32 Rockwell Automation Publication 20B-IN026C-EN-P - October 2015

Chapter 2 Basic Component Removal Procedures

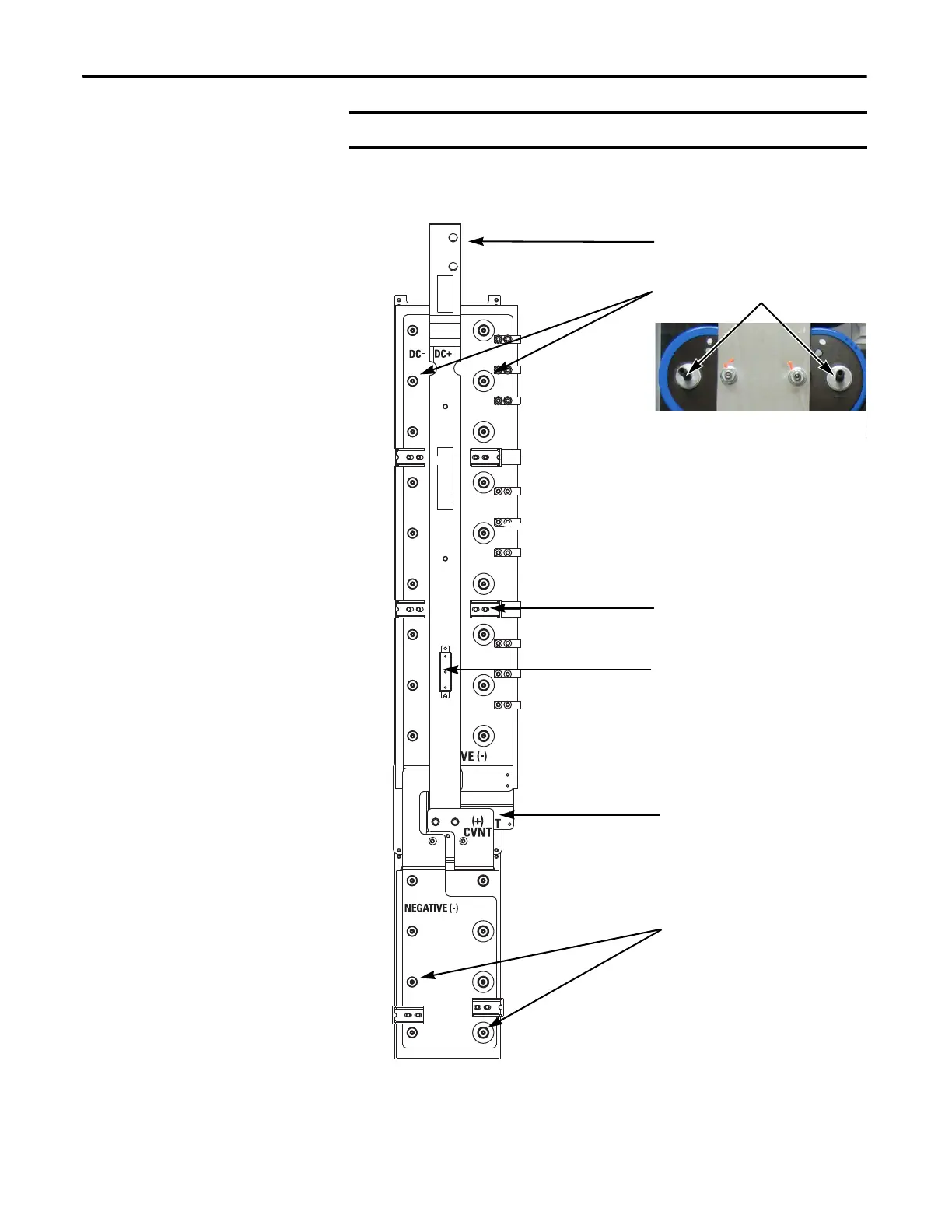

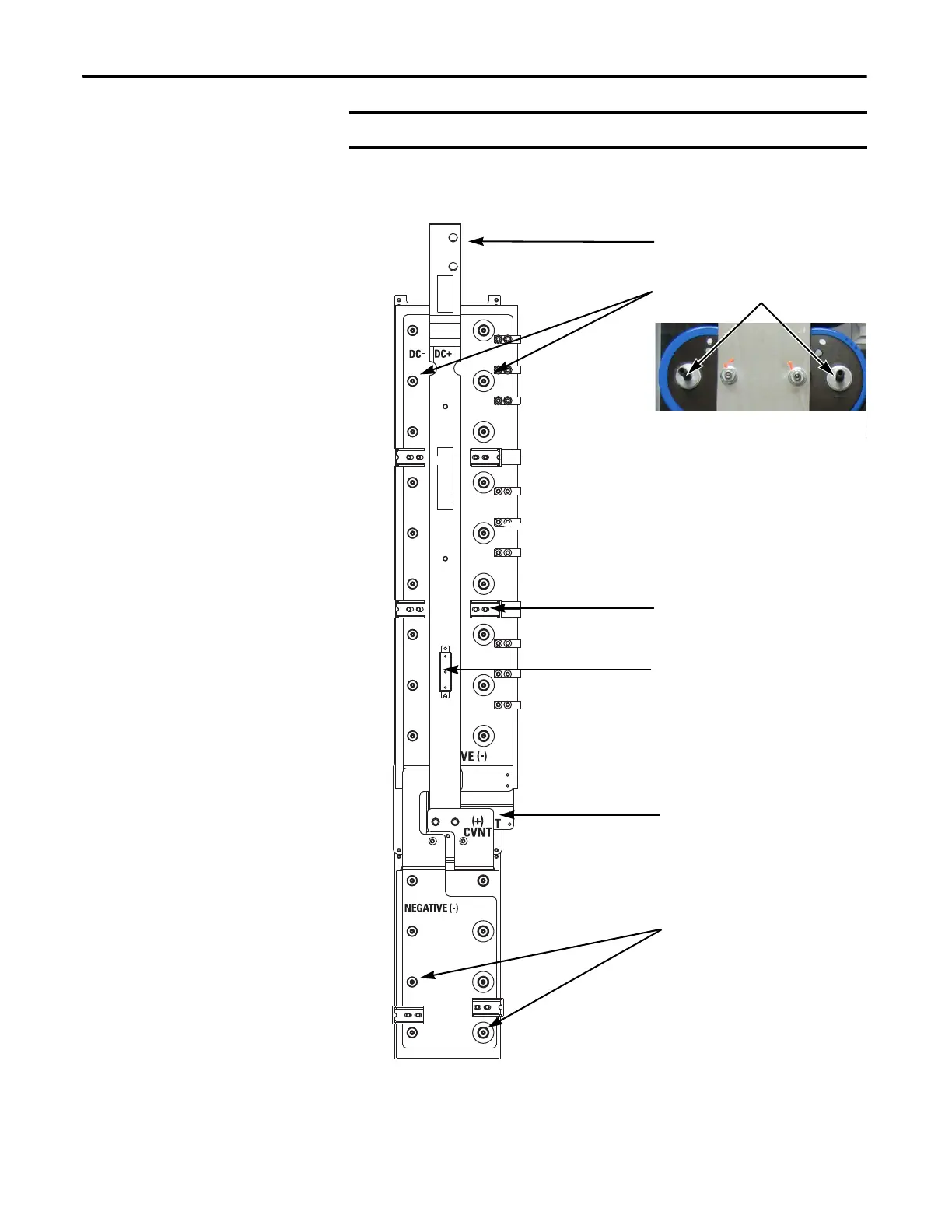

15. Remove the Transitional Busbar assembly.

Set screws may come out with the nuts. Save all nuts and set screws.

Upper Capbus Support Nuts (18)

attached to Set Screws

Side Standoffs and Brackets (6)

DC Choke Output Cables

Note: Photo shows set screws in

Capacitors; these set screws may come out with

the Transitional Busbar assembly nuts when they

are removed.

Lower Capbus Support Nuts (8)

attached to Set Screws

Upper and Lower Capbus Support

Connecting Brackets

Balancing Resistor

(Old Style Resistor Shown)

Loading...

Loading...