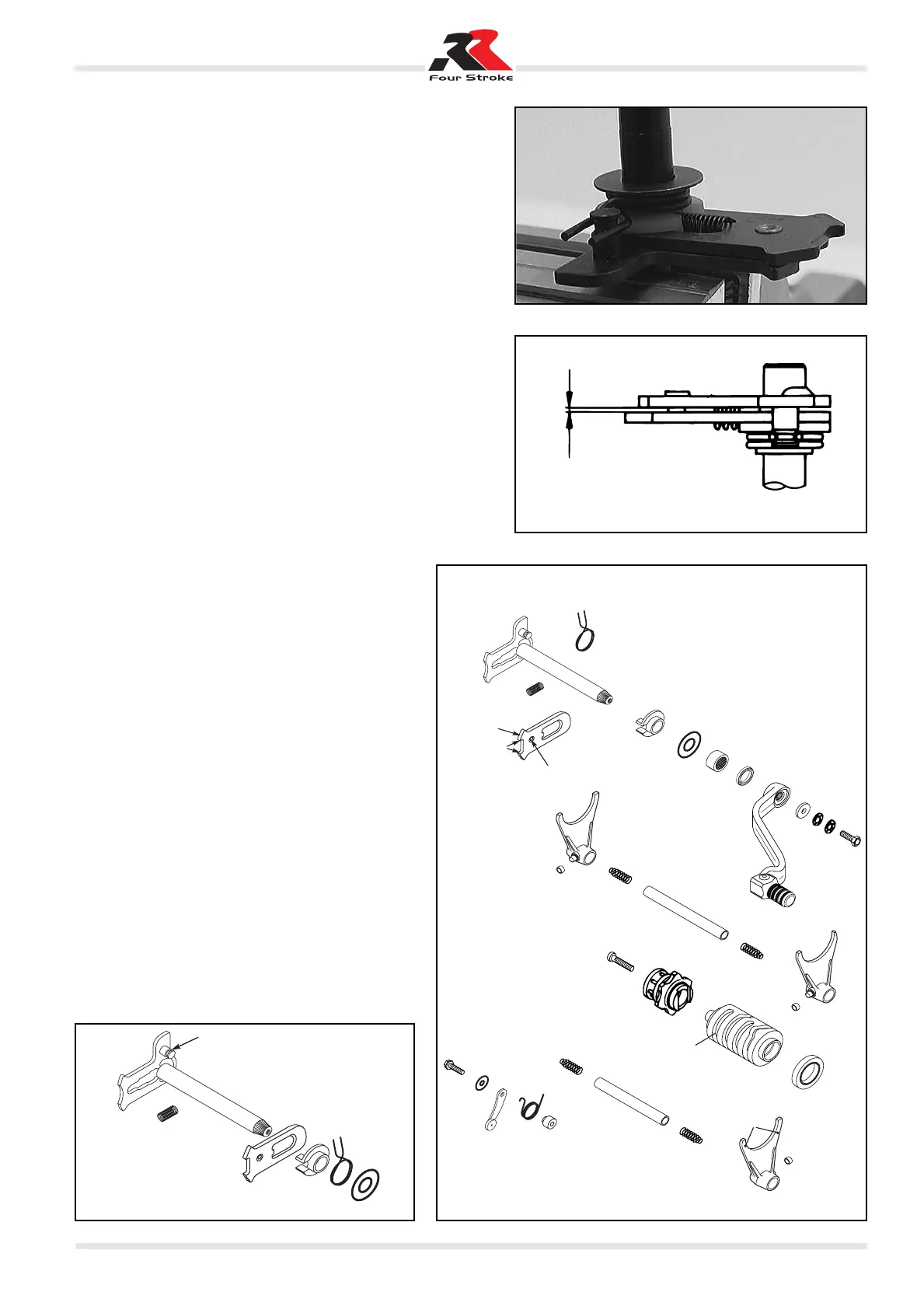

Gearshift mechanism

Gearshift forks 1

Check wear at ends A. When the forks are new, their thickness

ranges from 4.8 to 4.9 mm. The wear limit is 4.6 mm.

Desmodromic mechanism 2

Check the wear of profiled grooves B.

Check the desmodromic mechanism support in ball bearing 3.

Ball bearing 3

Check that it can turn smoothly.

Bushes 4

Ensure that the bushes present no dents or cracks.

Fork guide rods 5

Check the offset of the rods on a flat surface. Check for signs of

scoring or seizure. The gearshift forks should slide freely on the

guide rods.

Selector 6

Check wear at return points C.

Check the wear of selector return surface D (if the surface is

deeply worn, replace the selector).

