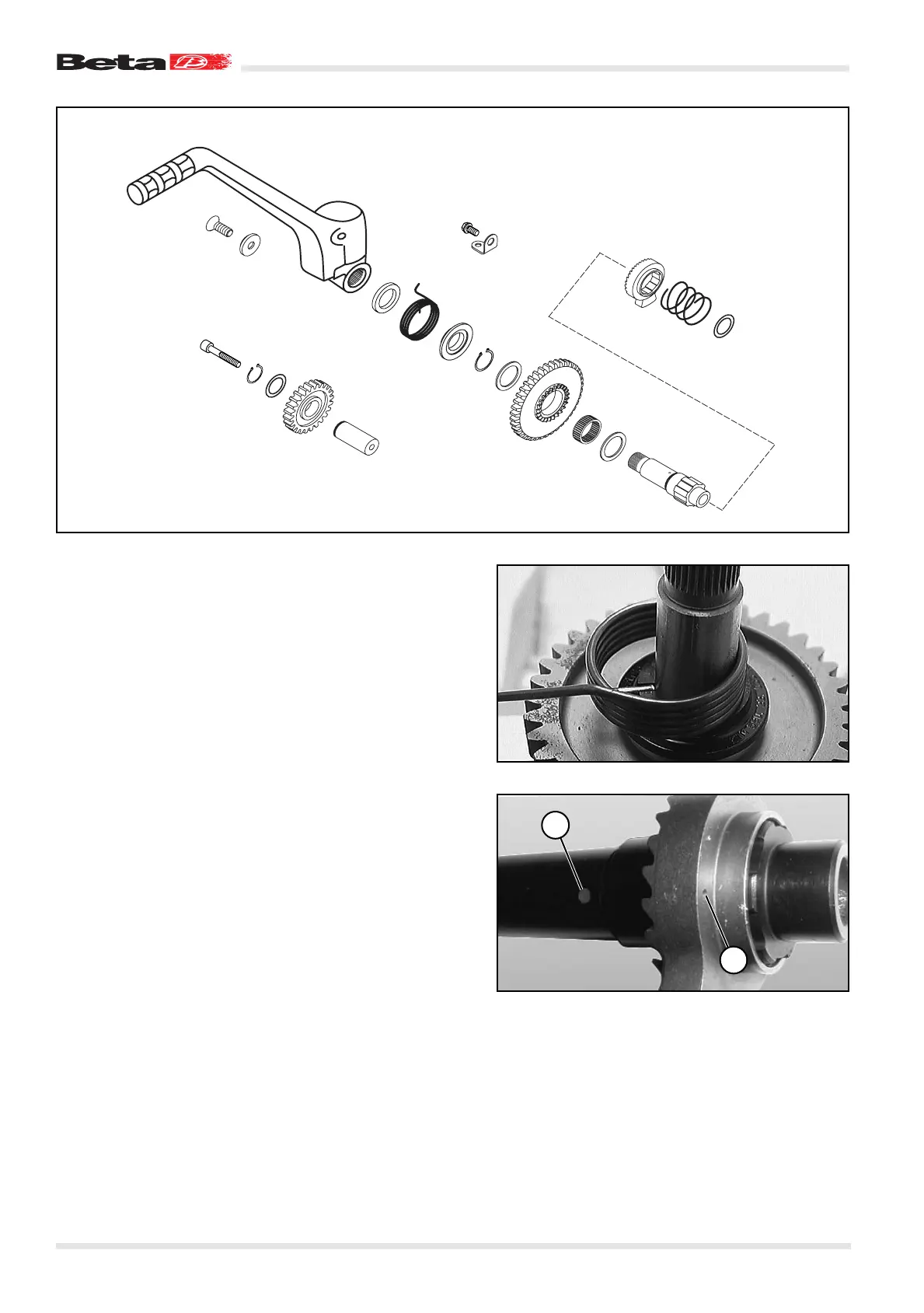

Checking the kickstart for wear

Remove all components from the kickstart shaft and clean them.

Starter gear 1

Check the wear of the teeth and the play of the support.

Starter idler gear 2

Check to see if there is any play or any sign of seizure on the sup-

port. Check the wear of the teeth, which are in constant mesh with

the clutch drum.

Starter coupling 3

Check the inclined surface and the teeth for signs of wear.

Kickstart shaft 4

Check the support points and the teeth for signs of wear or da-

mage and ensure that the starter gear oil hole is clear.

Preassembling the kickstart shaft

– Clamp kickstart shaft 4 in a vice (using protective jaws), with

its toothed end facing upwards.

