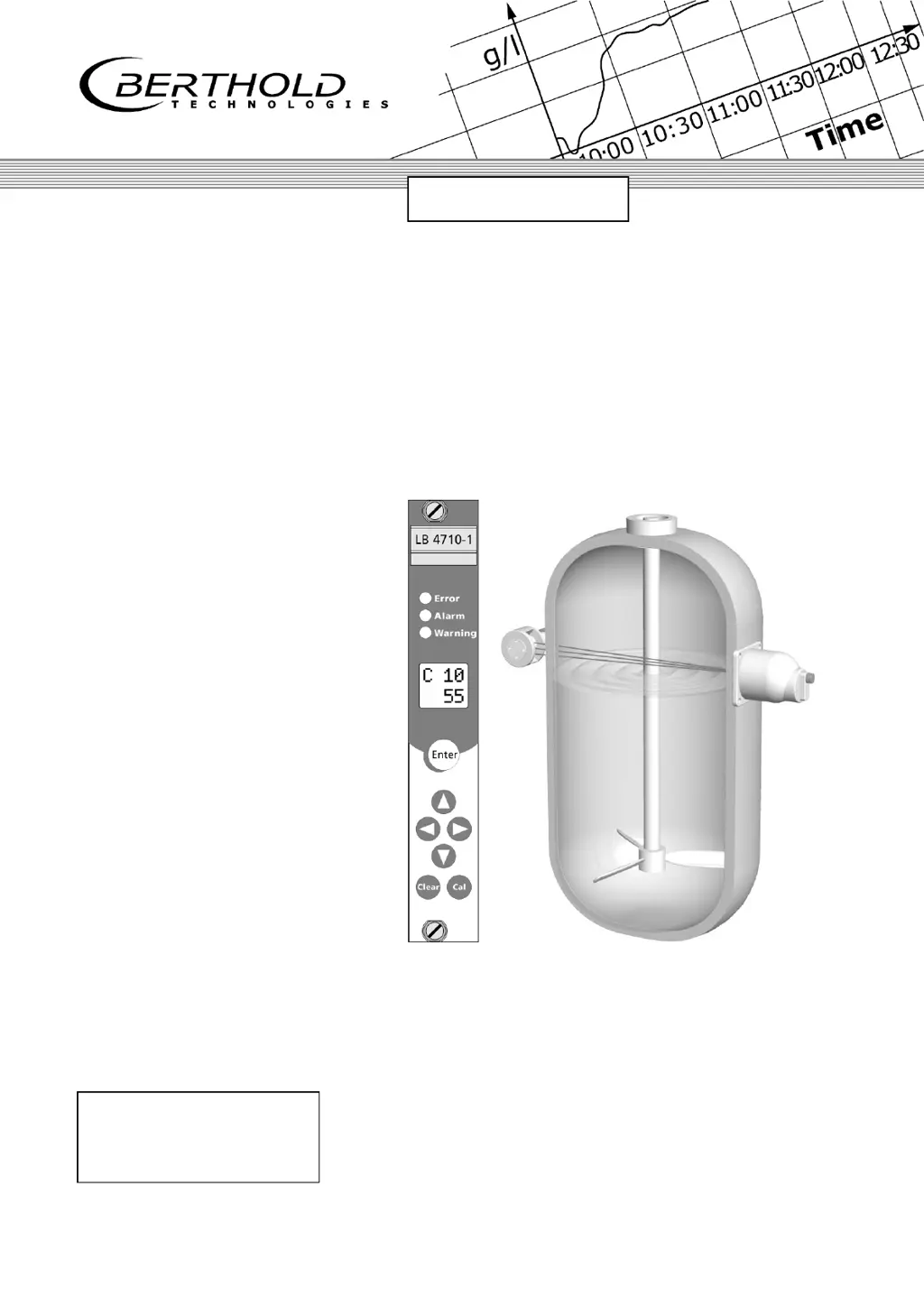

Why does the display vary too much on my BERTHOLD TECHNOLOGIES LB4710-080?

- Cchristina93Aug 9, 2025

If the display varies too much on your BERTHOLD TECHNOLOGIES Switch, it could be due to several reasons. The time constant might be too small, in which case you should increase it. Another cause could be a count rate that is too low, so you should check the source age and irradiation level and replace the detector. Finally, detector stabilization may be faulty, so consider replacing the detector.