Chapter 5 Explanations

Mini-Switch LB 471

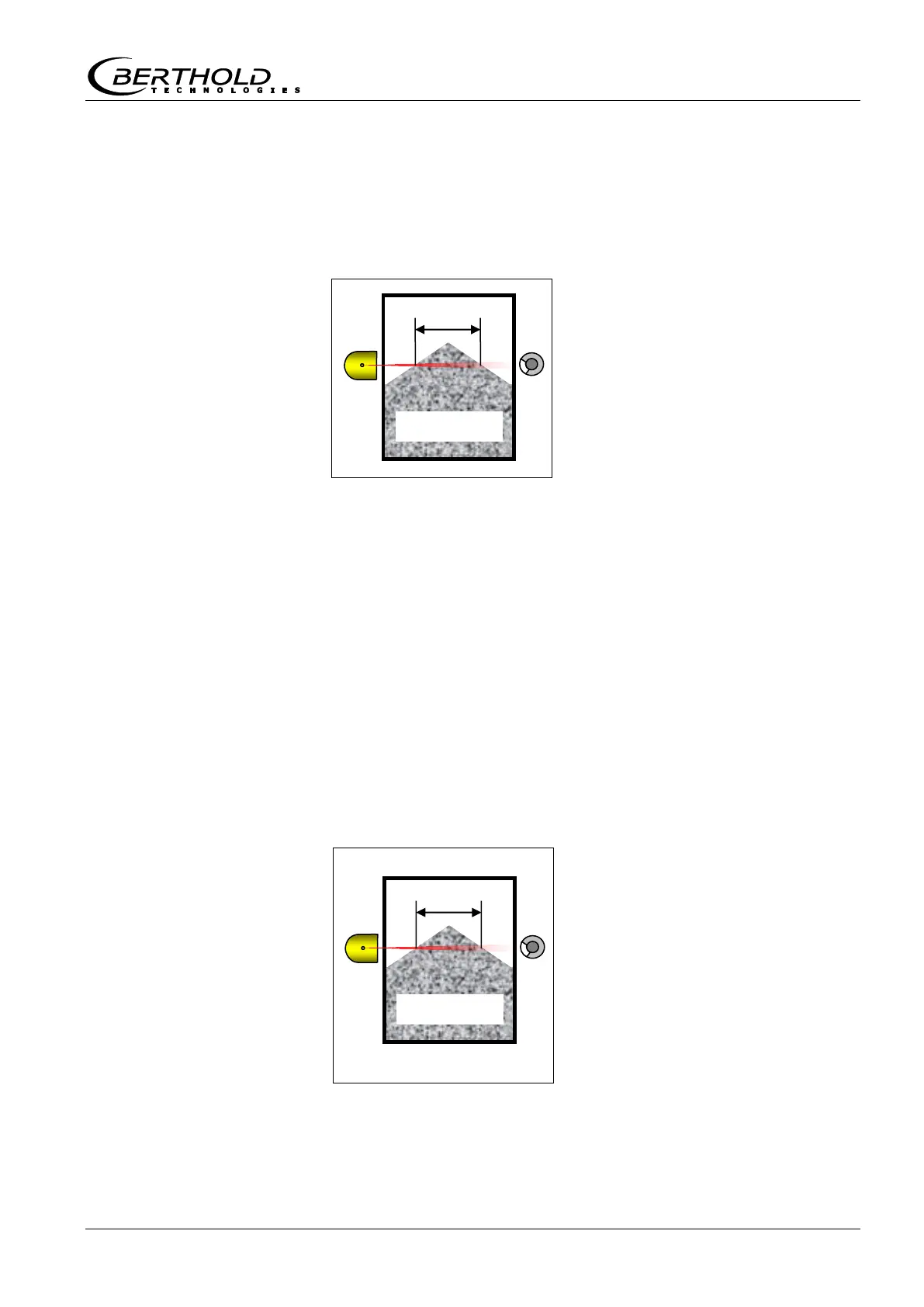

Simulate bulk cone with steel or lead plates

You need steel or lead plates causing the same absorption with

respect to Gamma radiation as the bulk cone. Since this is de-

pendent on the mass per unit area, the steel or lead plate must

have the same mass per unit area as the bulk cone.

The required thickness of the steel plate is determined as follows:

Product coal: 0.5 g/cm

3

Bulk cone diameter: 500 mm

Source: Cs-137

Steel density: 7.8 g/cm³

HVL=0.5x500/7.8=32mm steel

Alternative for lead plate:

HVL=0.5x500/11.3=19mm lead

You may also use several plates in order to get the required thick-

ness of the plate.

The container has to be empty to calculate the switch point, or the

cone end of the bulk cone must be below the monitoring level.

