MAINTENANCE

PREVENTIVE MAINTENANCE SCHEDULE

6 - 2 I-E96-506B1

®

This section presents procedures that the customer should be

able to perform on site. These preventive maintenance proce-

dures should be used as a guideline to assist in establishing

good preventive maintenance practices. Select the minimum

steps required to meet the cleaning needs of your system.

Personnel performing preventive maintenance should meet the

following qualifications.

•

Maintenance personnel should be qualified electrical tech-

nicians or engineers that know the proper use of test equip-

ment such as digital multimeters.

•

Maintenance personnel should be familiar with the INFI 90

modular power system, have experience working with pro-

cess control systems, and know what precautions to take

when working on live AC systems.

PREVENTIVE MAINTENANCE SCHEDULE

Table 6-1 is the preventive maintenance schedule for the mod-

ular power system. The table lists the preventive maintenance

tasks in groups according to their specified maintenance inter-

val. Some tasks in Table 6-1 are self explanatory. Instructions

for tasks that require further explanation are covered in PRE-

VENTIVE MAINTENANCE PROCEDURES in this section.

NOTE:

The preventive maintenance schedule list is for general pur-

poses only. Your application may require special attention.

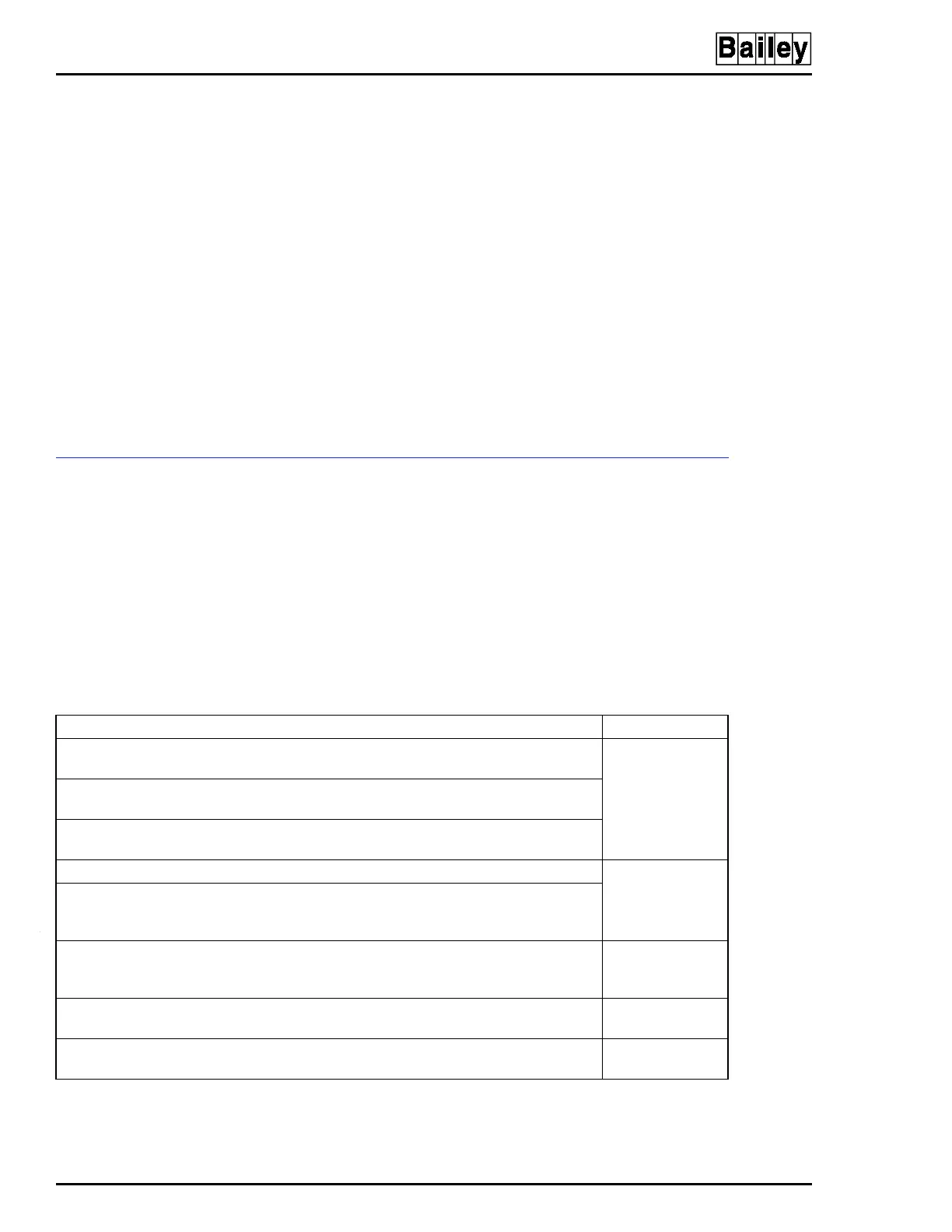

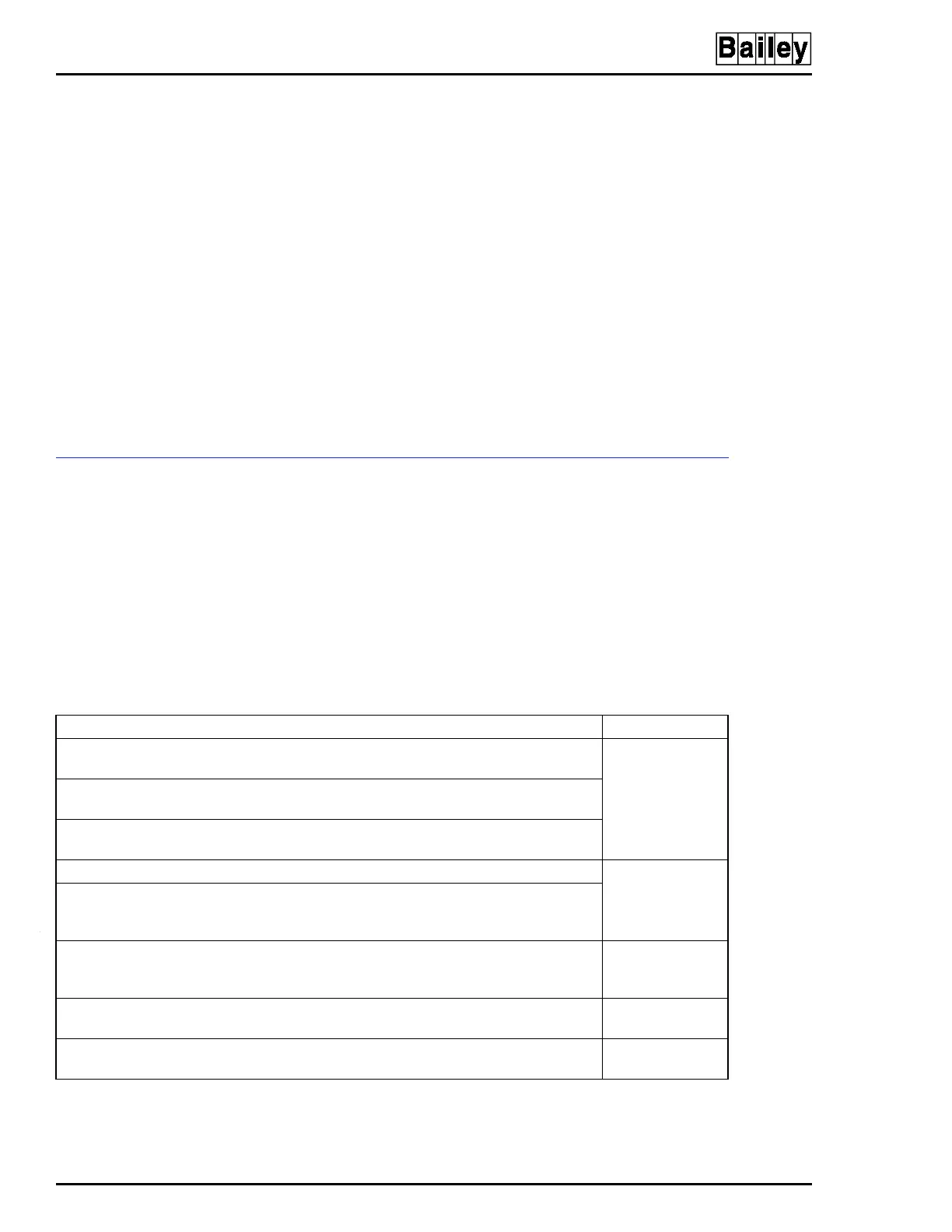

Table 6-1. Preventive Maintenance Schedule

Task Frequency

Check the cabinet air filters. Clean or replace them as necessary. Check the air filter

more frequently in excessively dirty environments. Refer to procedure.

3 months

Check cabinet, power entry panel and power modules for dust. Clean as necessary

using an antistatic vacuum.

Check all signal, power and ground connections within the cabinet and verify that they

are secure. Refer to procedure.

Check modular power supply outputs. Refer to procedure. 6 months

Do a visual inspection of the fan assembly. Verify that all fans are rotating and replace

if necessary. Refer to the appropriate INFI 90 power system manual for replacement

instructions.

Check the quality of the plant power and grounding system. Follow the power and

grounding system verification procedures in the INFI 90 site preparation and planning

instruction.

12 months

Inspect all control, I/O modules and power modules, giving particular attention to power

supply contacts and heat sinks. Clean as necessary. Refer to procedure.

^

Inspect and check the power entry panel. In high vibration environments testing may be

necessary at shorter intervals. Refer to procedure.

2 years

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...