98 Rockwell Automation Publication 1560F-UM001A-EN-P - June 2019

Chapter 4 Programming

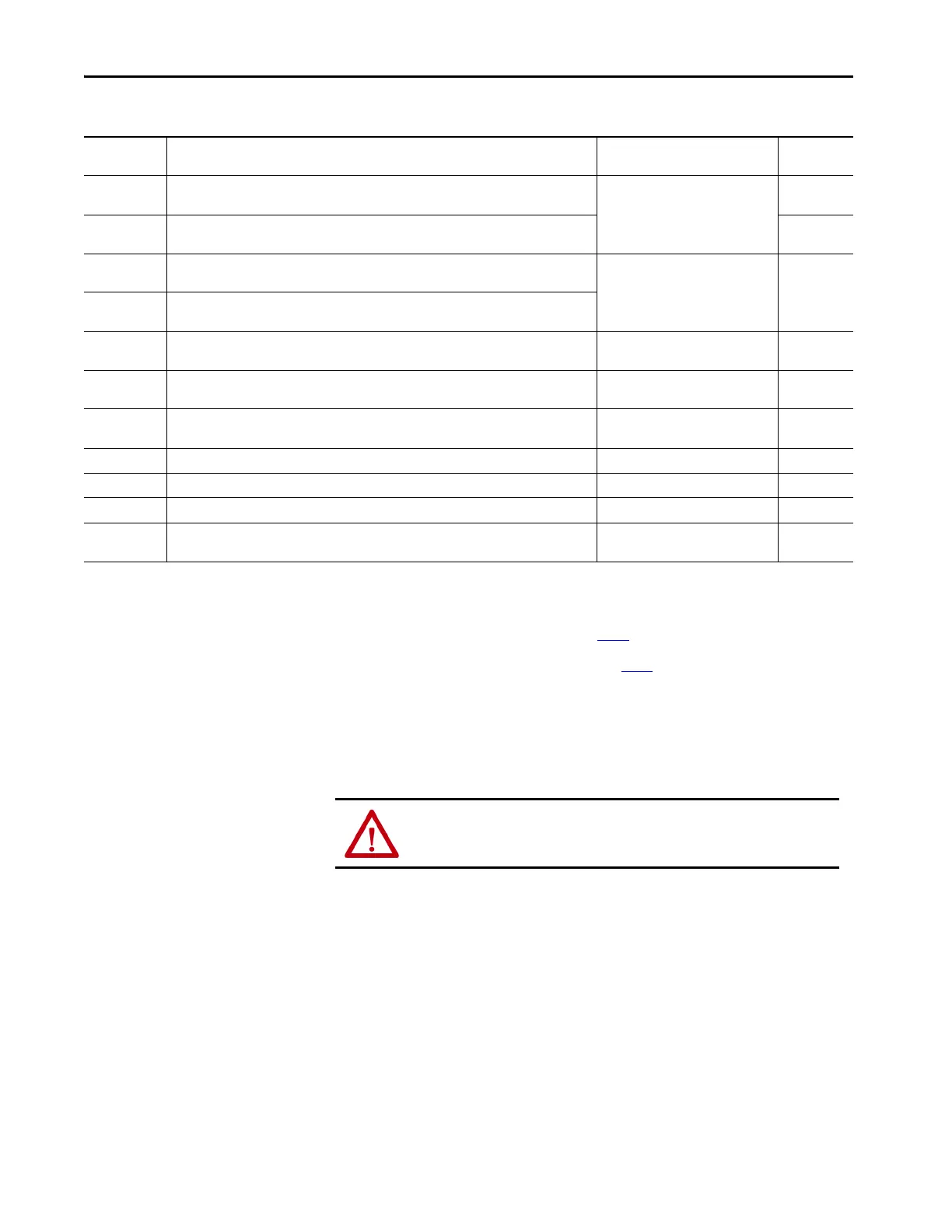

Input 1 Programs the desired operation of the Control Module to a change in status of Input #1 wired to

control terminal #11 (24V DC).

Disable, Start, Coast, Stop Option, Start/

Coast, Start/Stop, Dual Ramp, OL

Select, Fault, Fault NC, Clear Fault,

Emerg Run

Start/Coast

Input 2 Programs the desired operation of the Control Module to a change in status of Input #2 wired to

control terminal #10 (24V DC).

Disable

Aux 1 Config Aux 1 Config Programs the control function of the Auxiliary Output Contact #1, wired across control

terminal #4 and #5.

(4)

Normal, UTS, Fault, Alarm, Ext Bypass,

Ext Brake, Aux Control

(7)

, Network 1,

Network 2, Network 3, Network 4,

Fan Control

Normal

Aux 2 Config Programs the control function of the Auxiliary Output Contact #2, wired across control terminal #6

and #7.

(4)

Overload Class Required for motor protection. Lets you select the time-to-trip for the built-in Motor Overload.

This selection is based on the type of motor being used and the application it is being applied to.

5…30 10

Service Factor Required for motor protection. This value is taken directly from the nameplate and used by the

controller to determine the ultimate Overload Trip Current.

0.01...1.99 1.15

Motor FLC Required for motor protection. This programmed value is taken directly from the motor

nameplate.

1.0...2200.0 A 1.0 A

Starting Torque NOT used for a Soft Start. 0...300% RMT 100% RMT

Max Torque NOT used for a Soft Start. 0...300% RMT 250% RMT

Rated Torque NOT used for a Soft Start. 0...100,000 N•m 10 N•m

Rated Speed NOT used for a Soft Start. 750, 900, 1000, 1200, 1500, 1800,

3500, 3600 rpm

1800 rpm

(1) In the AUTO Detect [default] selection, the controller automatically checks the motor configuration.

(2) Enter a value to limit the current but not low enough to inhibit the start cycle.

(3) The stopping mode does not need to match the starting mode (for example, a Soft Start can have a stop mode programmed for [Coast], or Linear Stop—there is no Current Limit Stop or Torque Stop

mode).

(4) Relay Operational Options (for example, ON and OFF delay, etc.) are provided in the File: Setup, Group: I/O selection sequence. See Ta ble 1 1

.

(5) Kickstart is available when using Soft Start. A Kickstart Level and Time must be configured if this mode is used. Access these parameters via the Starting Setup Group. The Starting Setup Group can be

accessed with the HIM from the Port <00> DEV PARAM folder under the File-Group, File: Setup, Group: Starting selection sequence (see Table 11

). Setting either parameter to zero disables Kickstart.

(6) You can also program a start delay time to delay starting for a period of time after the initiation of the START command. The Start Delay parameter can be accessed from the Group Starting selection

as noted.

(7) Any auxiliary output configured for Aux Control using the AuxX Config parameter is under control of its associated bit from the Aux Control, Parameter 180. See Parameter 180 information for bit

assignments.

NOTE: This function enables forcing an output, ON or OFF.

Table 12 - Soft Start Parameter Group (Continued)

Parameter

Name

Description

Options

Default

Value

ATTENTION: For Overload Protection, it is critical that you enter the data into

the SMC-50 control module as it appears on the motor nameplate.

Loading...

Loading...