Assembling the crankcase

– Remove the engine retainer from the stand.

– Apply a thin film of grease to the crankcase sealing surface

and fit a new gasket.

– Lay down the left-hand crankcase half and tap it with a plastic

mallet until it is properly positioned.

– Ensure that the crankcase gasket is properly seated.

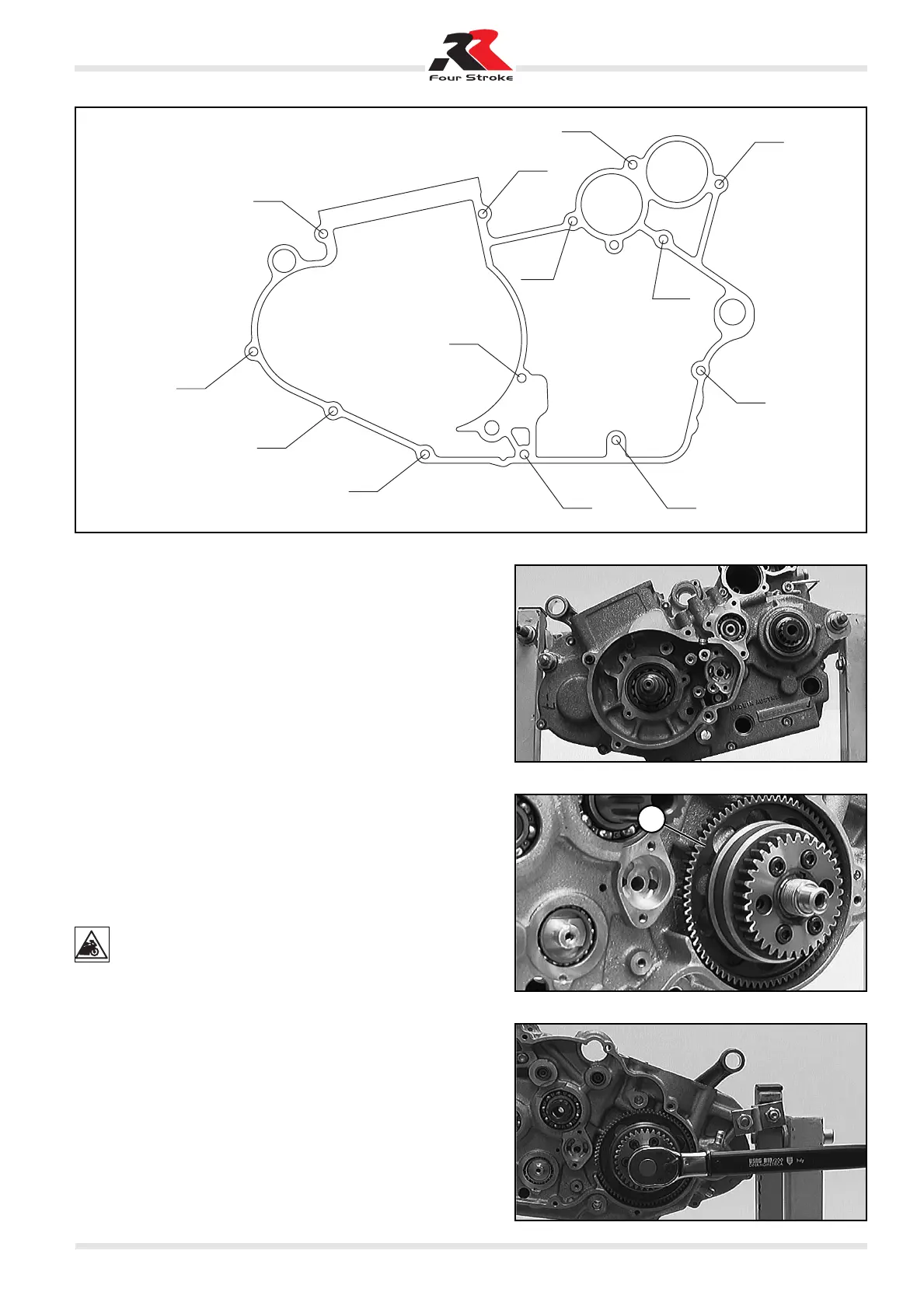

– Grease the crankcase screws, their threads and the cylinder

head resting surface. Fit the screws and tighten them (for the

lengths of the screws, refer to the diagram).

– Check that all the shafts can move smoothly before and after

tightening the crankcase screws to 10 N·m.

