35

6 - Motore Release 01 Date 09/2007

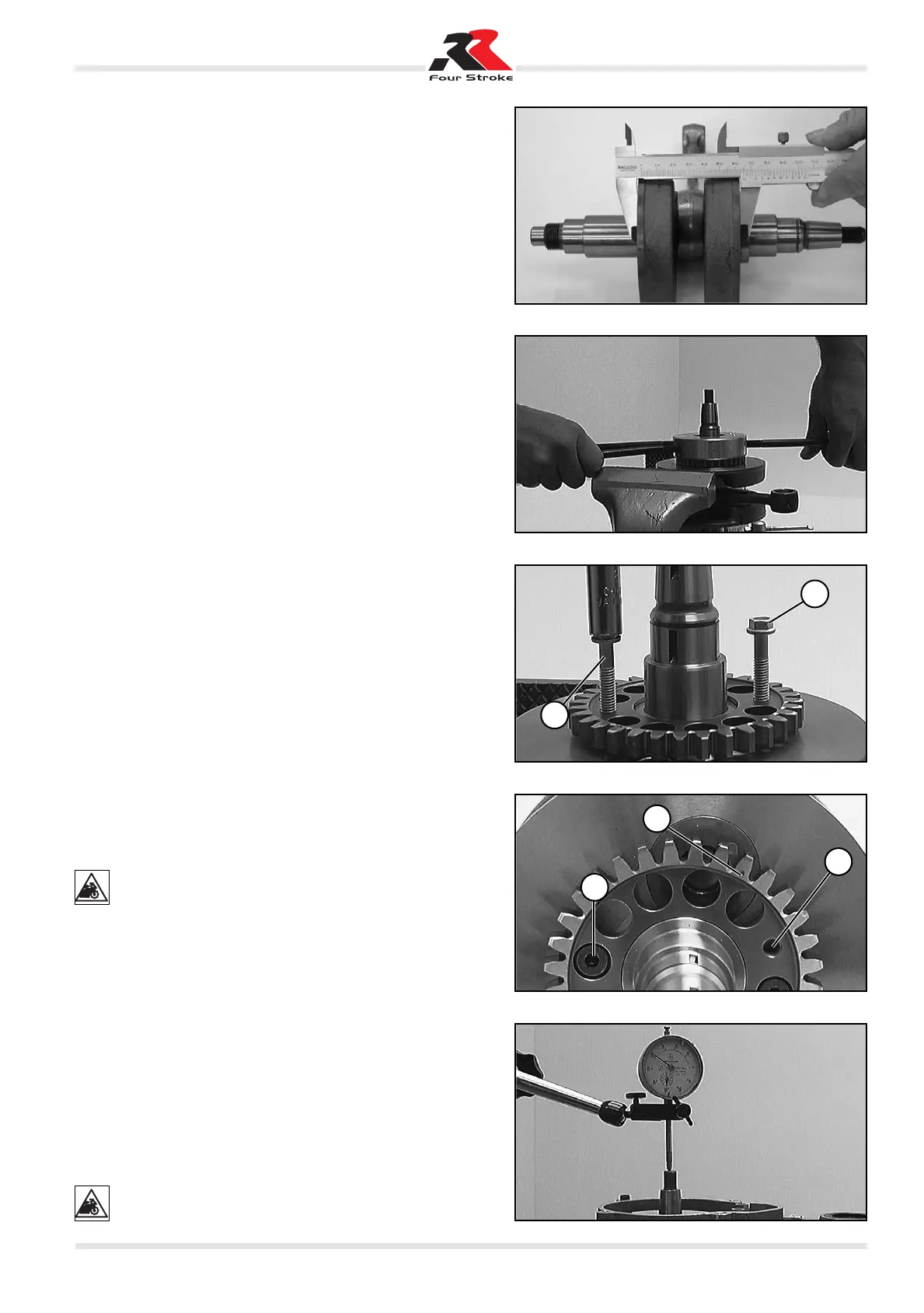

Measuring the outside diameter of the handwheels

Using a vernier caliper, measure the outside diameter of the

handwheels as shown in the figure.

Outside diameter of handwheels = 65 mm ± 0.05 mm

Countershaft gear

– To remove the countershaft gear from the crankshaft, it is first

necessary to remove the inner ring nut of the cylindrical roller

bearing (see below).

– Whenever the cylindrical roller bearings are replaced, the in-

ner collars on the crankshaft also need to be replaced.

– To this end, clamp the crankshaft in a vice by the shaft section

fitting the inner collar to be replaced.

– Heat special tool Part No. 3625193 on an electric hotplate to

approximately 150° C and immediately push it onto the inner

collar. Squeeze the special tool hard to obtain good heat tran-

smission and remove the inner collar from the crankshaft.

– Remove the two screws from the countershaft gear.

– Insert the two screws 1 into M6 threaded holes 2.

– Remove the countershaft gear from the crankshaft and evenly

tighten the two screws.

– Before fitting the countershaft gear, heat it to approximately

100° C.

– Degrease the two countershaft gear fixing screws and apply

Loctite 243 to their threads.

– Fit the countershaft gear to the crankshaft so that mark C is in

the coupling shaft area.

– Fit the fixing screws and tighten to 8 N·m.

