Model 8640B TM 9-4935-601-14-7&P

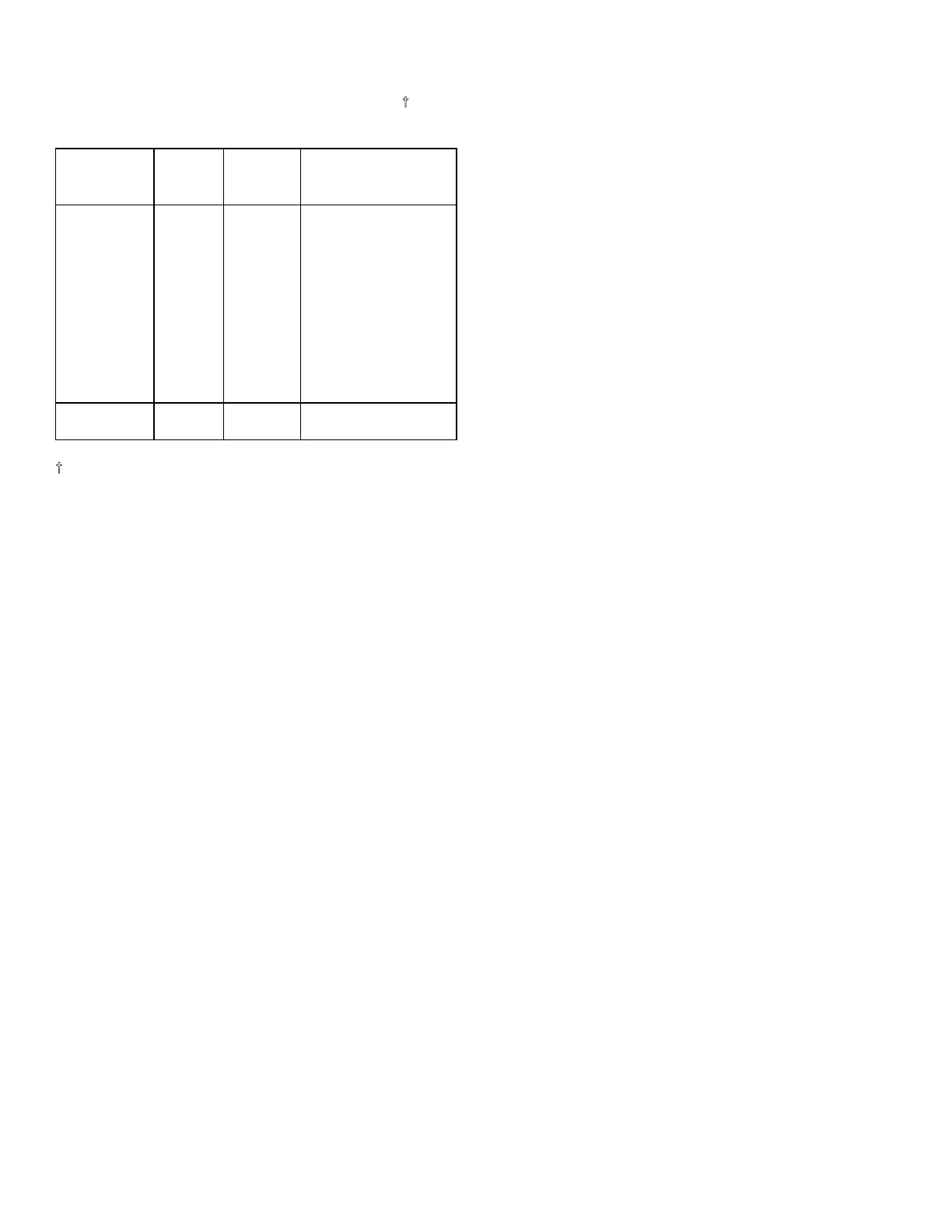

Table 5-1. Factory Selected Components

(2 of 2)

Service Range of

Component Sheet Values Basis of Selection

A11R28 9A 215 to See paragraph 5-27.

(Option 001) 316 ohms Select for less than

specified distortion

with distortion

analyzer connected

to front panel

output jack. (Dis-

tortion should not

be so low that

amplitude stability

is poor at 20 Hz.)

A26A3C3, 12 0.22 pF See paragraph 5-21.

C4, C5, C6

See backdating, Tables 7-1 and 7-2.

