31

6 - Motore Release 01 Date 09/2007

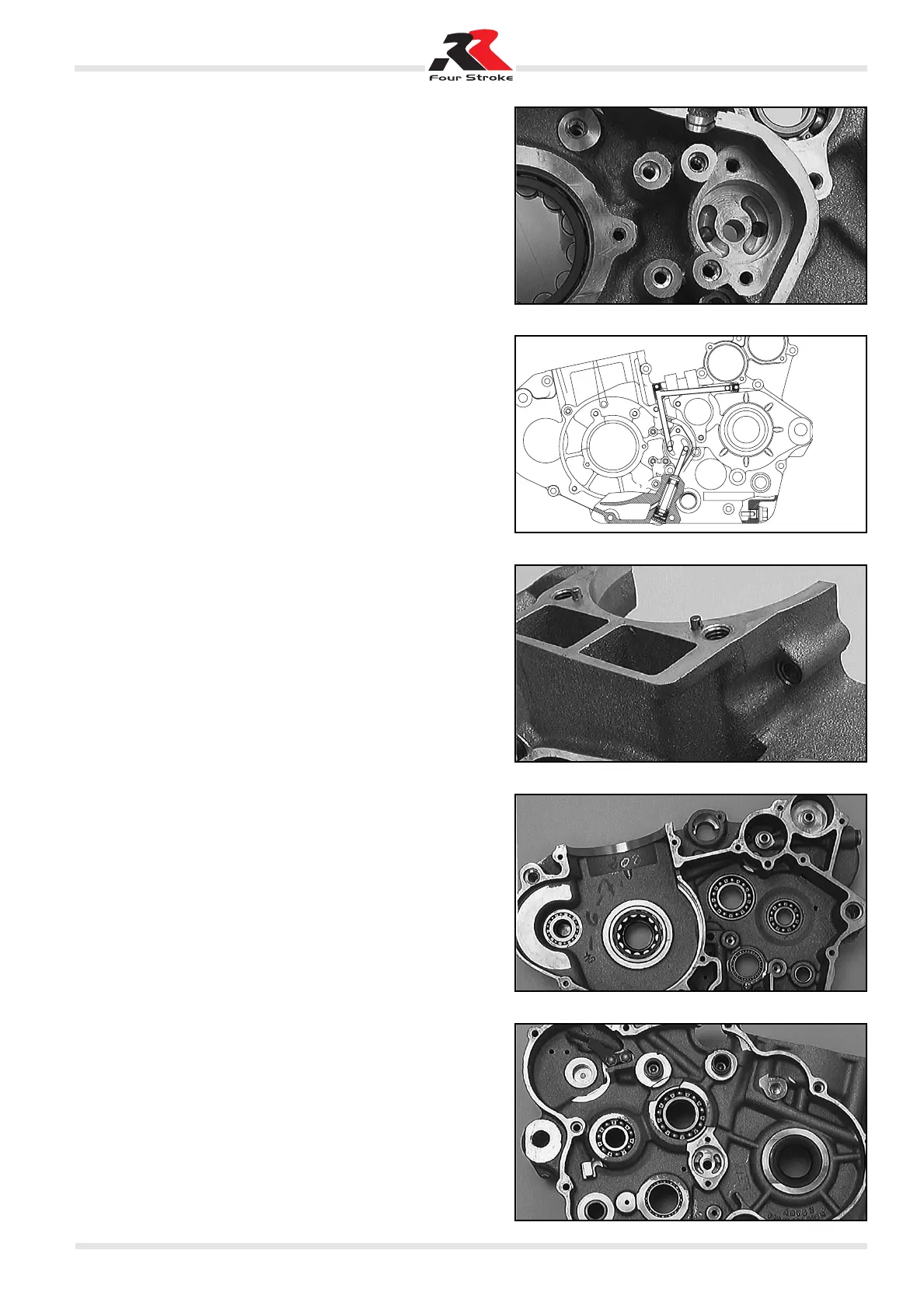

The oil pump casing should show no signs of scoring or seizu-

re.

Blow all the oil channels with compressed air and ensure that

they are clear.

Check that the two steady pins 1 are firmly seated. If necessary

lock with Loctite 243.

