Model 8640B TM 9-4935-601-14-7&P

SECTION III

OPERATION

3-1. INTRODUCTION

3-2. This section describes the functions of the controls

and indicators of the Model 8640B Signal Generator. It

explains how to set the frequency, amplitude, and

modulation controls, and covers such operator

maintenance as fuse and indicator lamp replacement

and fan filter cleaning.

3-3. PANEL FEATURES

3-4. Front panel controls, indicators, and connectors are

shown and described in Figure 3-2. Rear panel controls

and connectors are shown and described in Figure 3-3.

3-5. OPERATOR'S CHECKS

3-6. Use the operator's checks in Figure 3-4 to verify

proper operation of the Signal Generator's main

functions.

3-7. OPERATING INSTRUCTIONS

3-8. Figures 3-5 and 3-6 explain how to set the

frequency, amplitude, and modulation controls. Figure

3-5 also explains how to use the frequency counter and

phase lock controls.

3-9. OPERATOR'S MAINTENANCE

3-10. Fuse. The main ac line fuse is located on the

rear panel next to the line power cable jack. To remove

the fuse, first remove the line power cable from its jack.

Slide the fuse compartment cover to the left, then pull

the handle marked FUSE PULL and remove the fuse.

CAUTION

Be sure to select the correct fuse

rating for the selected line voltage

(see LINE VOLTAGE SELECTION in

Section II); fuse ratings are listed on

the fuse compartment.

3-11. Fan. The cooling fan's filter is located on the rear

panel. To service the fulter use a No. 2 Pozidriv

screwdriver (HP 8710-0900) to remove the four screws

that hold the filter to the rear panel. Then clean it, using

a solution of warm water and soap, or replace it, using

the part number listed in the table of replaceable parts in

Section VI.

3-12. The fan motor has factory lubricated, sealed

bearings and requires no periodic maintenance.

