10–7

Troubleshooting

Publication

1747-6.2

The Following

Error Exists

Probable Cause Recommended Action

Initial CPU Factory

Power-up

Condition

1. Refer to chapter 8 and follow the start-up procedures.

2. Clear processor memory to get rid of the flashing CPU

FAULT LED.

CPU Major

Fault

Hardware/Software

Major Fault

Detected

Erratic repetitive

power cycling can

cause a processor

major hardware

fault.

1. Monitor Status File Word S:6 for major error code.

2. Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or the Instruction Set

Reference Manual for error codes and additional

troubleshooting information.

3. Remove hardware/software condition causing fault.

4. Clear Status File S:1/13 major error bits, if set.

5. Clear Status File S:5 minor error bits, if set.

6. Clear Status File S:6 major error code (optional).

7. Attempt a processor Run mode entry.

If unsuccessful, repeat recommended action steps above.

The Following

Error Exists

Probable Cause Recommended Action

System does

not operate per

ladder logic.

User Forced I/O

Disabling

Operation

1. Monitor program file online and identify forced I/O.

2. Disable appropriate forces and test system conditions

again.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual.

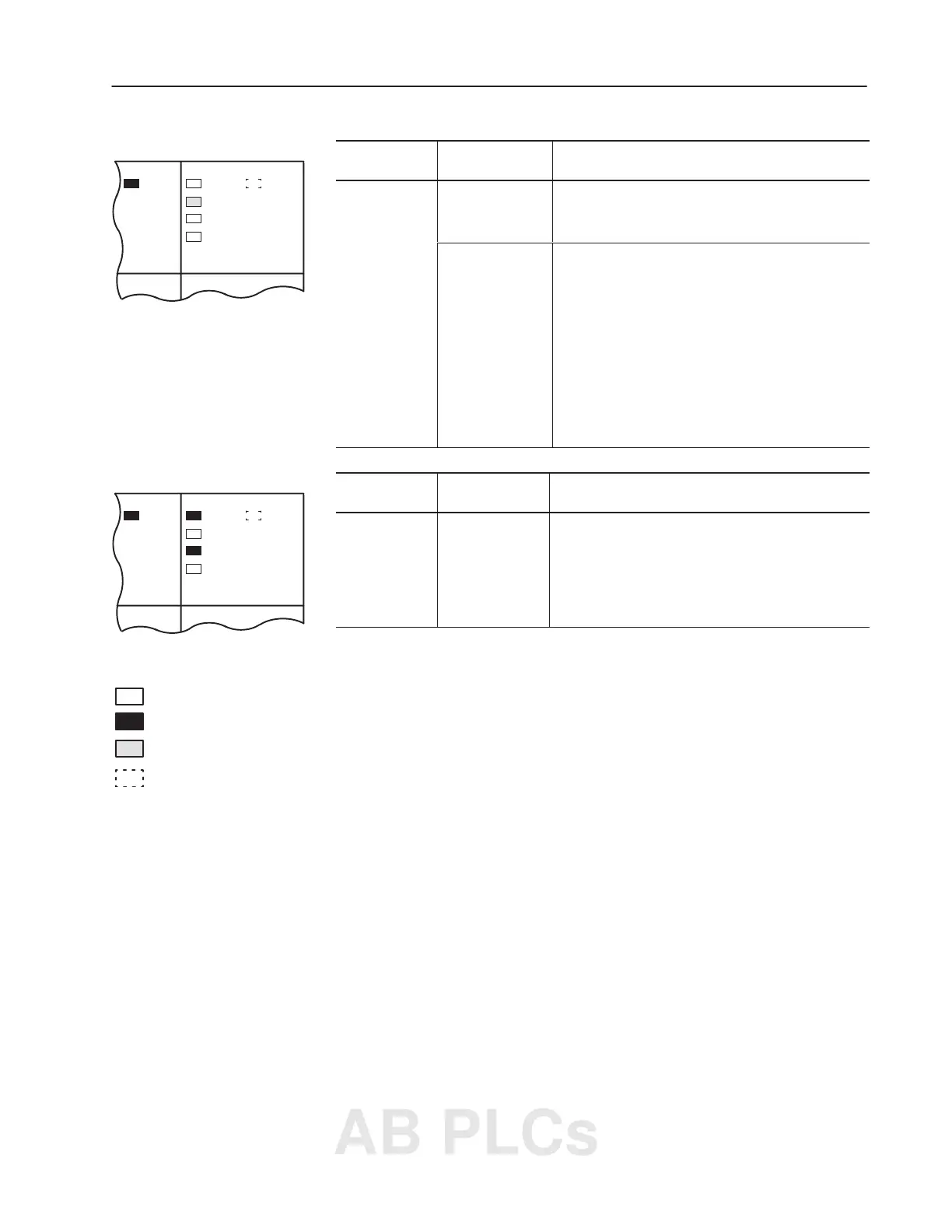

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Indicates the LED is FLASHING.

