Gearbox

Clamp the driving shaft and the driven shaft in vices (using protective jaws). Remove

the gears and check if the following parts show signs of wear or seizure:

• Needle roller cages.

• Bearing surfaces of the driving shaft, driven shaft and idler gears.

• Gear couplings.

• Sides of all gear teeth.

• Tooth profile of the driving and driven shafts and of the related gears.

• Check that the profiles of all the gears can move smoothly.

Thoroughly clean all the parts and replace any faulty components.

Always fit new Seeger rings whenever the gearbox is repaired.

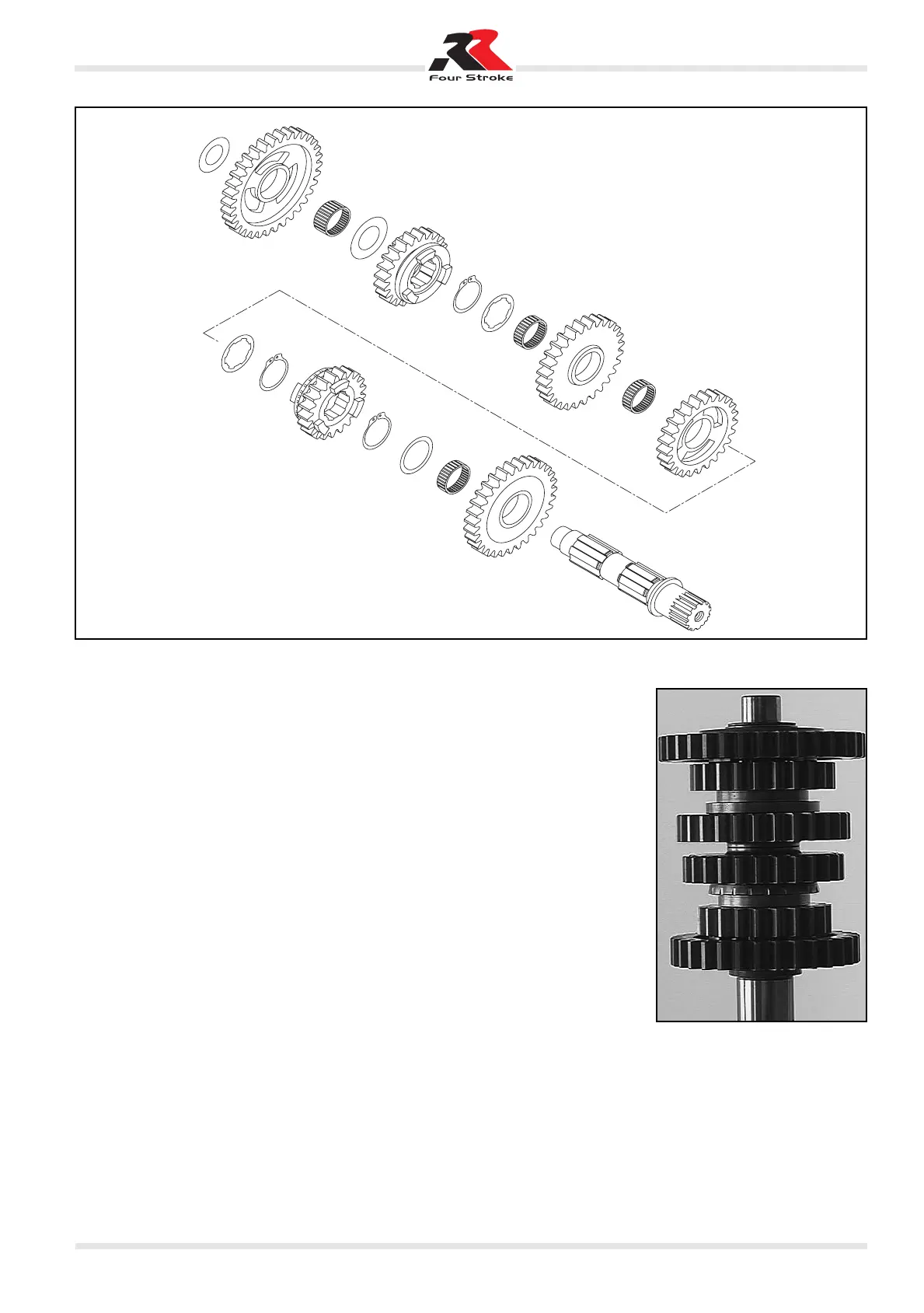

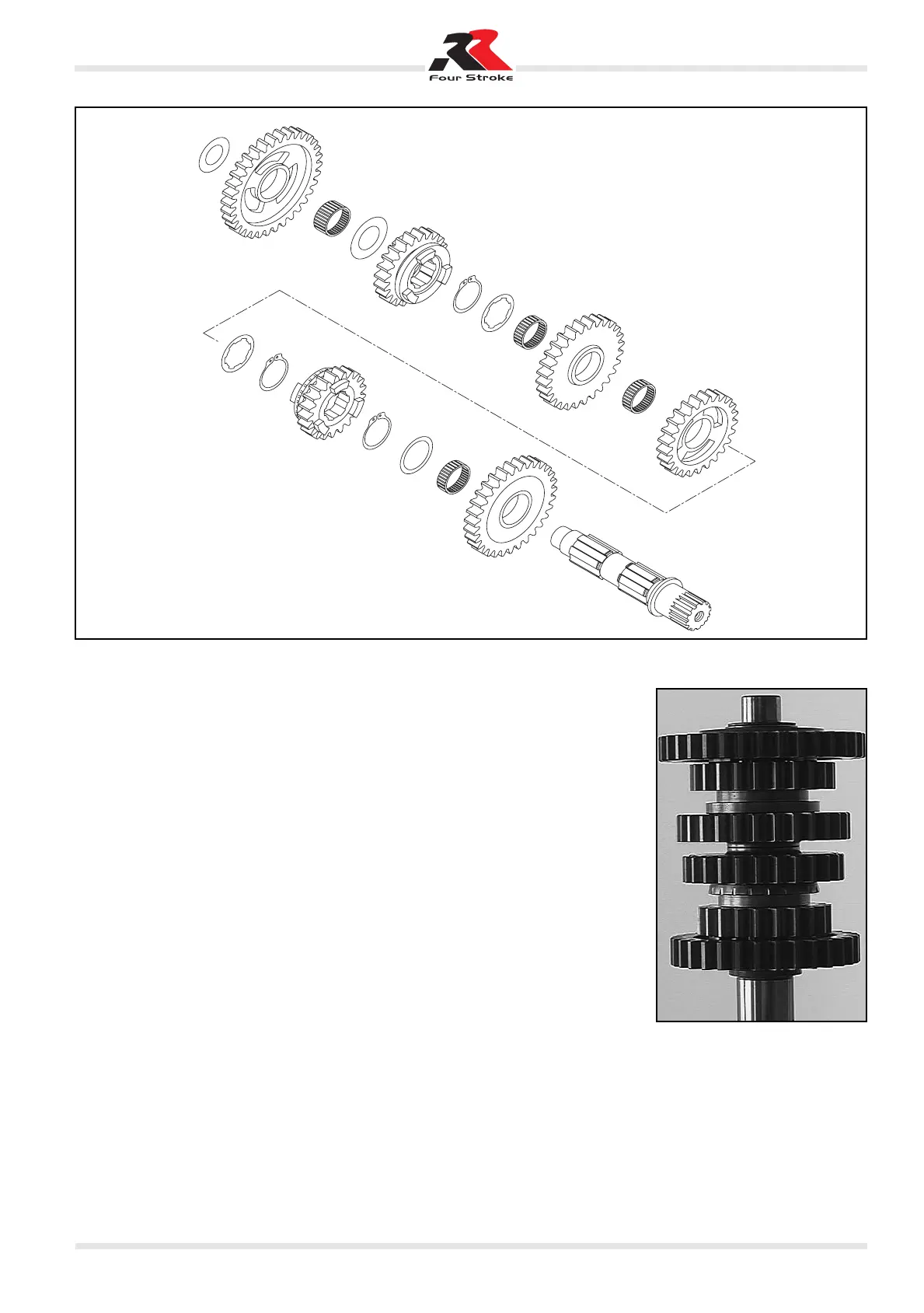

Assembling the driven shaft

– Clamp the driving shaft in a vice with its grooved end facing downwards (use pro-

tective jaws).

– Carefully oil all components before assembling them.

– Fit needle roller cage 2 and 2nd-speed idler gear 1 on the driven shaft with the slot

for the front couplings facing upwards.

– Insert thrust washer 3 (25.2x32x1.5 mm) and Seeger ring 4 with the sharp edge fa-

cing upwards.

– Fit 6th-speed sliding gear 5 with the fork slot facing upwards.

– Fit Seeger ring 6 and toothed washer 7 (25.2x32x1.5 mm).

– Fit two-piece needle roller cage 9 + 11 and 4th-speed idler gear 8 with the slot for

the front couplings facing downwards.

– Fit 3rd-speed idler gear 10 with the slot for the front couplings facing upwards.

– Fit toothed washer 12 (25.2x32x1.5 mm) and Seeger ring 13.

– Fit 5th-speed sliding gear 14 with the fork slot facing downwards and thrust washer

15 (20x32x1 mm).

– Fit needle roller cage 16, 1st-speed idler gear 17 with the slot facing downwards and

thrust washer 18 (17.2x30x1.5 mm).

Loading...

Loading...