– Clamp the engine in the stand.

– Accurately cut off the gasket that protrudes from the cylinder

base and the sealing surfaces.

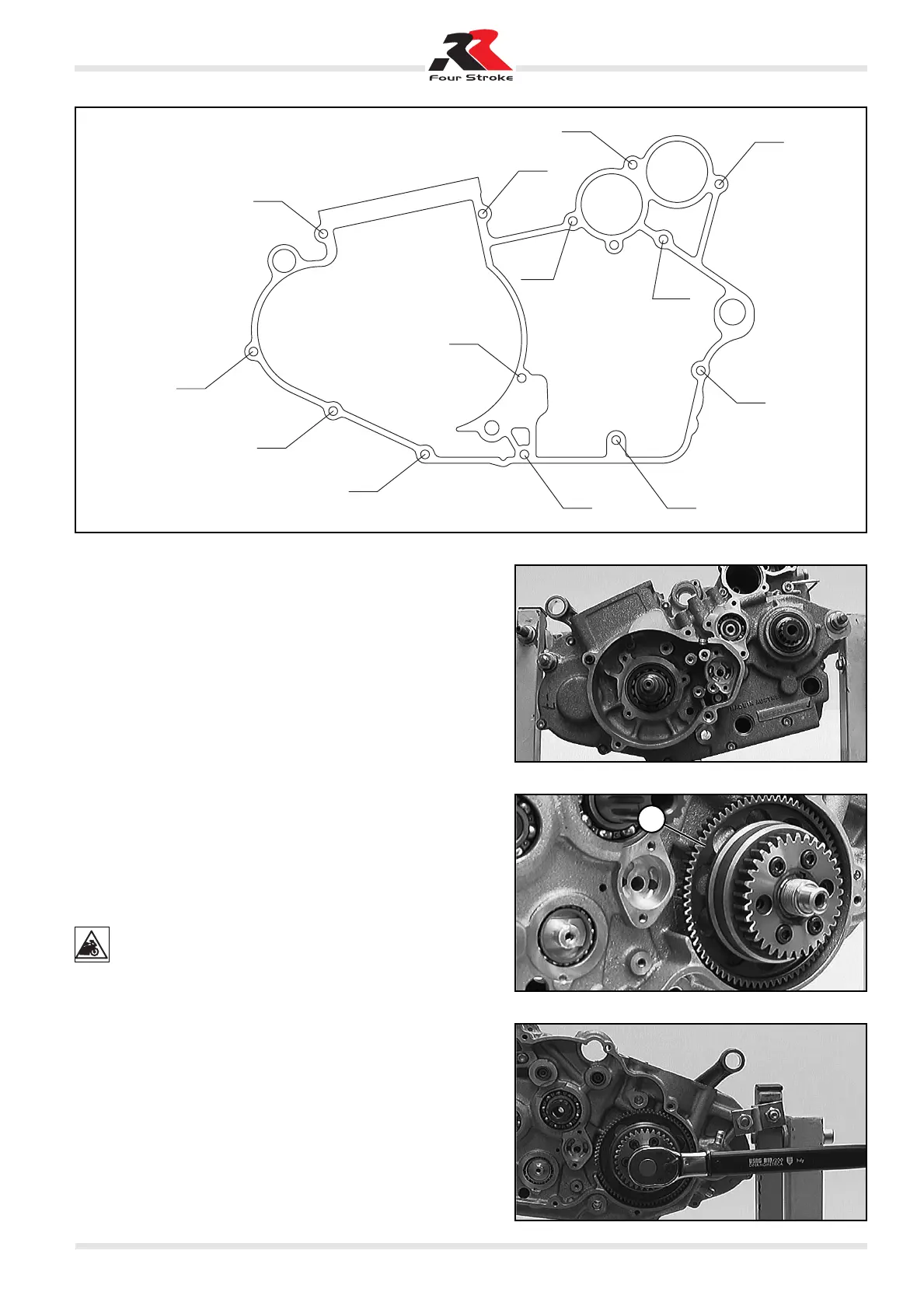

– Check to see if the key is fitted to the crankshaft.

– Carefully oil the free wheel and the needle roller cage in the

free wheel gear.

– Insert free wheel gear 1 into the free wheel hub and fit all the

components together on the crankshaft.

The primary pinion flange nut will be fitted at a later stage.

1

NOTE: This diagram shows all the

lengths of the carter fixing screws.

Loading...

Loading...