– Fit thrust washer 5, needle roller cage 6 and starter gear 1

with the stop teeth facing downwards.

– Fit thrust washer 7 and Seeger ring 8 with the sharp edge fa-

cing upwards.

– Fit dragging hub 9 taking care to align its groove with the ho-

le in the kickstart shaft.

– Fit kickstart spring 10, inserting its inside end into the hub

groove and the kickstart shaft hole.

– Remove the kickstart shaft from the vice.

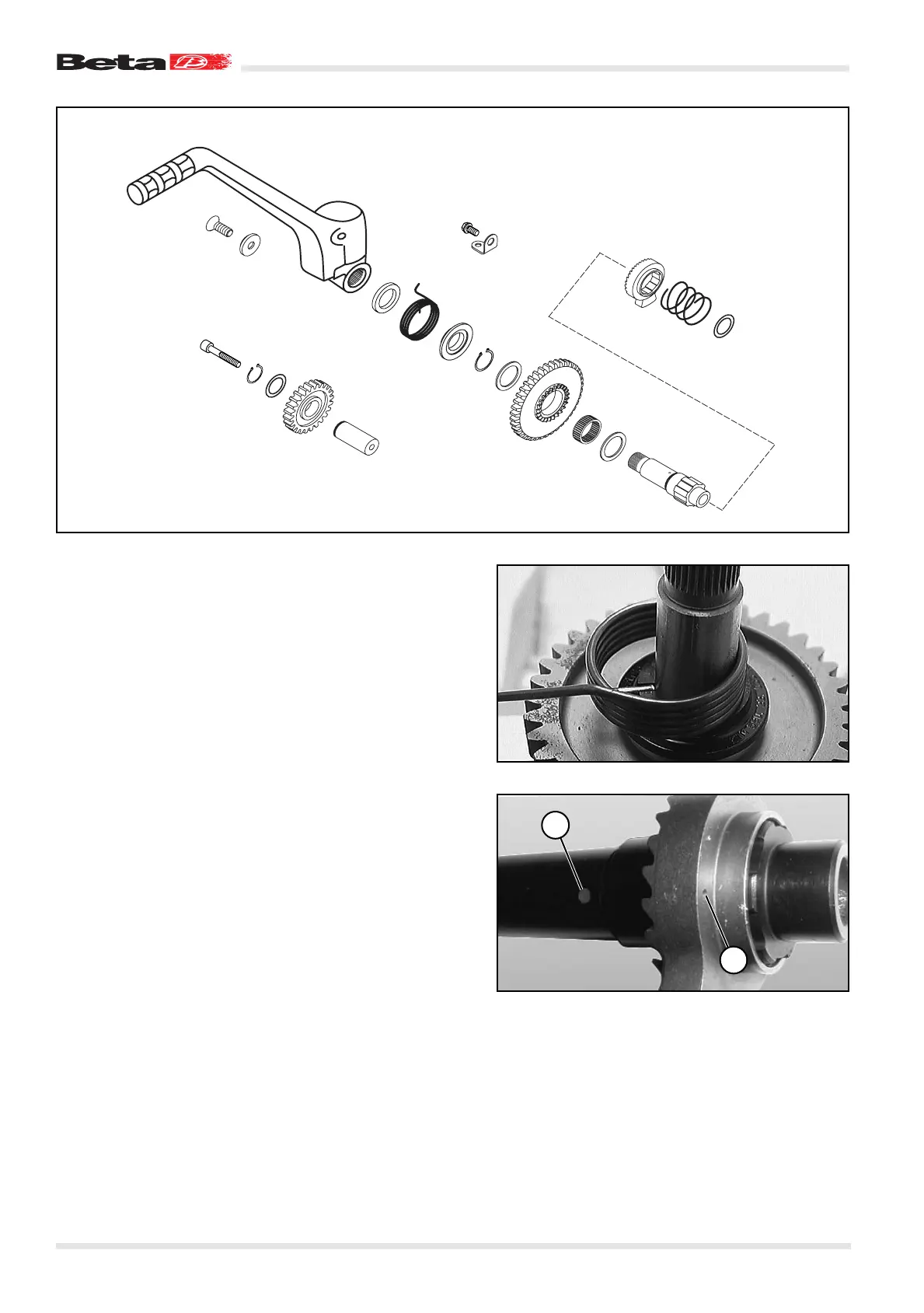

– Fit starter coupling 3 on the kickstart shaft taking care to align

mark A on the starter coupling with oil hole B in the kickstart

shaft.

– Fit the kickstart shaft with starter coupling spring 11 and thru-

st washer 12.

B

A

Loading...

Loading...