Rockwell Automation Publication 1560F-UM001A-EN-P - June 2019 53

Installation Chapter 2

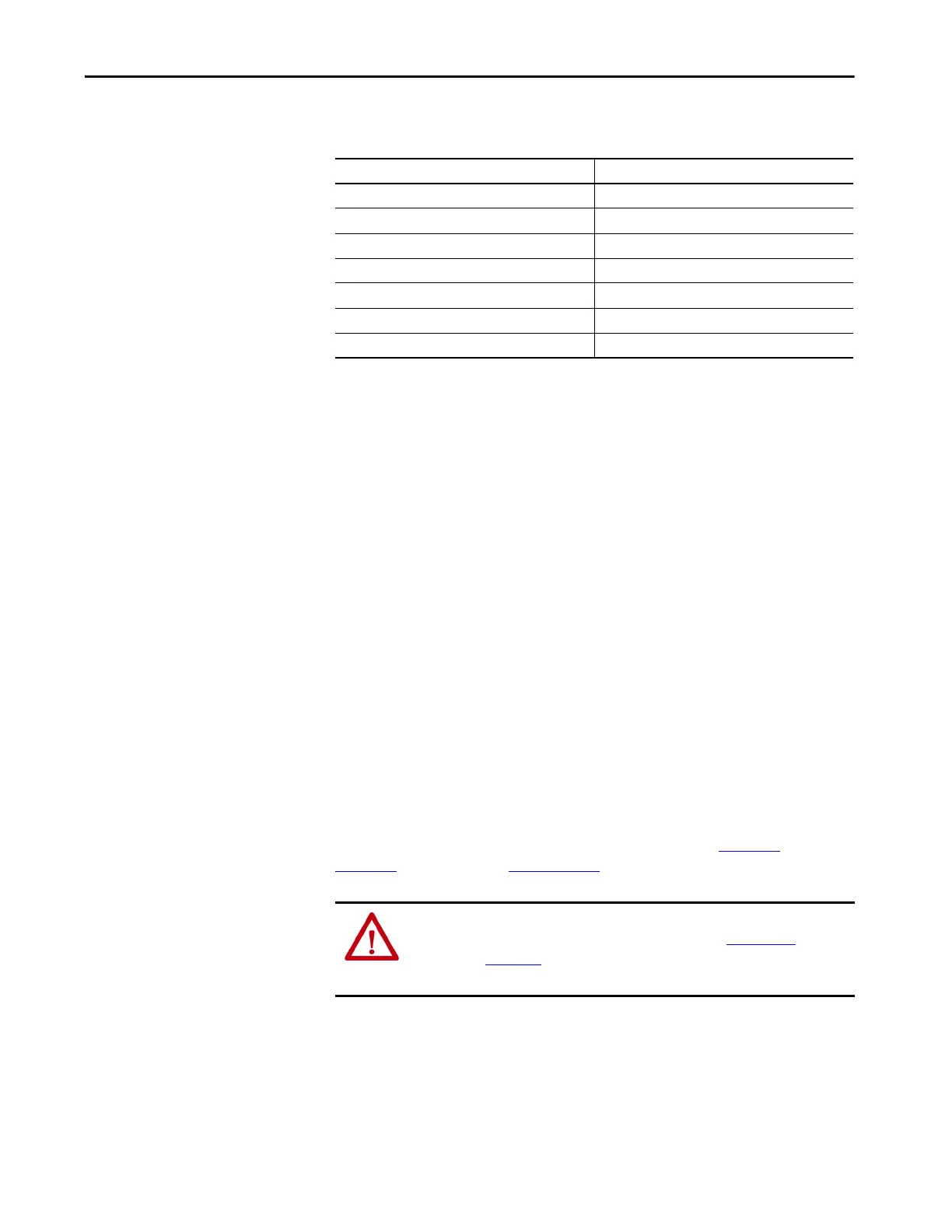

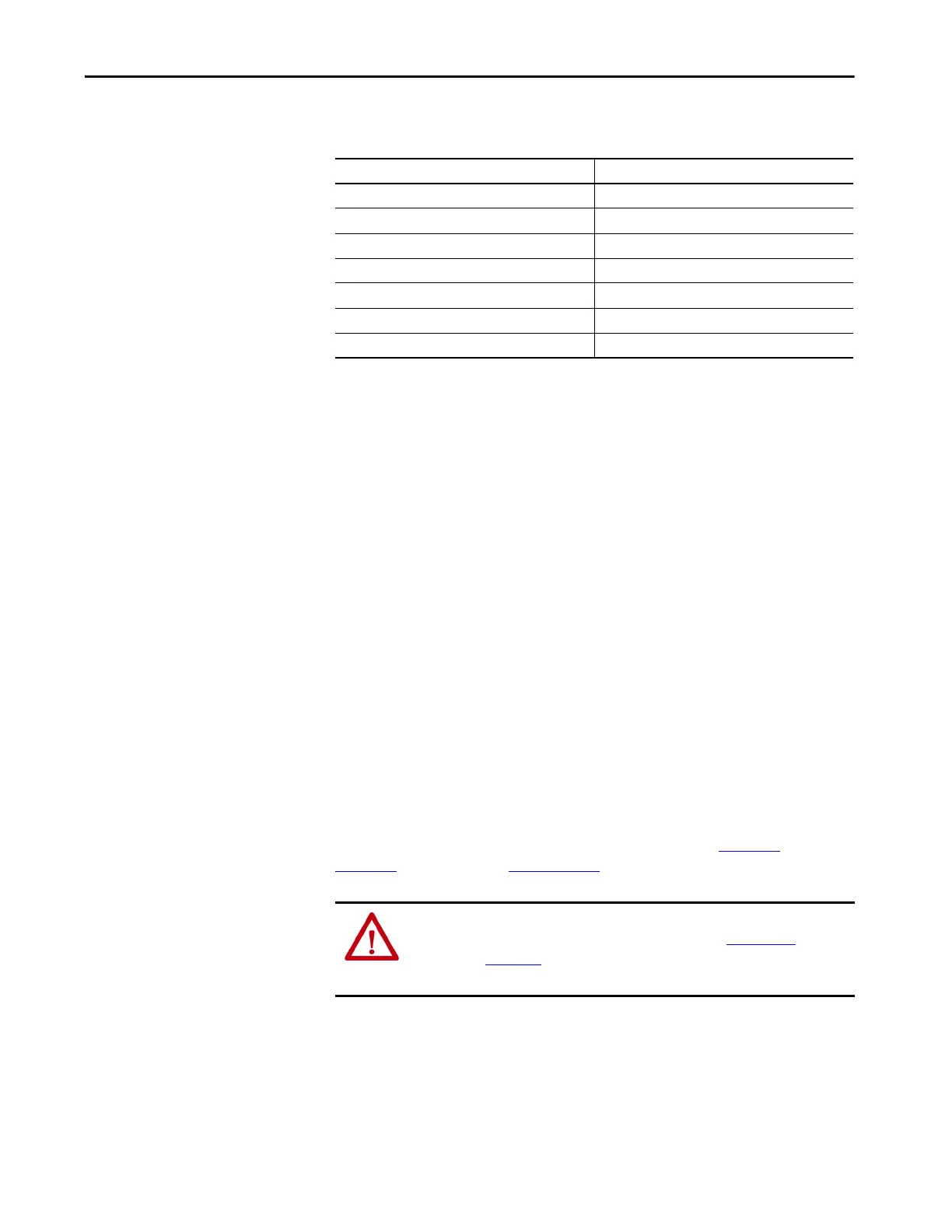

Recommended Torque

Values

When reinstalling components or when reassembling the cabinet, tighten the

following bolt sizes to the specified torque values:

Power Connections

The controller requires a three-phase supply and an equipment grounding

conductor to earth ground. A neutral conductor of the three-phase supply is not

necessary and is usually not routed to the controller. Three-phase wiring will

connect the controller to the motor.

Bulletin 1562F

The Bulletin 1562F unit is available in two main configurations:

1. A modified two-high cabinet (180/360 A, 2400…4160V)

2. A combination of a one-high full voltage non-reversing (FVNR) cabinet

and a 1560F unit (600 A, 2400…4160V, and 180/360/600 A,

5500…6900V)

To make power connections for a two-high cabinet, refer to Figure 28

to

Figure 30

, and publication 1500-UM055 (Chapter 2).

To make power connections for a one-high FVNR cabinet and a 1560F unit,

proceed as follows:

• Make line connections within the one-high cabinet

• Make load connections at the primary load current transformer terminals

Hardware Recommended Torque

1/4 in. (M6) 8 N•m (6 lb•ft)

5/16 in. (M8) 15 N•m (11 lb•ft)

3/8 in. (M10) 27 N•m (20 lb•ft)

1/2 in. (M12) 65 N•m (48 lb•ft)

Control Wire Terminals 2.5…4.0 N•m (2.0…3.3 lb•in)

CLGD Power Assembly Terminals 5.6 N•m (50 lb•in)

SMC-50 Control Module Terminals 0.6 N•m (5 lb•in)

TIP For 3/8 in. hardware in the “T”-slots of aluminum heatsinks, the recommended

torque is 22 N•m (16 lb•ft). Do not overtorque these connections as the slots

will be damaged and the connection will be compromised.

ATTENTION: Bulletin 1562F units provided with an arc resistant enclosure must

be installed in accordance with instructions in publication 1500-UM055

. See

publication MV-QS050

for level floor surface requirements. Failure to do so may

result in damage to equipment or personal injury.

Loading...

Loading...