17

6 - Engine Release 01 Date 09/2007

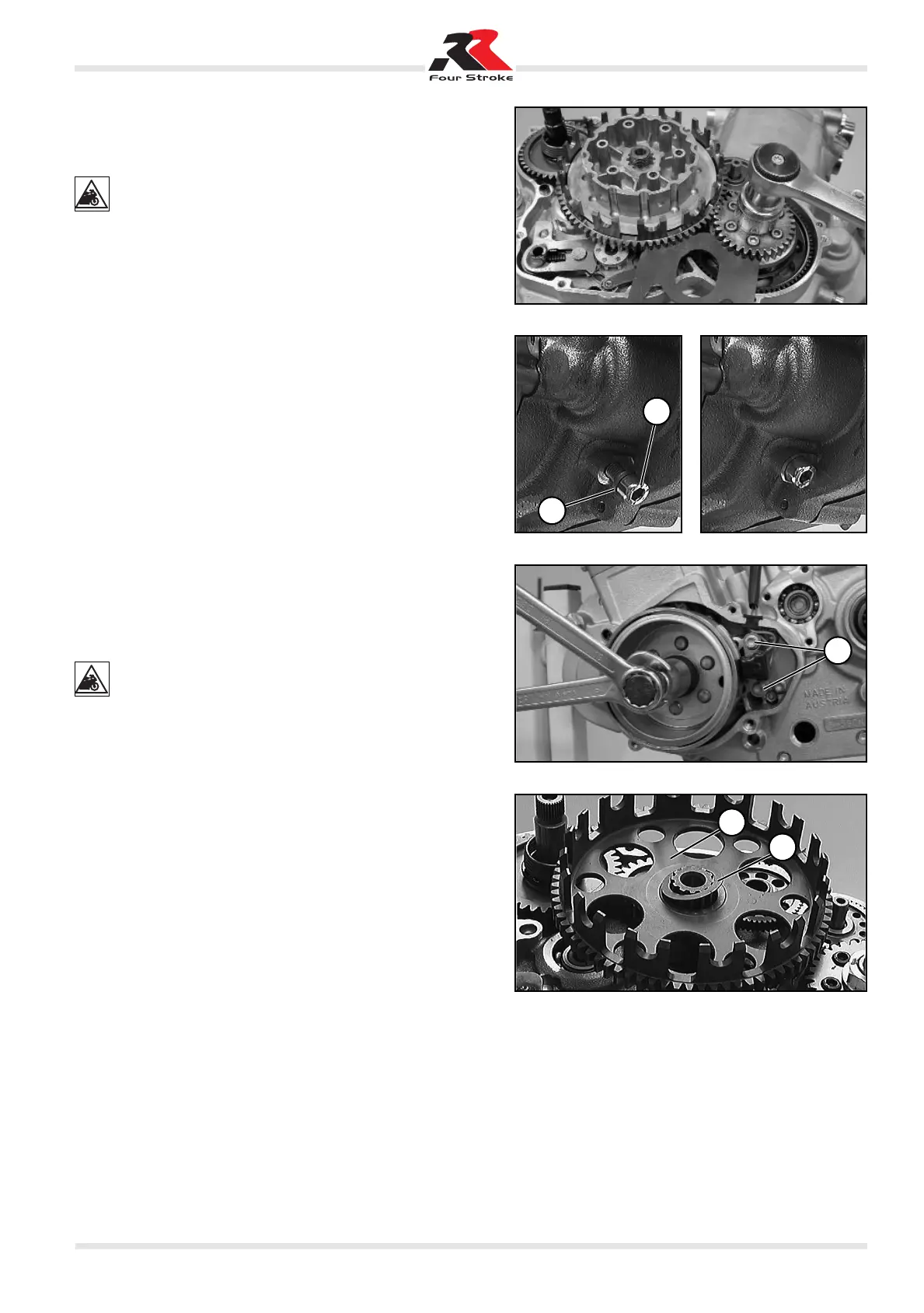

– Position the special tool as shown in the figure, unscrew the

primary torque gear flange nut and remove it.

– Remove the special tool.

THERE ARE FLANGE NUTS WITH LEFT-HAND AND

RIGHT-HAND THREADS. THE FLANGE NUTS BEAR-

ING THE CAPTION “LEFT” HAVE A LEFT-HAND

THREAD. THOSE WITH NO INSCRIPTION HAVE A RIGHT-

HAND THREAD.

– Bring the crankshaft to the top dead centre.