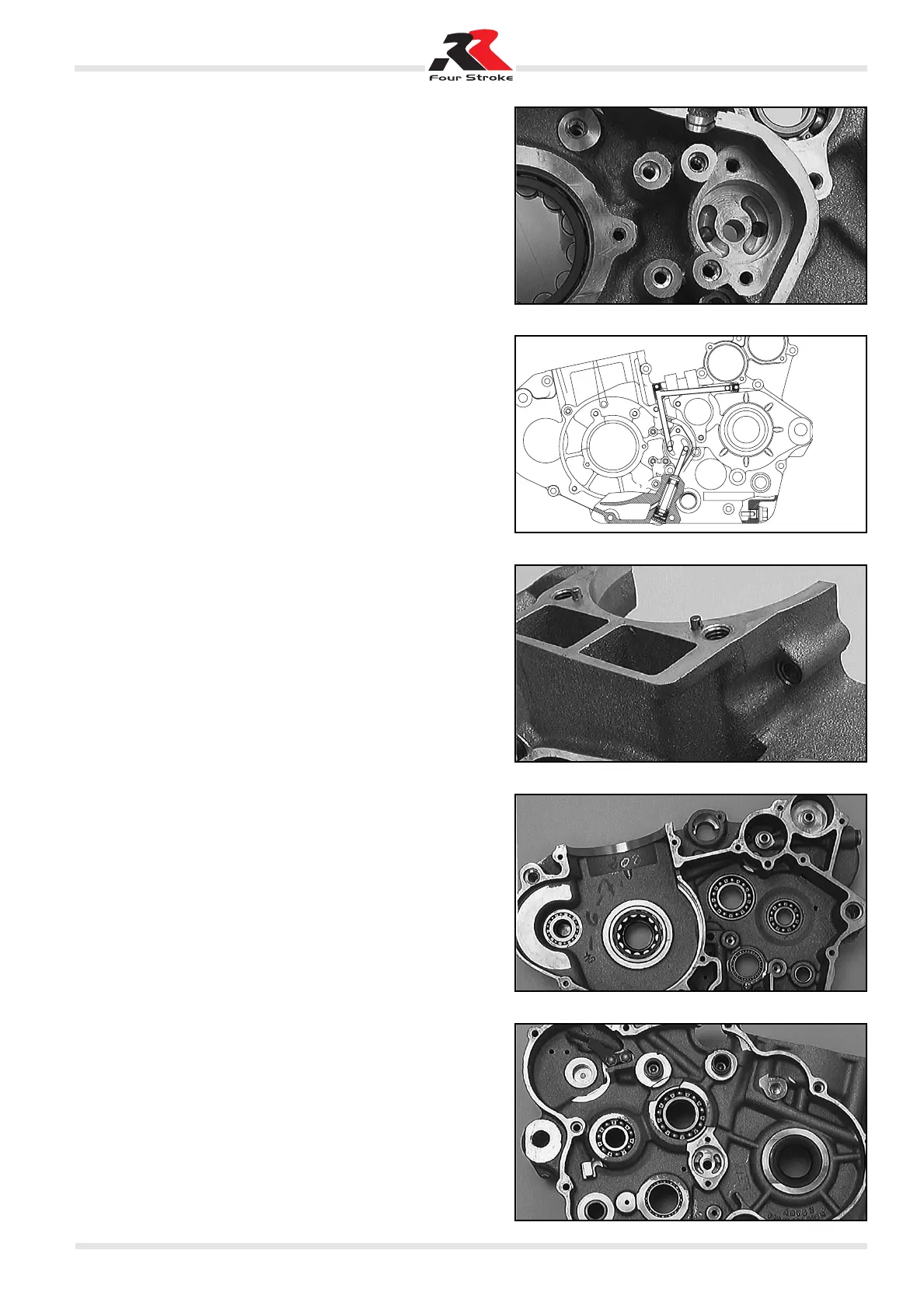

Right-hand crankcase half

Remove all the oil seals and heat the crankcase half in an oven

to a temperature of approximately 150° C.

Crankshaft roller bearing 2

Using a suitable drift, push in the bearing from the outside. Fit

the new bearing, pushing it from the inside to its abutting end.

Driving shaft ball bearing 3

Using a suitable drift, push in the bearing from the outside. Fit

the new bearing, pushing it from the inside to its abutting end.

NOTE: Driving shaft ball bearing 3 is fastened by a screw. Ap-

ply Loctite 243 to the screw thread and tighten to 5 N·m.

Driven shaft ball bearing 4

Using a suitable drift, push in the bearing from the outside. Fit

the new bearing, pushing it from the inside to its abutting end.

Crankshaft oil seal 5

Insert the new oil seal and push it with is open side facing inward

until it is flush.

Kickstart idler gear support pin 6. Electric start idler gear support

pin 7. As a rule, support pins are not subject to wear. Replace-

ment of the support pins should be carefully evaluated, since in

most cases the operation causes damage to the crankcase.

Loading...

Loading...