Now use the steel or lead plate and cover the sensitive part of the

detector, i.e. the scintillator. Hold the plate between detector and

container wall. The plate must have the following minimum dimen-

sions in order to cover the entire detector window or the complete

scintillator:

70 x 70 mm for NaI detector

200 x 200 mm for Super-Sens

While the plate is being held in front of the scintillator, read off the

count rate in code 11 and enter this value in code 18.

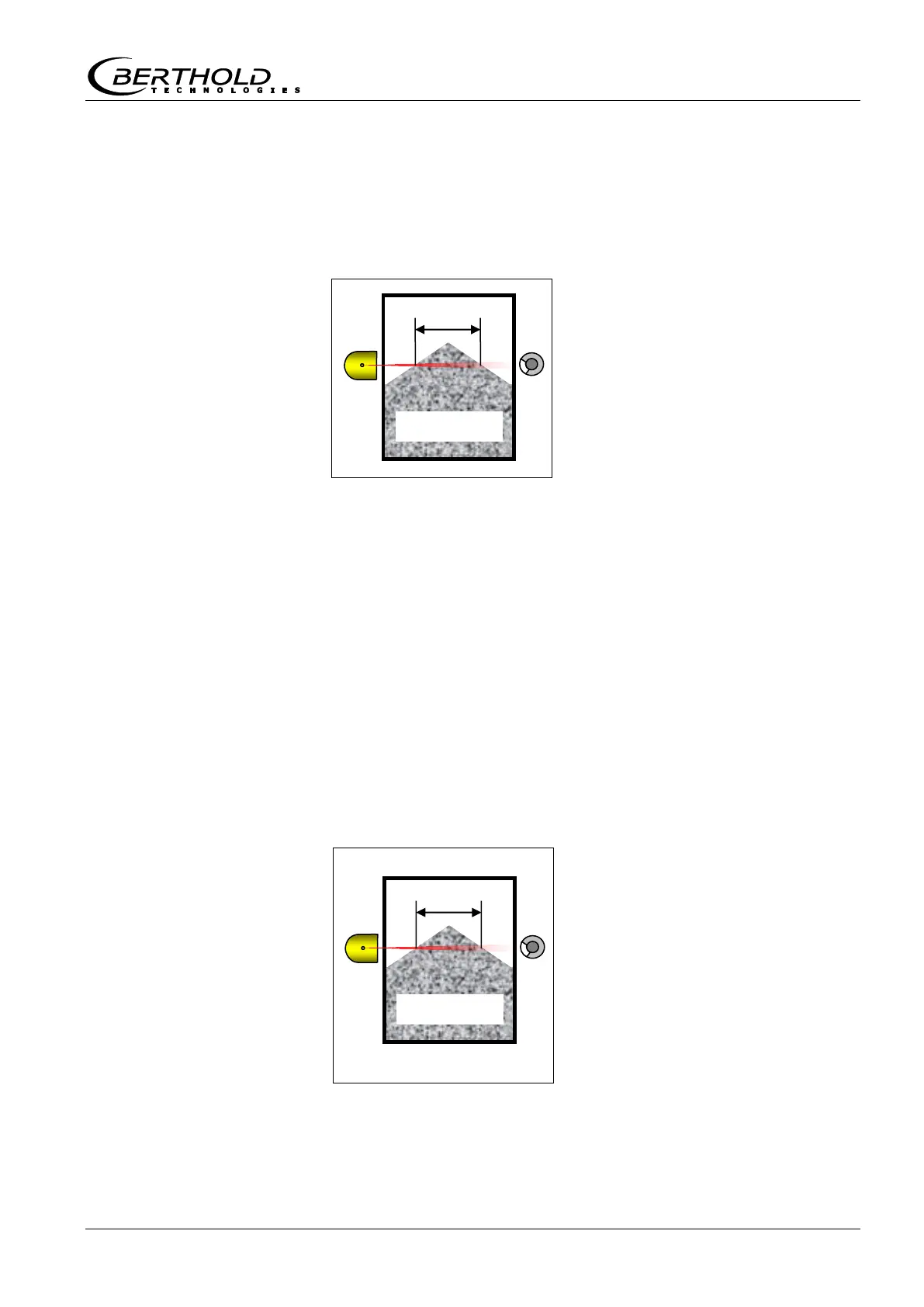

Calculating the count rate for the switch point

Example with coal

Bulk weight (rho): 0.5 g/cm³

Bulk cone diameter: 50cm

µ for Co-60 source: 0.04

(µ for Cs-137 source: 0.057)

Empty count rate: 300 cps

Full count rate: 40 cps

I

use

= I

empty

– I

full

I

use

= 300-40 = 260 cps

I = I

full

+ I

use

e

–(µ*rho*d)

I = 40+260*e

–(0.04*0.5*50)

= 136 cps

Input into code 18: 136

Determining the

plate thickness

Calculating the

switch point

Bulk density:

0.5 (g/cm³)

Bulk density:

0.5 (g/cm³)

Loading...

Loading...