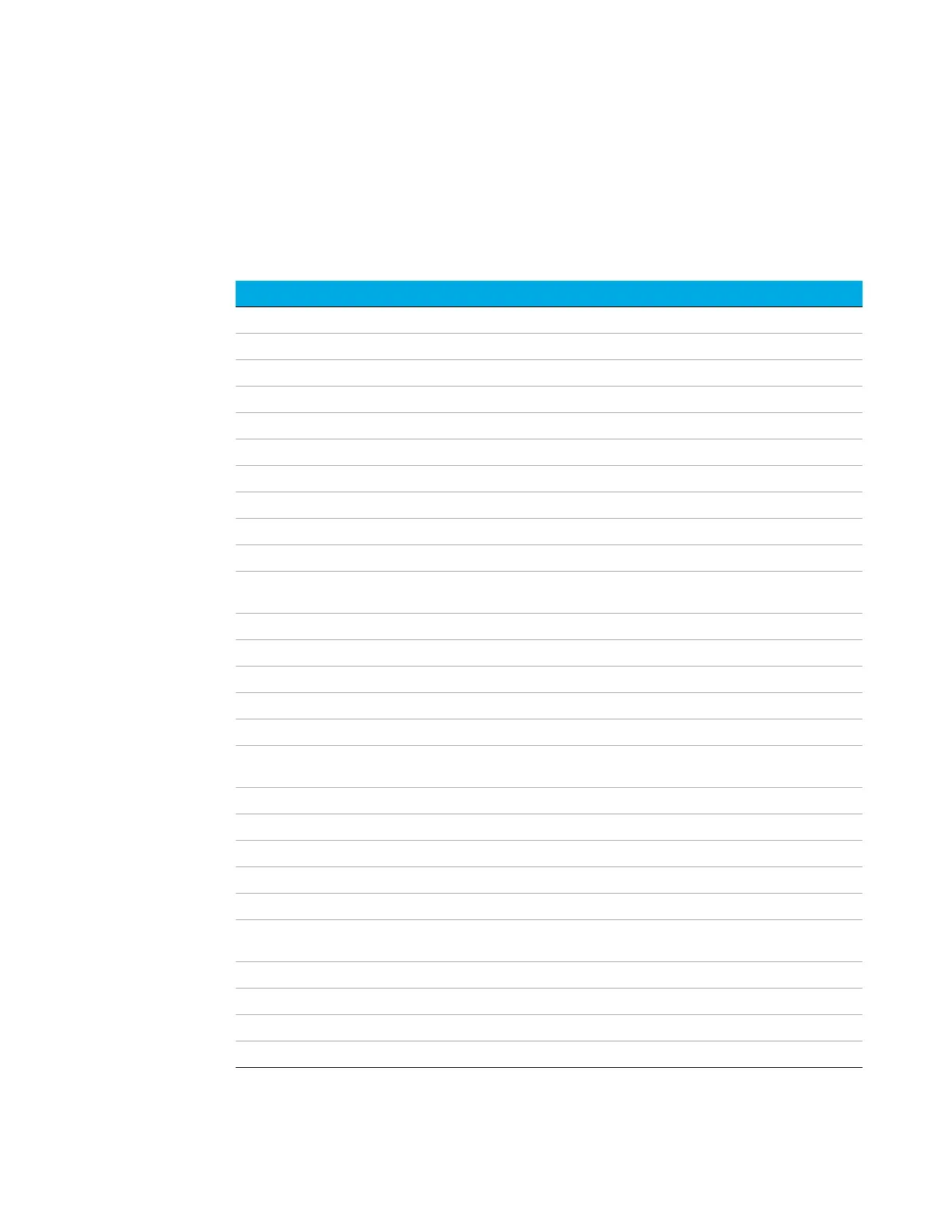

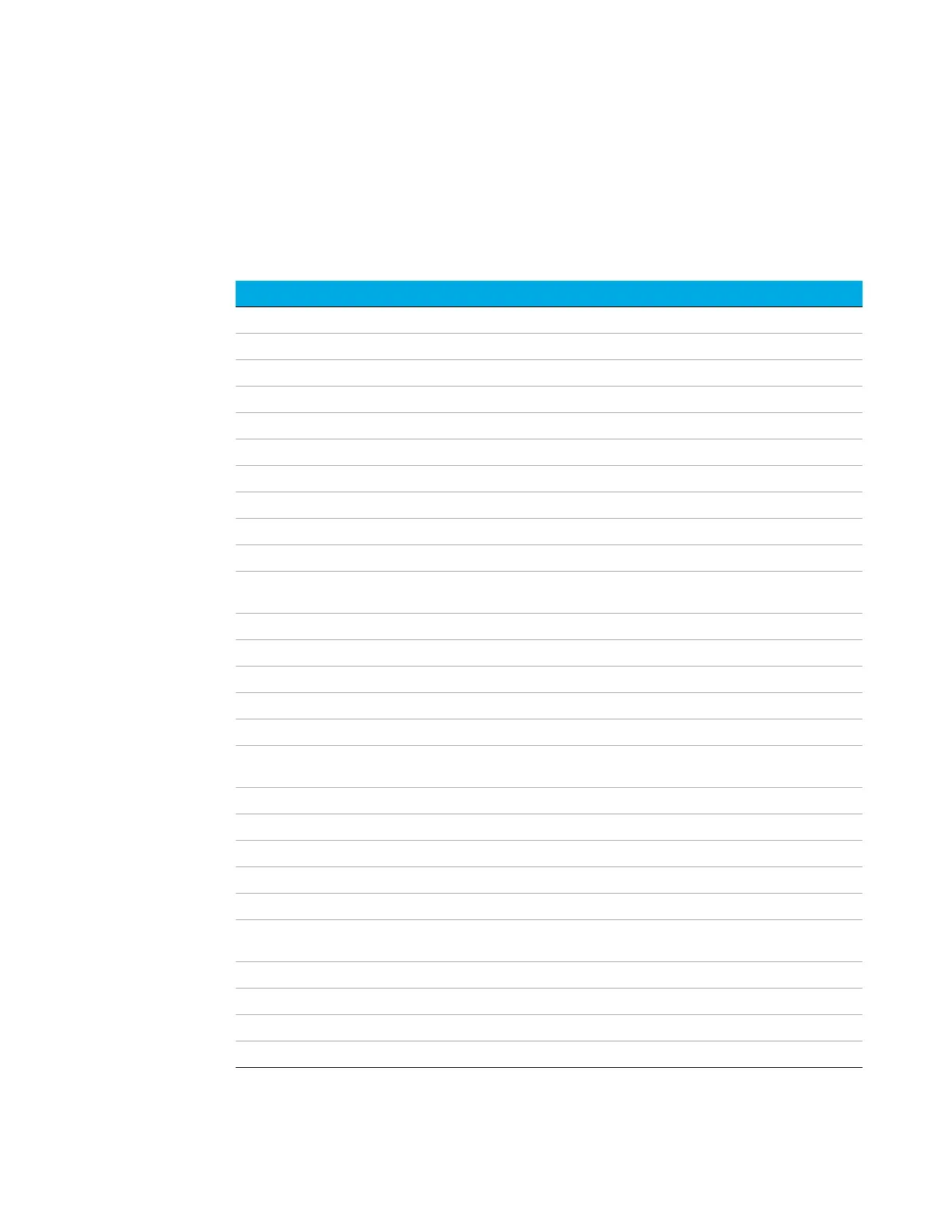

Table 1 Tools and materials for GC maintenance

Common tools Part number

Wrench, angled, septum nut 19251-00100

Wrench, open-end, 1/4-inch and 5/16-inch 8710-0510

*

Wrench, open-end, 9/16-inch and 7/16-inch 8710-0803

Wrench, capillary inlet G3452-20512*

Flathead screwdriver

Column cutter, wafer, 4/pk 5181-8836*

Driver, nut, 1/4-inch 8710-1561*

T-20 Torx key or screwdriver 8710-1807

T-10 Torx key or screwdriver 8710-2140

3-mm hex key wrench 8710-2411

Electronic flow meter(s) or bubble meter(s) capable of calibrated measurements at 1, 10, and

100 mL/min flow ranges

Electronic leak detector

Magnifying loupe, 20X 430-1020

Metric ruler

Bench vise (for setting Swagelok fittings)

Razor or sharp knife

Tweezers, or

thin needle-nose pliers

8710-0007

8710-0004

Needle-nose pliers

ESD wrist strap (for installing new components) 9300-1408

Gloves, heat-resistant (for handling hot parts)

Wooden cotton swab (for removing FID filters)

Tools and materials for cleaning procedures

Cleaning brushes—The FID cleaning kit contains appropriate brushes for cleaning detectors and

inlets

9301-0985

Cleaning brushes—For cleaning split/splitless inlet split vent fitting, FID and collectors 8710-1346

Jet cleaning wire (.010-inch)

Clean, lint-free cloth (to protect contamination-sensitive detector parts)

Small ultrasonic cleaning bath with aqueous detergent (for cleaning detector and inlet parts)

Loading...

Loading...