456 9424200994 Rev N

Pickup Verification (I2 Mode)

Step 1: Use BESTCOMSPlus to send the operational settings in Table 204 to the BE1-11g. Reset all

targets.

Table 204. Operational Settings (I2 Mode)

System Parameters, Sensing

Transformers

Protection, Current, Instantaneous

Overcurrent (51-1)

Enables 51-1 function for I2

mode

Protection, Current, Instantaneous

Overcurrent (51-1)

Selects CT circuit 1 as the

source

Target Configuration, Targets

Enables Neg SEQ target

for 51-1

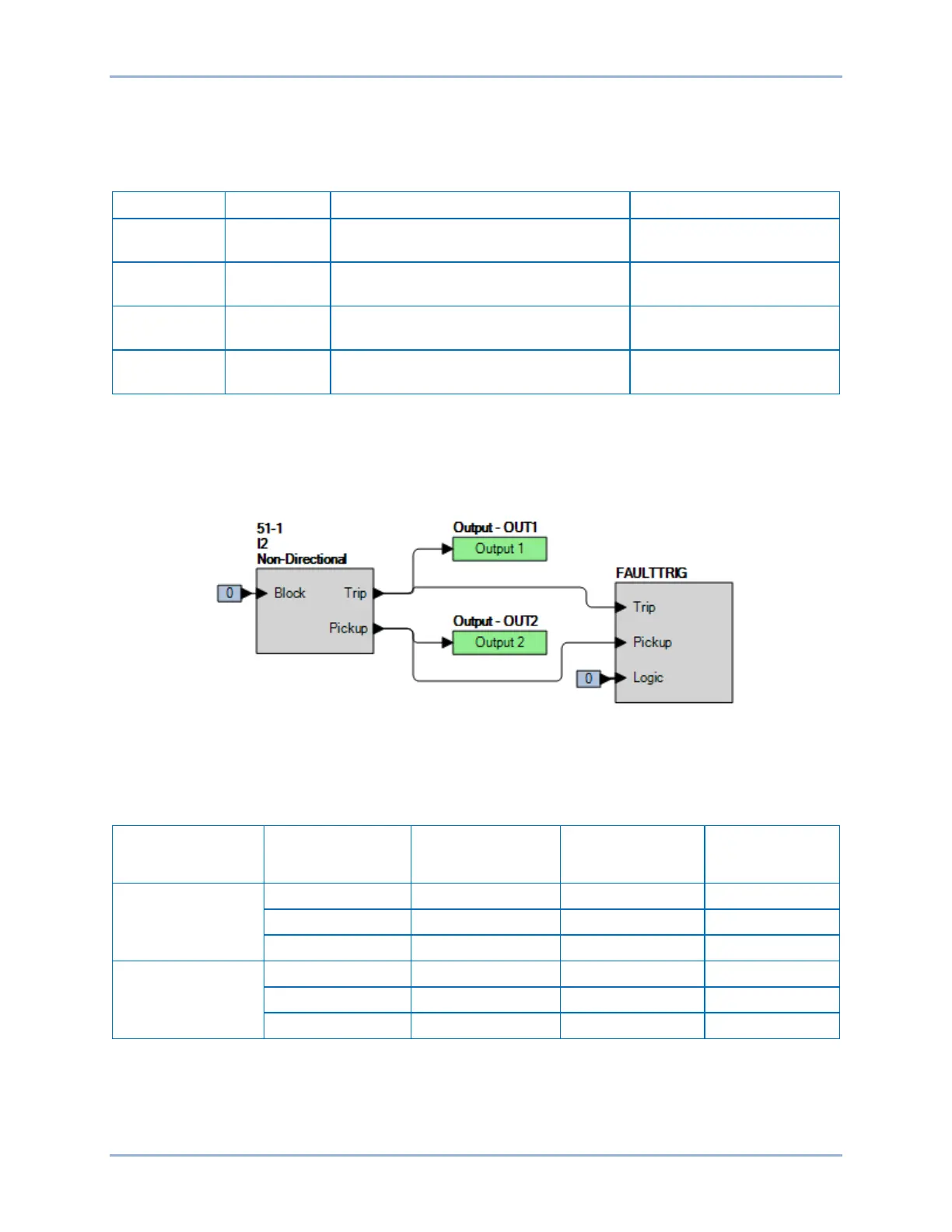

Step 2: Use BESTCOMSPlus to configure the BESTlogicPlus programmable logic shown in Figure 304.

• Blocking is disabled.

• OUT1 closes for 51-1 Trip.

• OUT2 closes for 51-1 Pickup.

• Fault recording is enabled.

Figure 304. BESTlogicPlus Settings (I2 Mode)

Step 3: Use BESTCOMSPlus to open the Protection, Current, Inverse Overcurrent (51-1) screen and

send the low range test settings (minimum pickup setting) to the BE1-11g for your sensing input

type in Table 205.

Table 205. Pickup Test Settings (I2 Mode)

Sensing Input

Type

Range Pickup Setting Time Dial Time Curve

5 A

1 A

Step 4: Prepare to monitor the 51-1 function operation. Operation can be verified by monitoring OUT2

(see Figure 304).

Step 5: Connect a current source to terminals D1 and D2 (A-phase). For a single-phase input test, I2 =

Ia / 3. Therefore, the BE1-11g should pick up at a value of three times the setting value when

applying only a single-phase input. For example, to determine the pickup current value required

Inverse Overcurrent (51) Test BE1-11g

Loading...

Loading...