74

6.5.2.1 Cleaning the steam generator

If the water is hard (above about 6 dH) there is a risk of limescale

deposits forming on the elements of the steam generator. The

elements should be checked and cleaned once or twice a year.

• Remove the cover below the ball valve. Empty the steam

generator by opening the ball valve.

• Remove the hose and the check valve.

• Remove the entire steam generator from the pipe system of

the machine. Before the steam generator can be opened, the

insulation must be removed and then the clamping ring.

• Remove any limescale deposits on the elements with

limescale remover or mechanically (take care, since the

elements are welded to the end panel).

• Before re-assembling the steam generator, replace the O-ring

EHWZHHQWKHKDOYHVRIWKHWDQN7KHQ¿WWKHFODPSLQJULQJ

Tighten carefully to avoid damaging the O-ring.

• 5H¿WWKHLQVXODWLRQDQGVHFXUHLWZLWKDGKHVLYHWDSH

• Fit the cover to the ball valve, making sure that the ball valve

is closed.

• Install the steam generator on the pipe system. The gasket

between the steam generator and the pipe system of the

machine must be replaced.

• 5H¿WWKHKRVHDQGQRQUHWXUQYDOYH

• If there is leakage from the check valve, dismantle the check

valve and clean the sealing surfaces in the valve body and

on the O-ring. On re-assembly, the locking screw must be

screwed in until it bottoms in the valve body.

If the problem with the deposits is severe, we recommend

LQFUHDVLQJWKHGRVDJHDPRXQWVHH³&KHFNLQJWKHGRVDJH

amount”).

