1 689 979 672 2012-06-26| Robert Bosch GmbH

Maintenance | EPS 807 / 815 | 41 en

6. Maintenance

6.1 Cleaning

6.1.1 Calibration fluid, calibration-fluid filter

2

458735/19

! The calibration fluid must not be dirty or mixed with

the lubricating oil from the injection pumps.

i A strong yellow, but clear calibration fluid has been

mixed with lubricating oil; a cloudy grey calibration

fluid is dirty and could damage the injection pumps

and test nozzles.

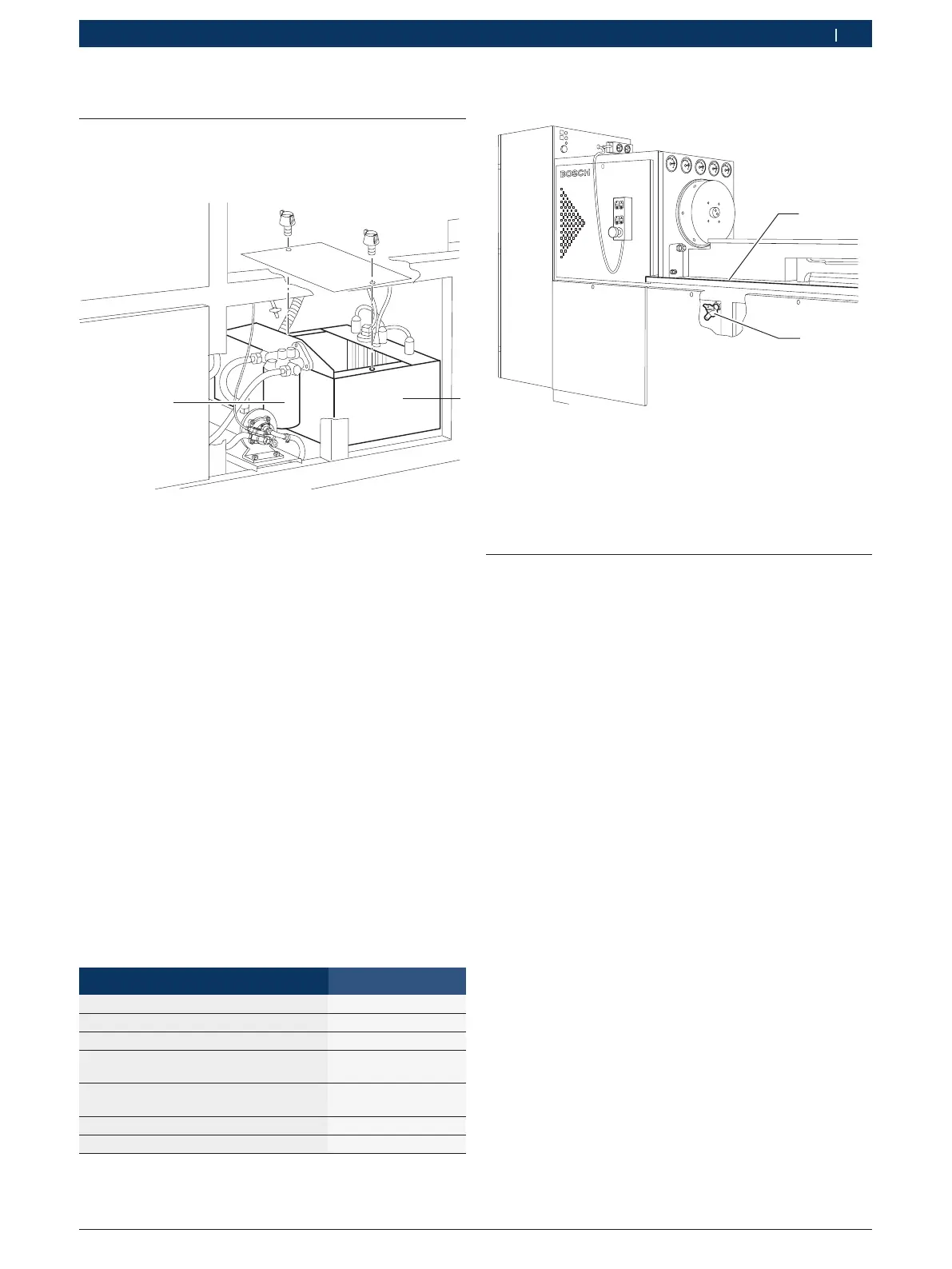

Calibration fluid, calibration-fluid filter (2) must be

changed/replaced:

R After testing 200 injection pumps, however at the

latest every 2 months

R During the main inspection or as required

At the same time clean and rinse the calibration-fluid

tank (1) and suction filter.

The calibration-fluid tank (1) can be drained via the

delivery pump and the pump supply line.

Capacity approx. 50 litres.

Only use calibration fluid pursuant to ISO 4113!

Authorised calibration-fluid grades:

Oil grade Manufacturer

SHELL Calibration Fluid S 9365 Shell International

SHELL V-ÖL 1404 Shell Germany

SHELL Normalfluid B. R. Shell France

VISCOR

Calibration Fluid 1487 AW-2

Rock Vallery

CASTROL

fluido para Calibracao 4113

Castrol Brasilien

ESSO EGL 70 147 Esso AG

BENZ UCF-1 Calibration Fluid Benz Oil

i See Chapter 7 "Decommissioning".