Status of LED does not matter.

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

COMM

If the LEDs indicate:

➀

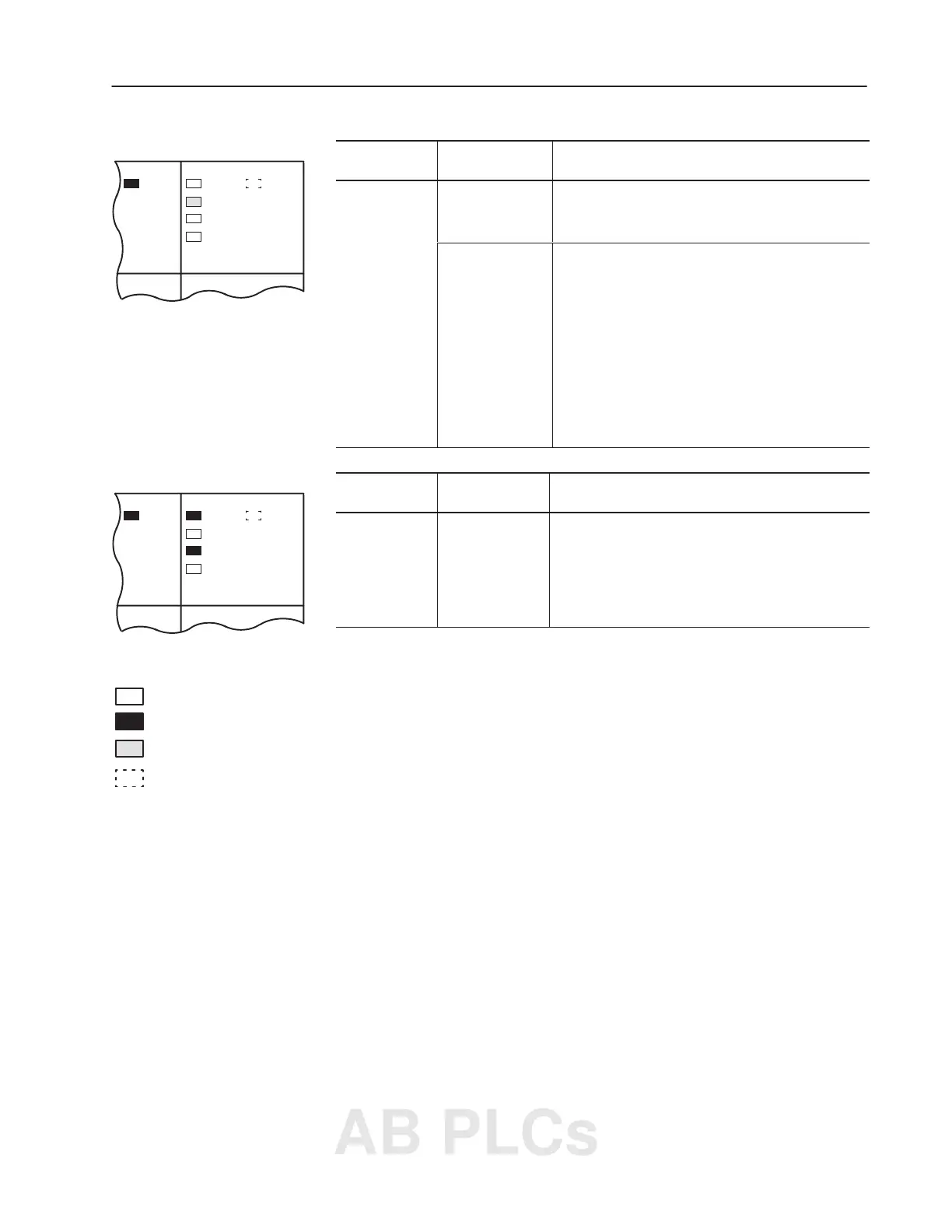

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

COMM

If the LEDs indicate:

➀

AB PLCs

Loading...

Loading...