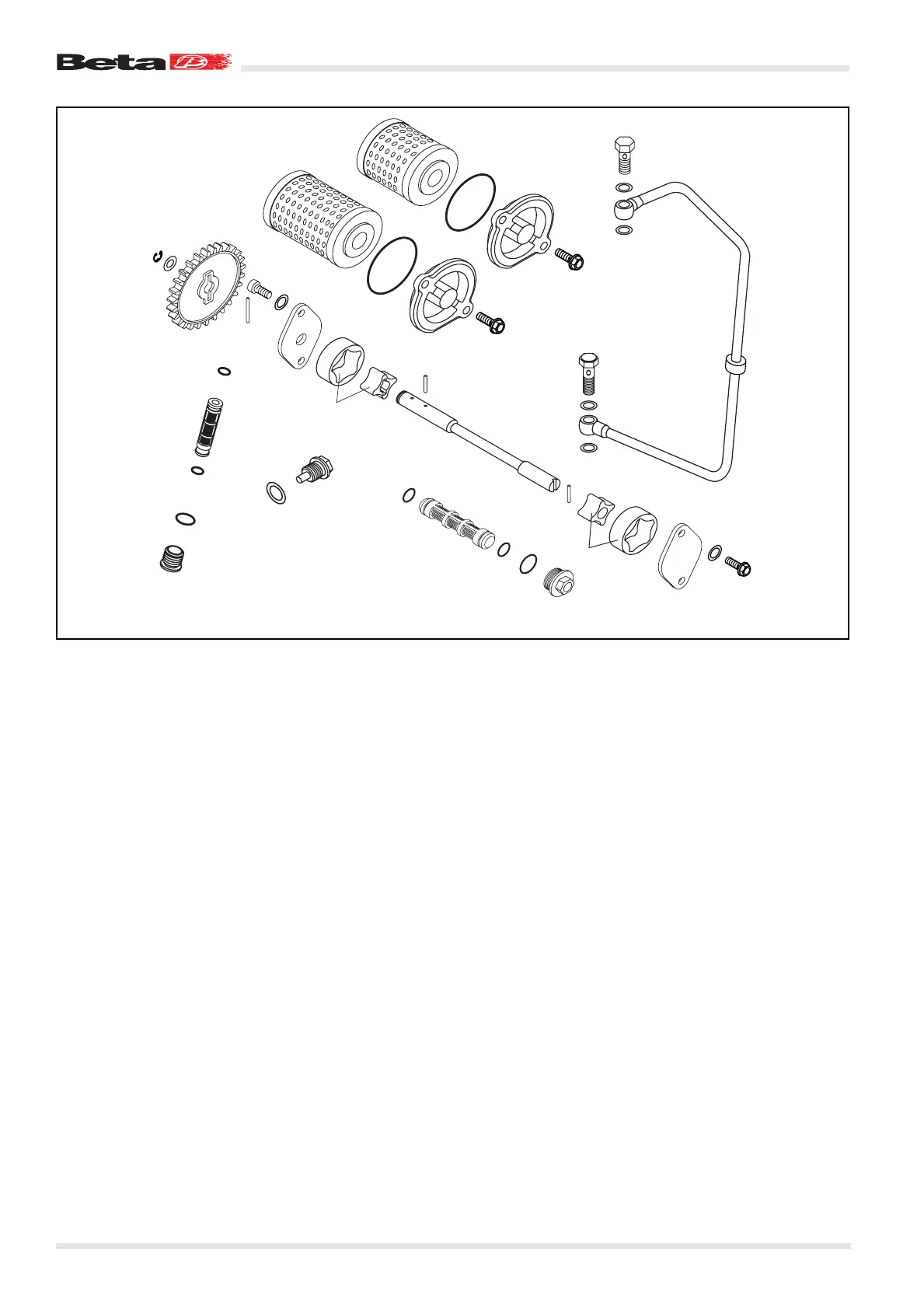

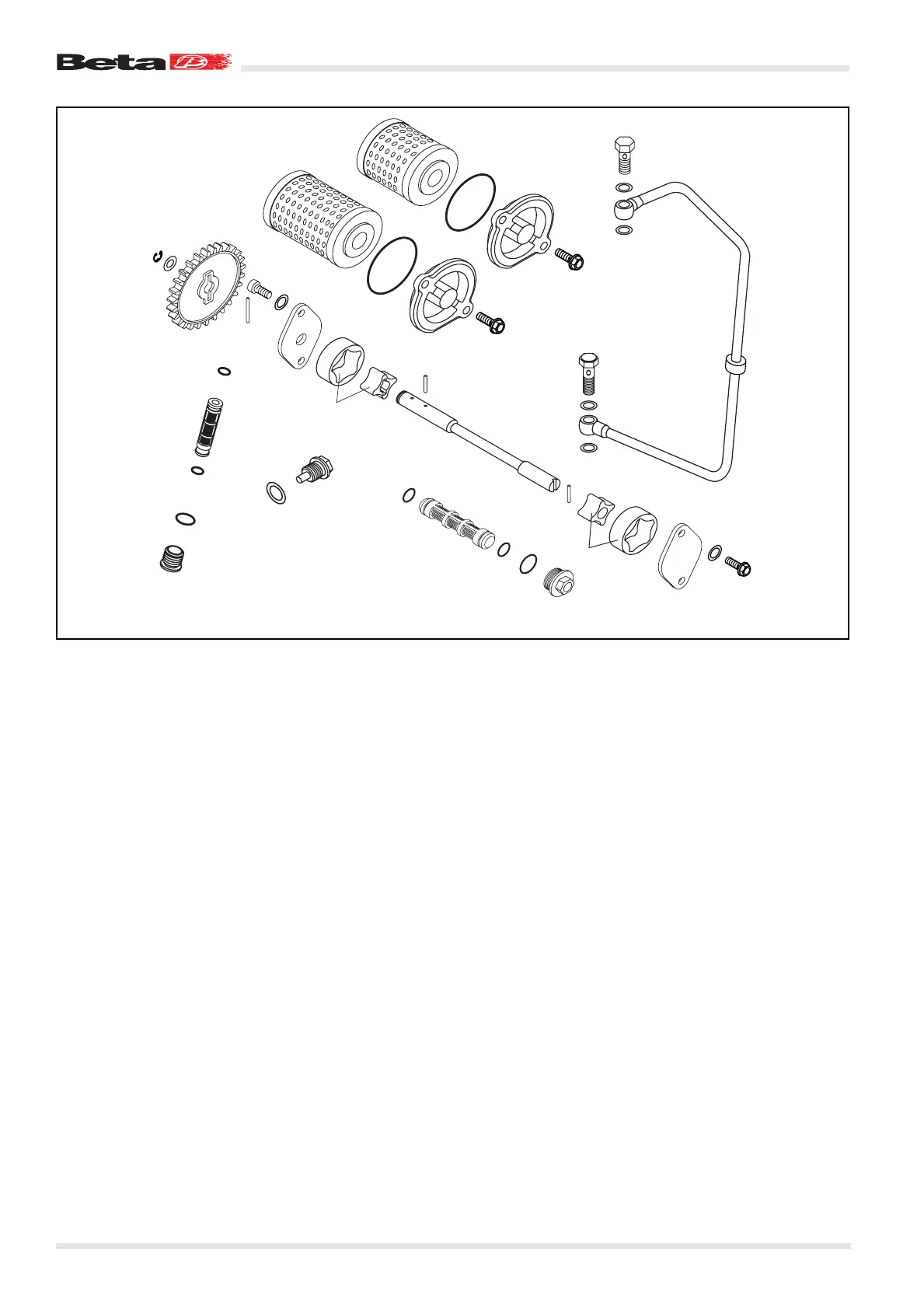

Lubrication system

Oil line 1

Ensure that the soldered joints present no capillary cracks. Blow the oil line with compressed air to check whether the pas-

sage is clear. Also check that there are no friction points on the oil line. Always replace the seal rings with new ones

(8x12x1).

O-ring 2

At each oil change, also replace the O-rings.

Oil pump cover 3

Check the inside for signs of seizure caused by the oil pump rotors and if necessary replace.

Oil pump shaft 4

Place the shaft on a flat surface and check its offset.

Oil pump gear 5

Check the teeth for wear. The roller seat should not be damaged.

Oil units 6

Clean the two oil units with low-pressure compressed air.

O-rings 7

Check their porosity and if necessary replace them.

Oil pump rotors 8

Insert the oil pump rotors in the crankcase and check them as shown in the figure on the previous page. No particles

should stick to the rotors.

Loading...

Loading...