– Before fitting a new inner collar, heat the special tool again to

about 150° C, fit it with the inner collar and immediately push

it onto the shaft section.

– Allow the inner collar to cool down for about 30 seconds and

then, using a suitable tube, hit the inner collar until it is seated

properly.

– After replacing the inner collars, measure the crankshaft axial

play.

NEVER ATTEMPT TO INSERT AN INNER COLLAR BY

HITTING IT WHILE THE CRANKSHAFT IS HELD IN A VI-

CE BY A SHAFT SECTION. THIS WOULD RISK COM-

PRESSING THE SHAFT SECTIONS, MAKING THE CRANK-

SHAFT UNUSABLE.

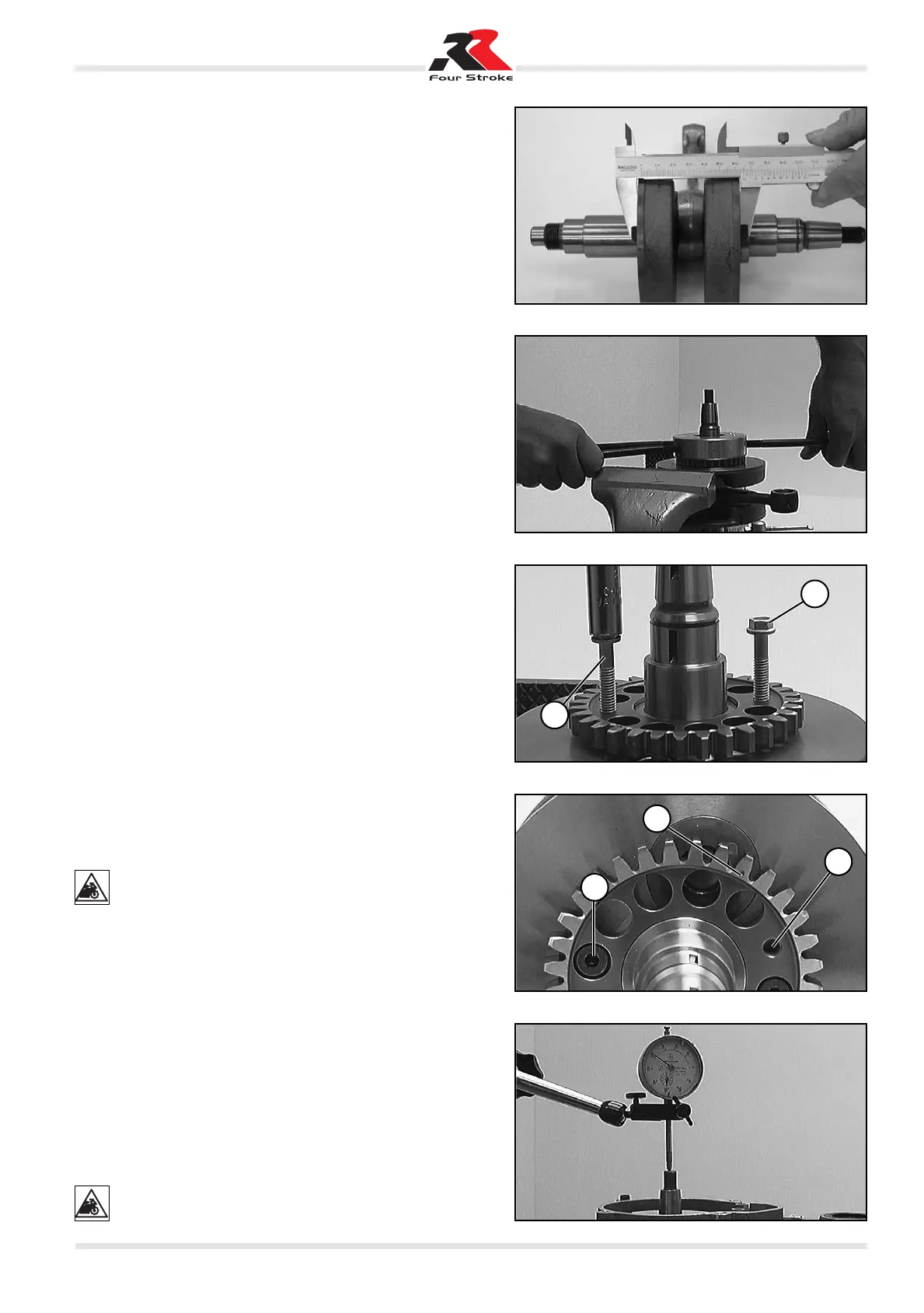

Compensating for the crankshaft axial play

– Insert the crankshaft in the right-hand crankcase half and fit

the crankcase gasket.

– Fit the crankcase screws in the engine base area and tighten them.

– Fit the comparator on the crankcase and measure the crank-

shaft axial play.

Axial play: 0.1 - 0.2 mm

– If the measurement does not correspond to the nominal value,

proceed to rectify the axial play.

– To this end, remove the crankshaft and then remove the inner

collar from the crankshaft on the ignition side using the spe-

cially designed tool. Then add or remove thrust washers as

necessary.

Add thrust washers if the axial play is excessive and re-

move them if the axial play is too small. Thrust washers

can only be added on the ignition side.

1

1

C

2

2

Loading...

Loading...