6 Maintaining the Purged Packed Inlet

To Install a Packed Glass Column

Maintaining Your GC 91

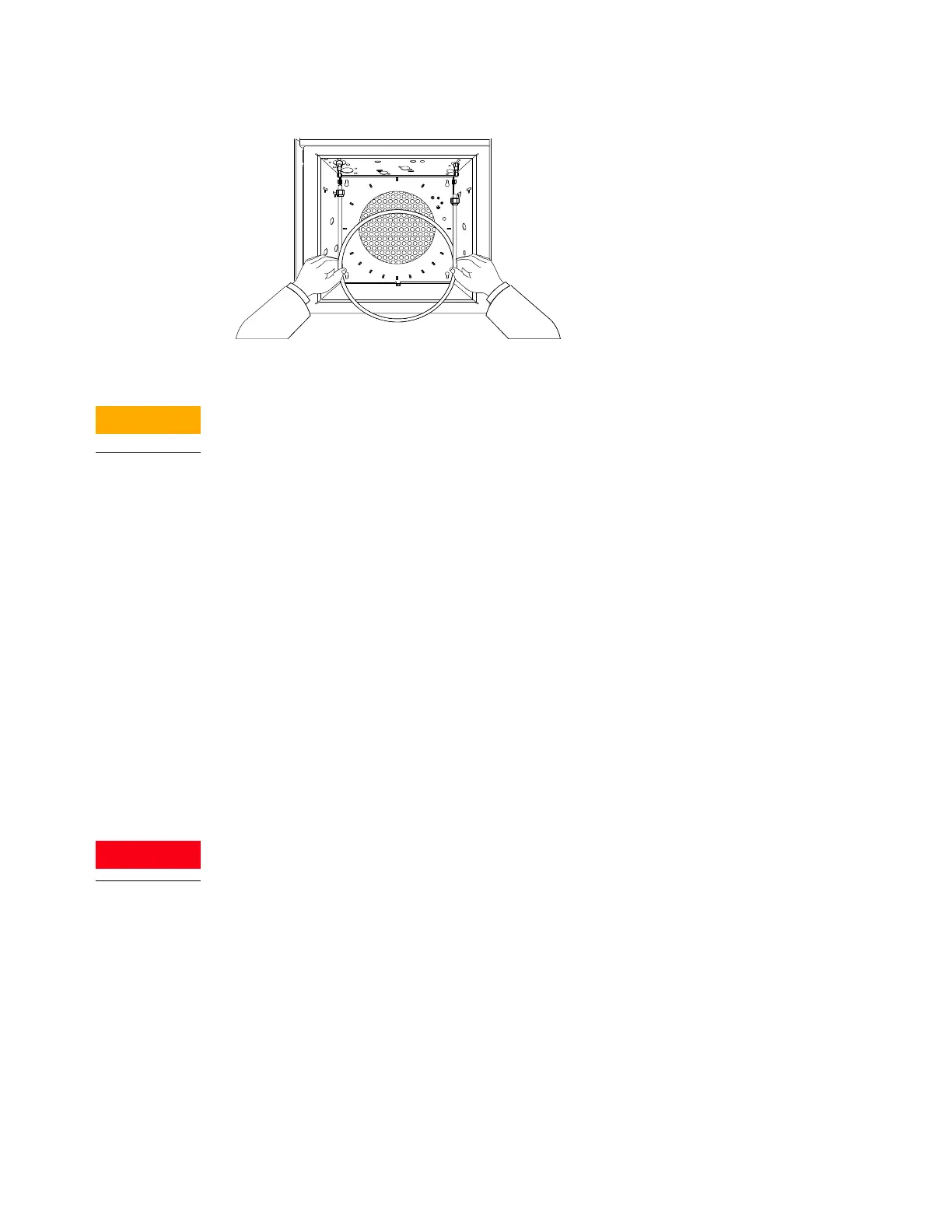

8 Withdraw the column 1 to 2 mm from both the inlet and detector. Finger-tighten both

column nuts.

Overtightening the column nut or forcing it to bottom in either the inlet or detector may

shatter the column.

9 Tighten both column nuts 1/4 turn with a wrench.

10 The GC maintenance wizard will perform checks at the appropriate times, including Leak &

Restriction tests, and will automatically reset the maintenance counters.

11 Select Finished, then select OK to exit the GC maintenance wizard.

12 Configure the new packed column (make sure either column length or diameter is zero).

13 Establish a flow of carrier gas and purge as recommended by the packing manufacturer.

Generally:

• 20 to 30 mL/min for 2-mm id glass or 1/8-inch od metal columns

• 50 to 60 mL/min for 4-mm id glass or 1/4-inch od metal columns

14 Restore the analytical method.

• For FPD+, immediately turn off the flame.

• For NPD, immediately turn off the bead.

15 After the GC becomes ready, wait 10 minutes then ignite the detector flame or adjust

offset on the NPD bead.

Be careful! The oven, inlet, and/or detector may be hot enough to cause burns. If the oven,

inlet, or detector is hot, wear heat-resistant gloves to protect your hands.

16 Allow the oven, inlet, and detector to equilibrate at operating temperature, then retighten

the fittings.

17 Perform the inlet Leak & Restriction test and reset the maintenance counters.

Loading...

Loading...