6.1.2 Contaminated oil

1

2

458735/20

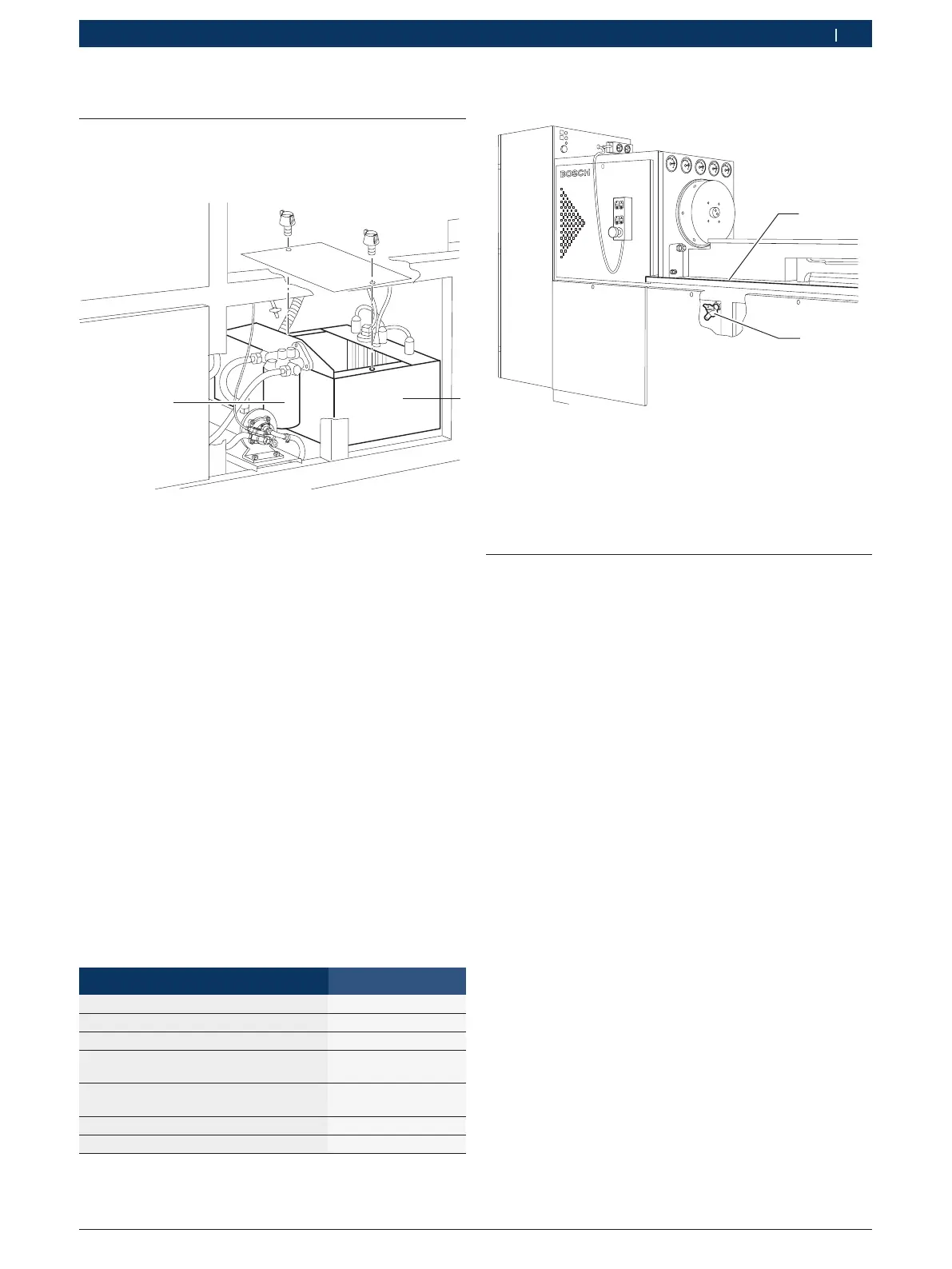

The contaminated oil must be drained weekly, or as

required, in the storage area (1) under the mounting

rail. Place a suitable container under the drainage tap

(2) and drain the contaminated oil.

i See Chapter 7 "Decommissioning" regarding disposal.

6.2 Maintenance

The EPS, like any industrial device, requires proper

maintenance at regular intervals.

The maintenance intervals refer to the operation of the

EPSin vehicle service centres for 8 hours per day. Reduce

the intervals accordingly if the operating time is extended.

The portable tester 0986614000 is recommended

when carrying out maintenance work (available through

AA/SWS1). The portable tester contains all the calibrat-

ed measuring instruments and accessories required for

a maintenance check.

The test service (checking the measuring accuracy) is

also performed by the Bosch After-Sales Service using

flow rate normals.

See subsequent sections in this Chapter regarding

capacities, oil grades and other maintenance information.

Loading...

Loading...