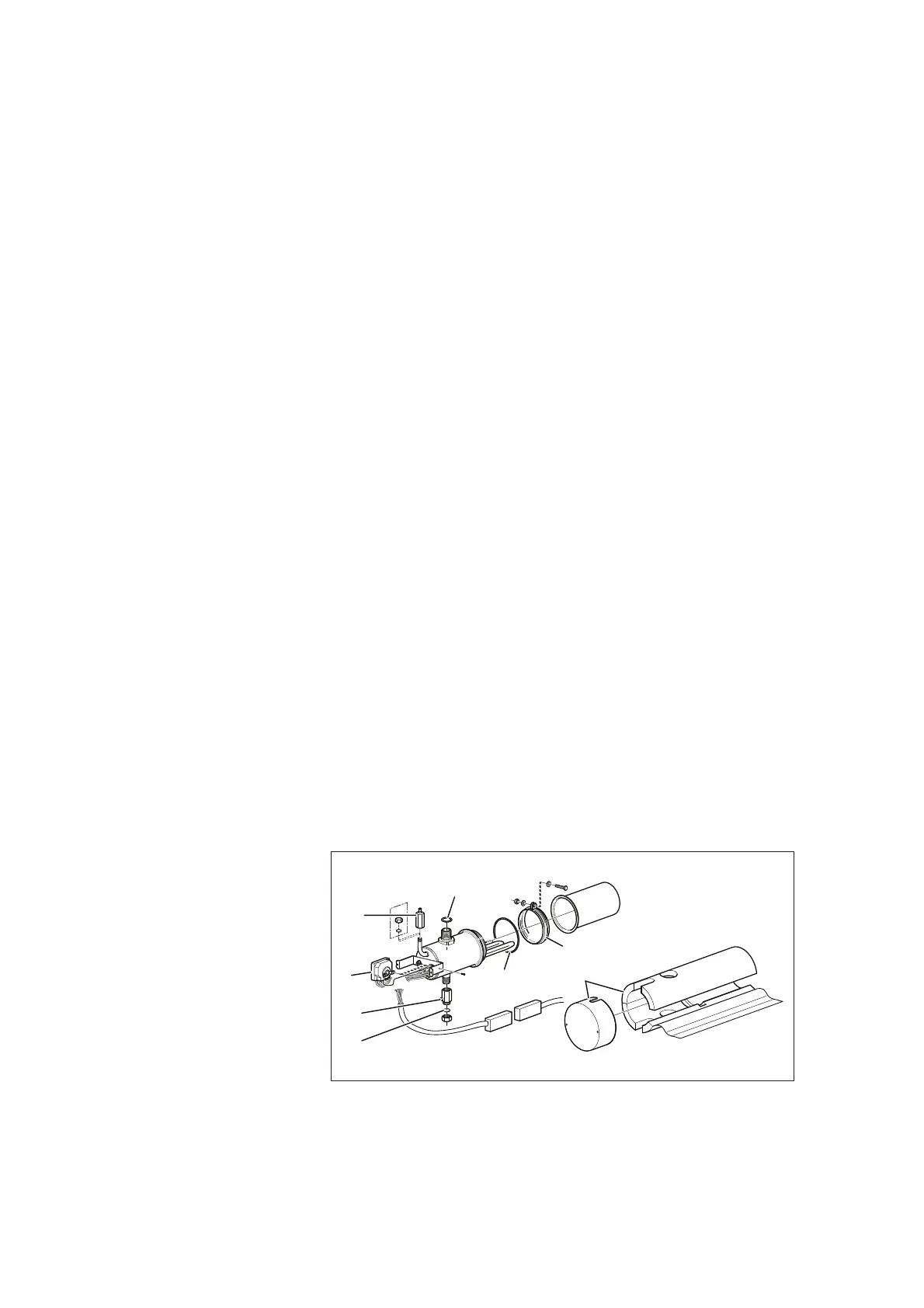

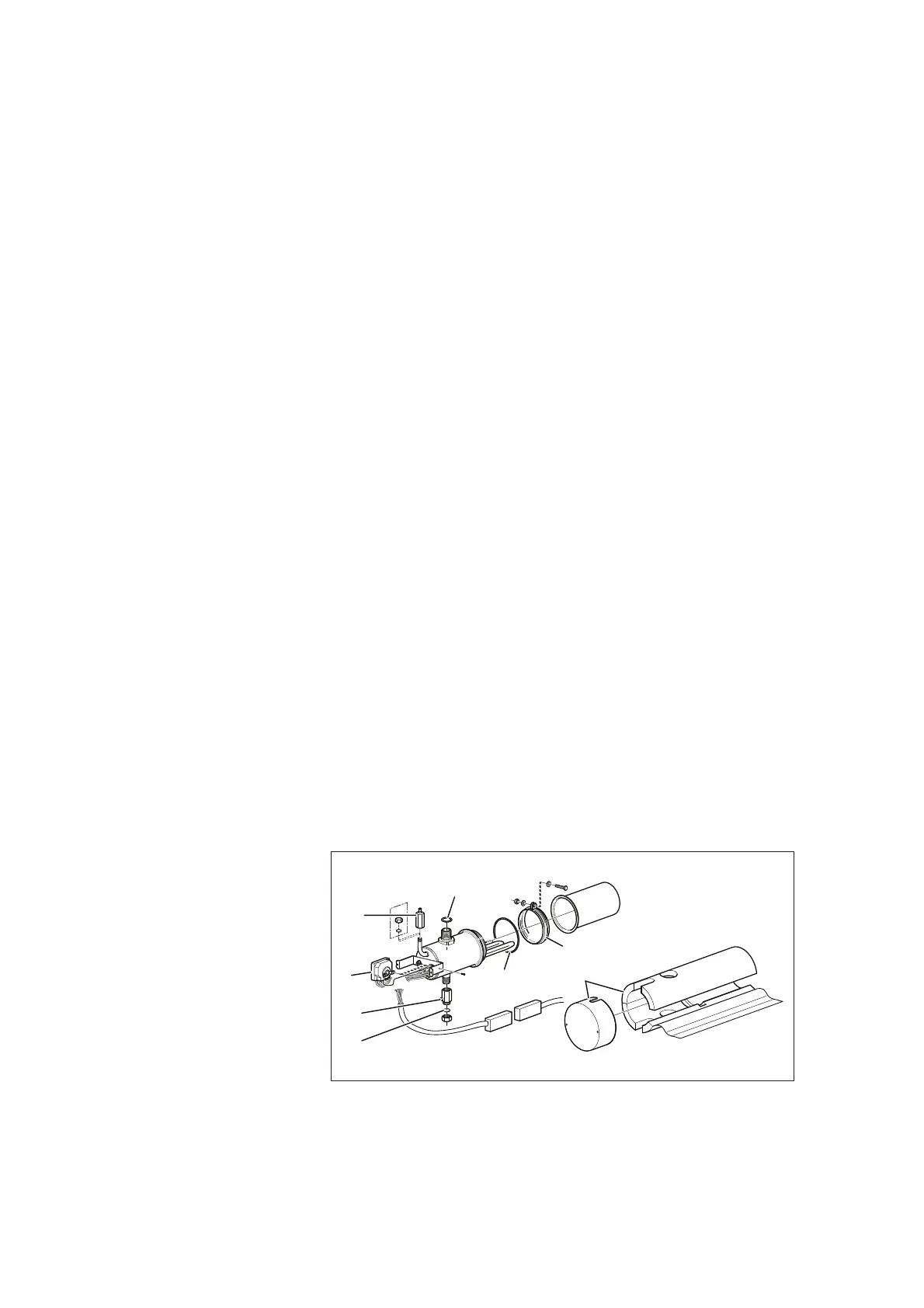

1

2

7

6

8

3

4

5

001440

Figure 8. Components in the steam generator

1. Check valve 5. Cover

2. Sealing 6. O-ring

3. Overheat protection 7. Clamping ring

4. Ball valve 8. Insulation

Loading...

Loading...