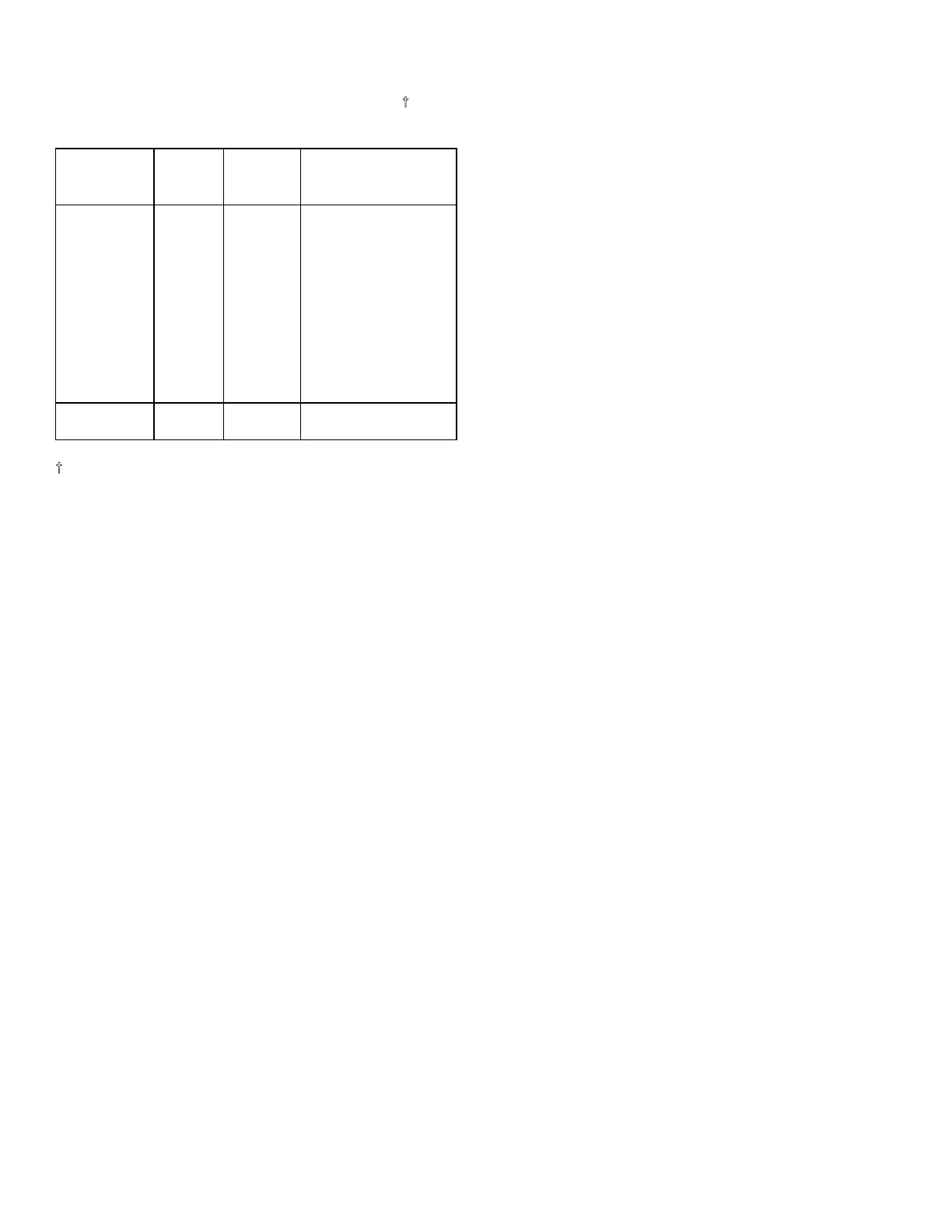

5-22. POST-REPAIR TEST AND ADJUSTMENTS

5-23. The adjustments in this section should be

performed when the troubleshooting information in

Section VIII indicates that an adjustable circuit is not

operating correctly. Perform the adjustments after

repairing or replacing the circuit. The required

adjustments are specified in Table 5-2. Allow the

instrument to warmup one hour before making any

adjustment.

5-24. After making the adjustments, perform the

performance tests (found in Section IV) specified in the

table. In general, if any casting was opened (or any RF

connectors removed) during a repair, the Output

Leakage Test should be performed. Performance tests

should also be made for any assembly that had a

component changed, even if the changed component

was not defective. The power supplies should be

checked whenever an assembly has been repaired.

NOTE

Table 5-2 can also be used for

troubleshooting. If the generator failed

one or more performance tests, cross-

referencing to the associated assembly

or circuitry will often indicate the source

of the failure.

5-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...