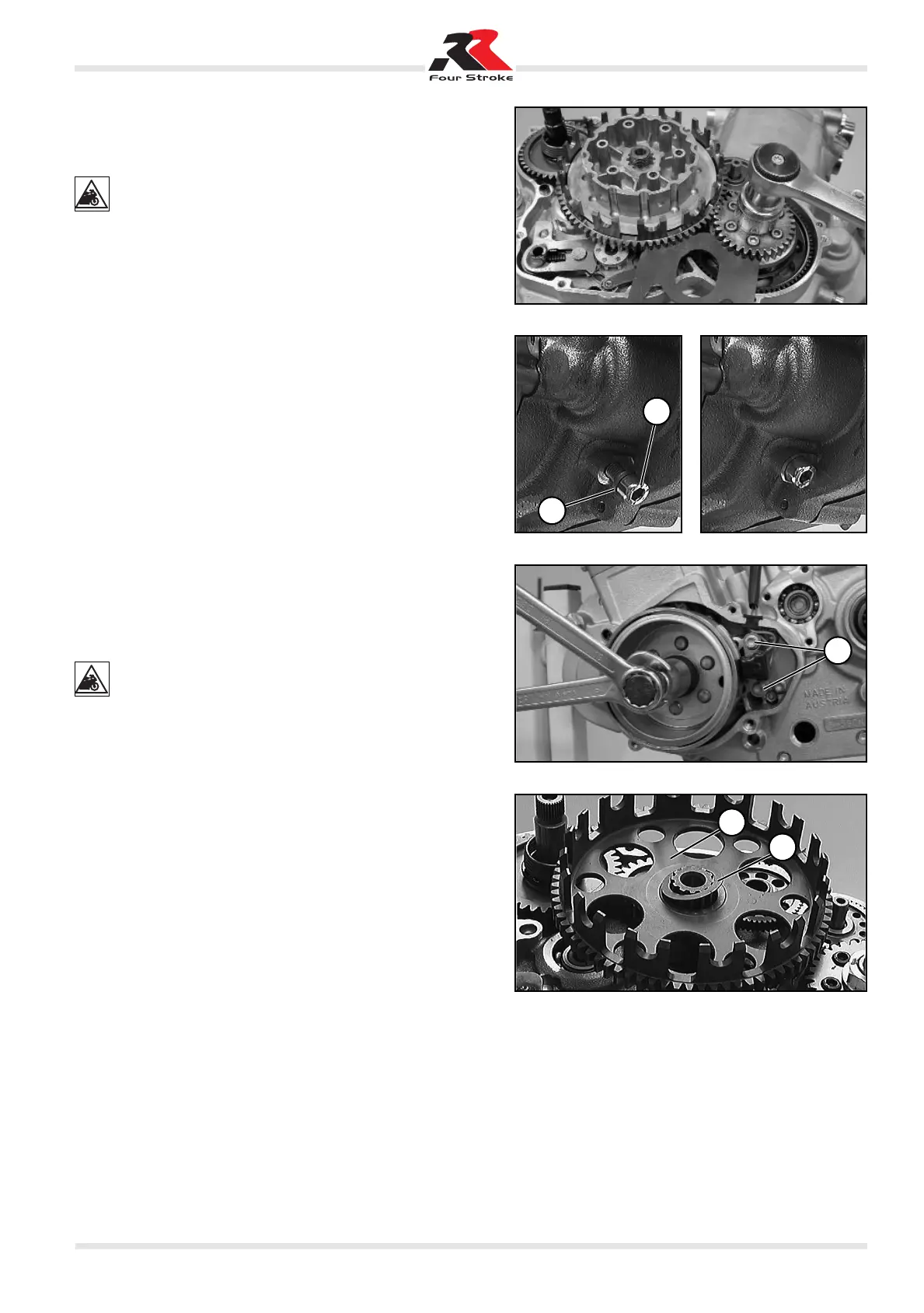

– Unscrew crankshaft fixing screw 1 and remove retaining ring

2.

– Manually screw in the crankshaft fixing screw.

– When resistance is felt, slightly move the flywheel to and fro

until the crankshaft screw is inserted in the related opening in

the crankshaft.

– Tighten the crankshaft fixing screw to 10 N·m.

Pulling out the flywheel

– Unscrew the two screws 3 and remove the pick-up from the

crankcase.

– Fit the puller and pull out the flywheel using the protective cap.

– Remove the key from the crankshaft.

NEVER HIT THE FLYWHEEL WITH A HAMMER OR AN-

OTHER TOOL AS THIS COULD CAUSE THE FLY-

WHEEL MAGNETS TO COME OFF AND DAMAGE THE

CRANKSHAFT. PUSH WITH THE PULLER TO AVOID BEND-

ING THE FIXING SCREW (250 CC MODELS).

Removing the clutch hub and drum

– Fit the protective cap to the driving shaft and then fit the puller.

– Remove the hub from the driving shaft.

– Remove from the driving shaft clutch drum 4 with the support

bush and the two thrust washers.

1

2

3

5

4

Loading...

Loading...