Check that guide pin E is firmly seated and not worn.

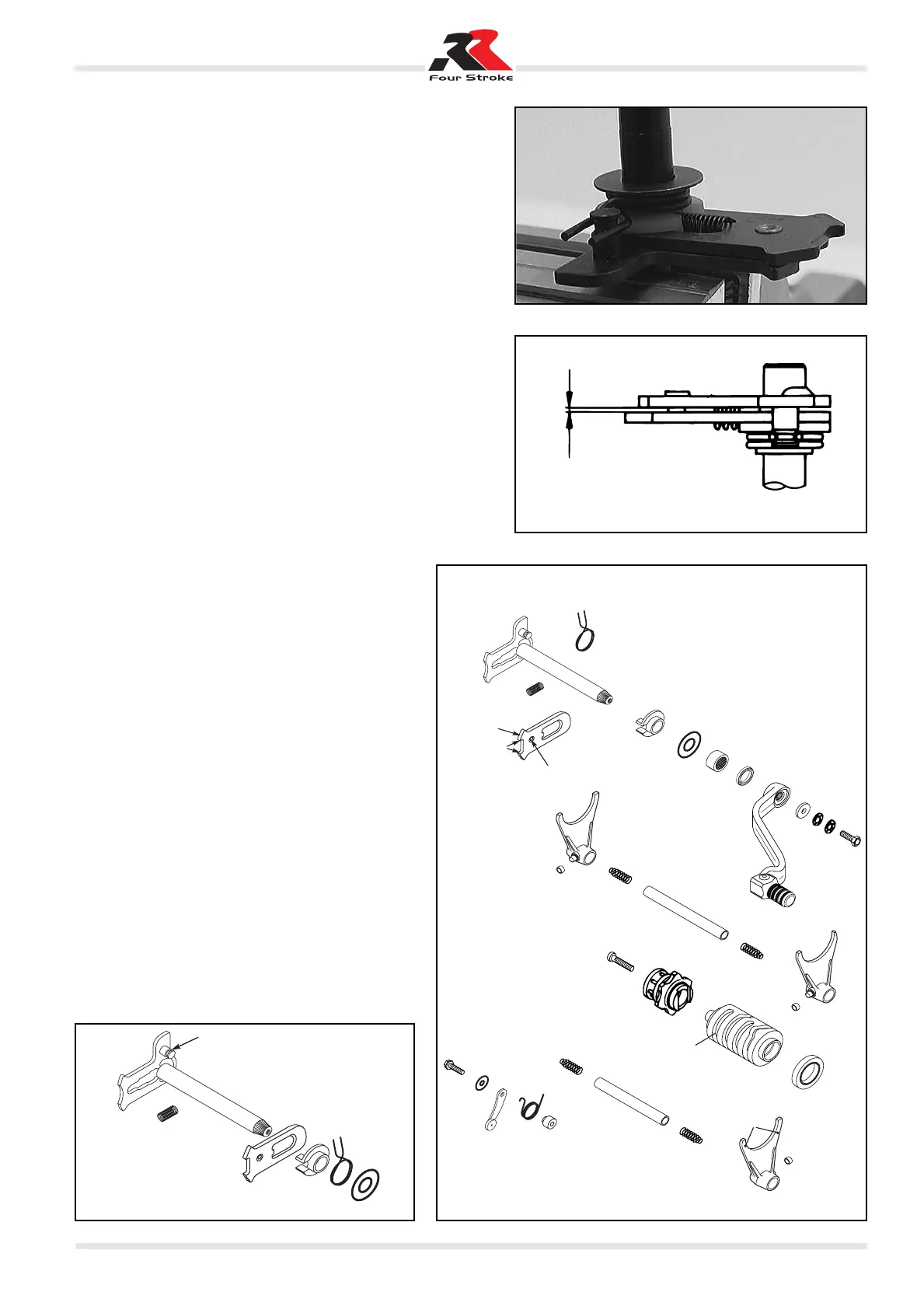

Gearshift mechanism

Preassemble the shaft of the gearshift mechanism and measu-

re clearance F between selector 6 and the guide plate. The play

should be 0.40 - 0.80 mm.

Preassembling the shaft of the gearshift mecha-

nism

– Clamp the short end of the shaft of the gearshift

mechanism in a vice (use protective jaws).

– Fit selector 6 with the guide pin facing downwards

and then attach the guide pin to the guide plate.

– Fit compression spring 7.

– Fit spring holding bush 8, top it with return spring

9 with the bent end facing upwards and then atta-

ch it to pin 11 (see figure).

– Fit thrust washer 10.

Loading...

Loading...