8 Maintaining the COC Inlet

To Change a Septum on the COC Inlet

128 Maintaining Your GC

To Change a Septum on the COC Inlet

1 Gather the following:

• Replacement septum, see “Consumables and Parts for the Cool On-Column Inlet” on

page 120.

• Tweezers

• A thin wire (0.2-inch diameter) for removing septum from inlet

• Lint-free gloves

2 Launch the GC maintenance wizard: Maintenance > Inlets, select the inlet, then select

Perform Maintenance > Replace Septum > Start Maintenance. The wizard will guide you

through the maintenance steps described below.

Be careful! The oven and/or inlet may be hot enough to cause burns. If either is hot, wear

heat-resistant gloves to protect your hands.

Wear clean, lint-free gloves to prevent contamination of parts with dirt and skin oils.

3 Replace the septum.

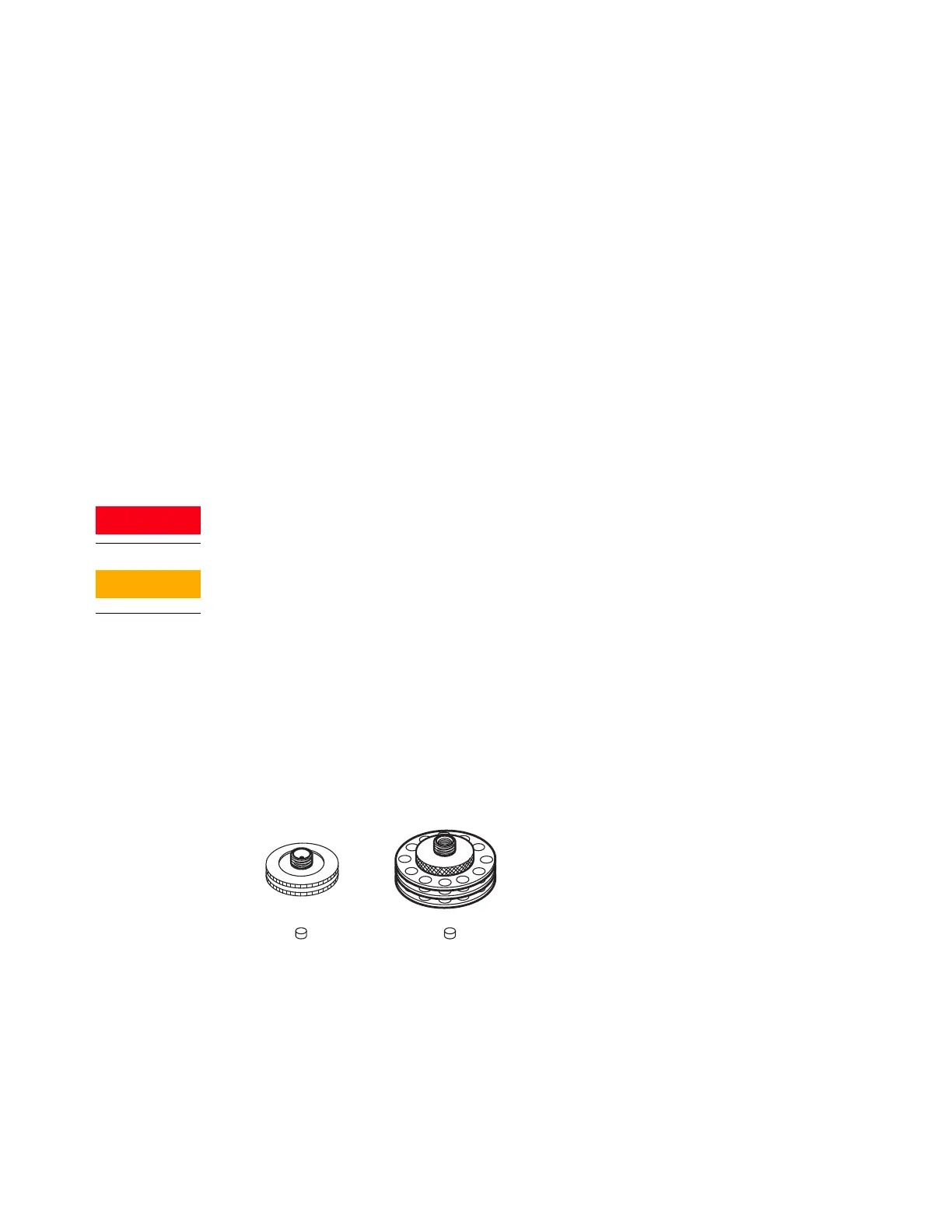

• If you are using a septum nut, grasp the knurling and unscrew. Remove the old septum

with tweezers.

• Use tweezers to install a new septum. Push the septum into the septum nut until

properly seated. Firmly tighten the nut.

• If you are using a cooling tower, grasp the three rings and unscrew. The spring and

duckbill septum may pop out of the inlet when you remove the cooling tower. Be careful

not to lose them. If they do not pop out, use a thin wire to remove them from the inlet.

Insert the replacement duckbill septum into the spring and place in the inlet. Reattach

the cooling tower assembly, then finger-tighten.

For 250/320-µm

automated injections

For 530-µm automated

injections

Loading...

Loading...