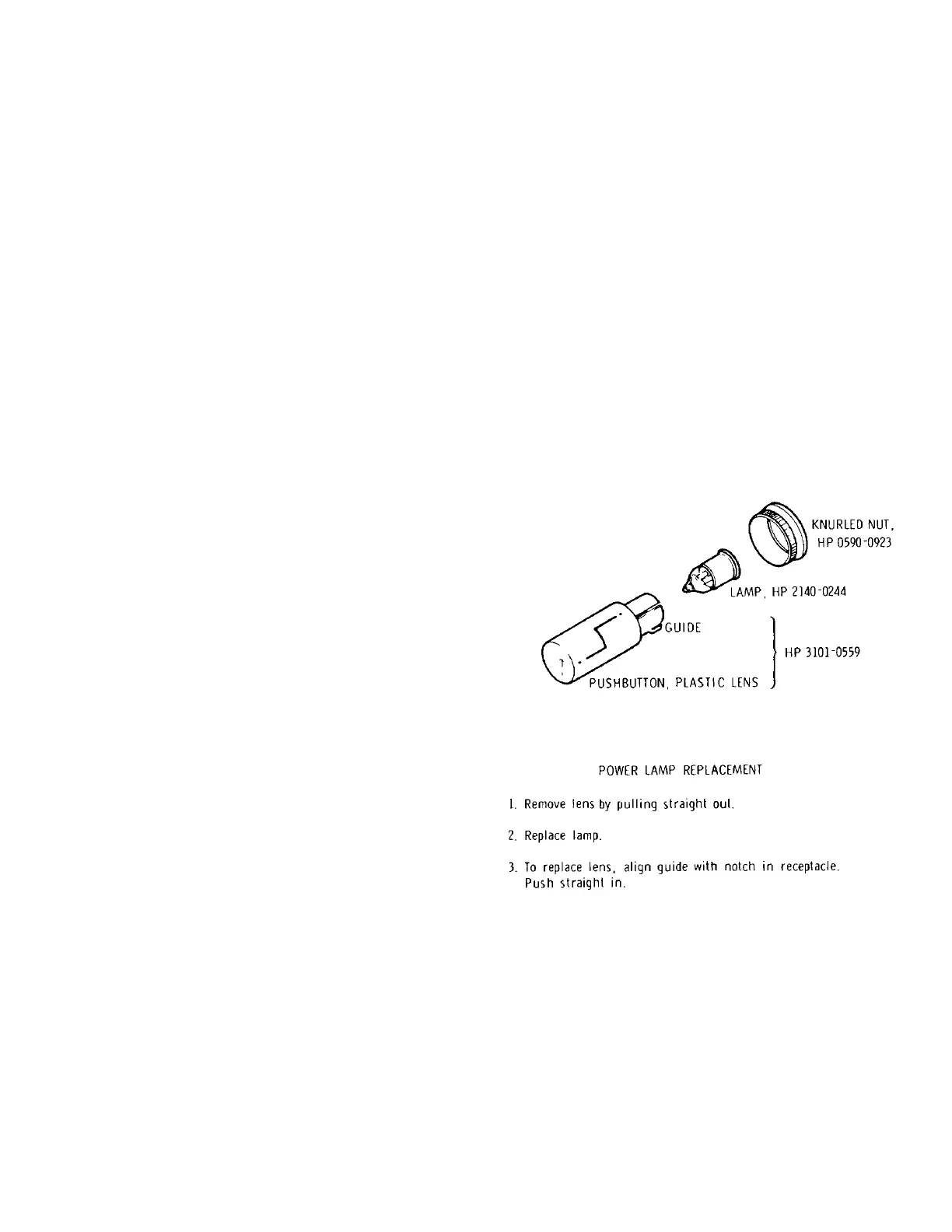

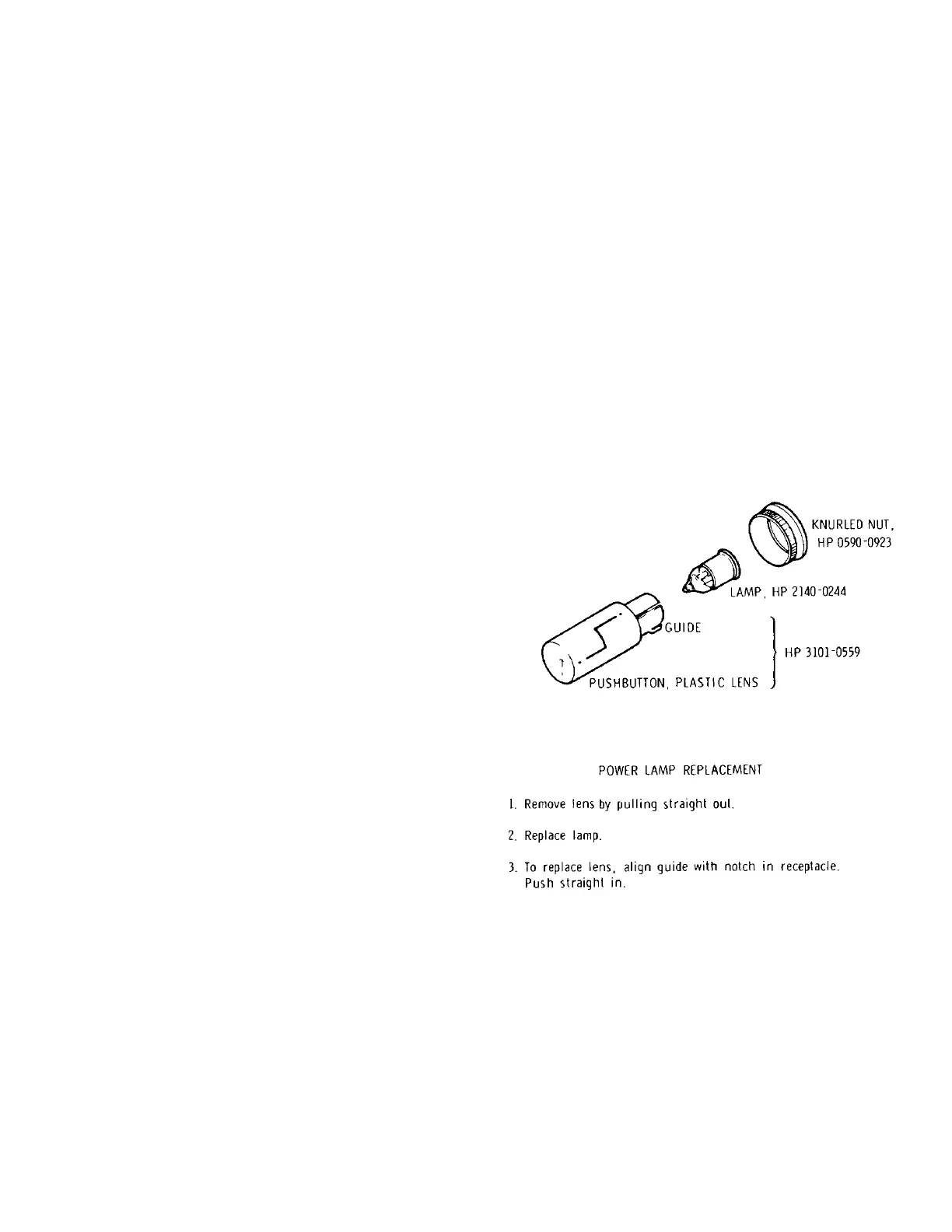

3-13. Lamp Replacement. Figure 3-1 explains how to

replace the lamp located in the line power switch.

3-14. Meter Zeroing. To mechanically zero the front

panel meter, set LINE switch to OFF and place

instrument in its normal operating position. Turn

adjustment screw cw until indicator indicates zero, then

turn adjustment slightly ccw to free mechanism from

adjusting peg.

Figure 3-1. Lamp Replacement.

3-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...