PART 7 COMPONENTS

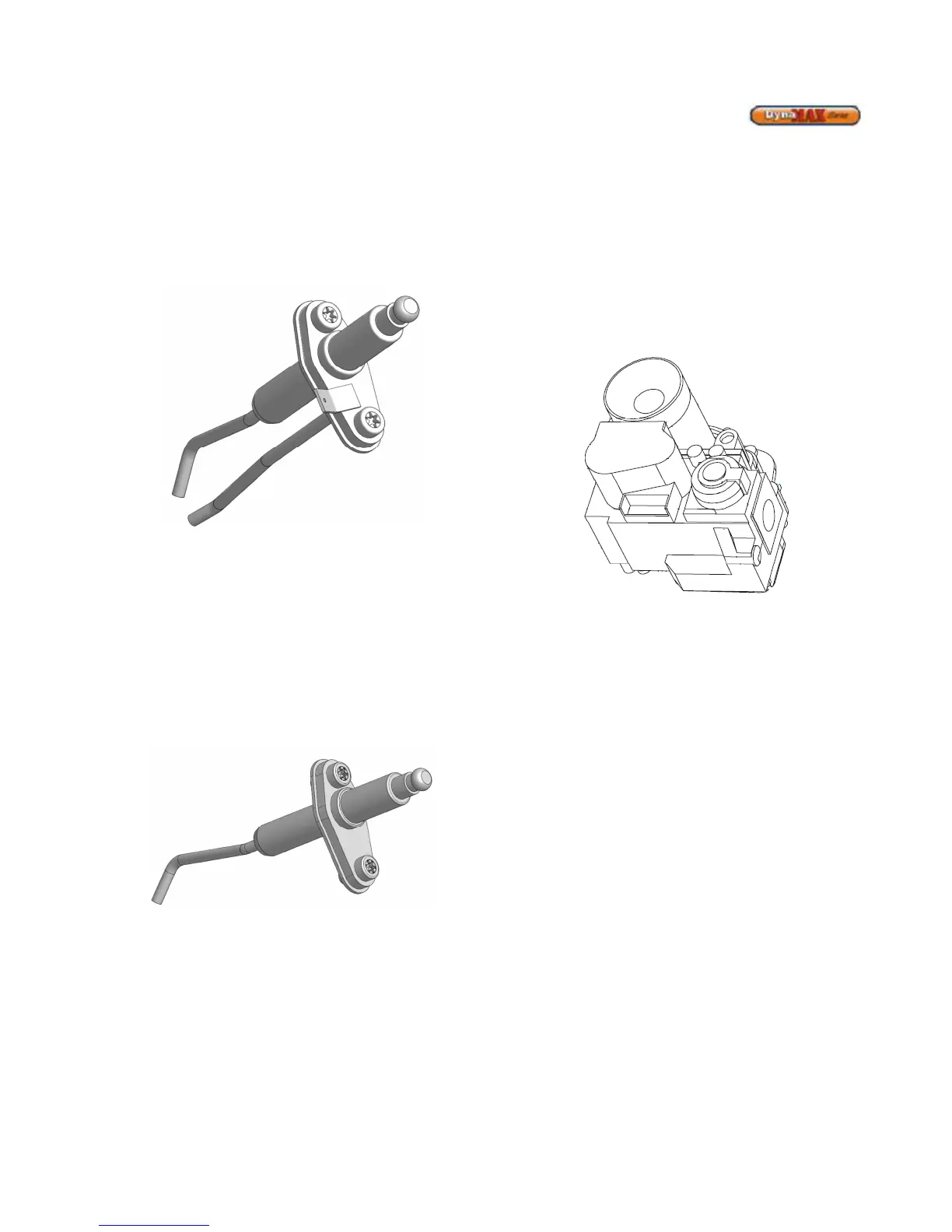

7.1 DIRECT SPARK IGNITER

The direct spark igniter is inserted directly through the

combustion chamber front door and held in place by two

torx-20 screws. Care must be taken when removing and/or

installing the igniter. Always remove the igniter prior to

removing the fan assembly for inspection of the burner and

heat exchanger.

Figure 23: Direct Spark Igniter

During a trial for ignition sequence a properly operating

igniter will generate a continuous spark with a 9/64” (3.6mm)

spark gap. It is recommended to clean the direct spark

igniter using steel wool as required. DO NOT use sandpaper

or grit-cloth since this will contaminate the metal surface.

7.2

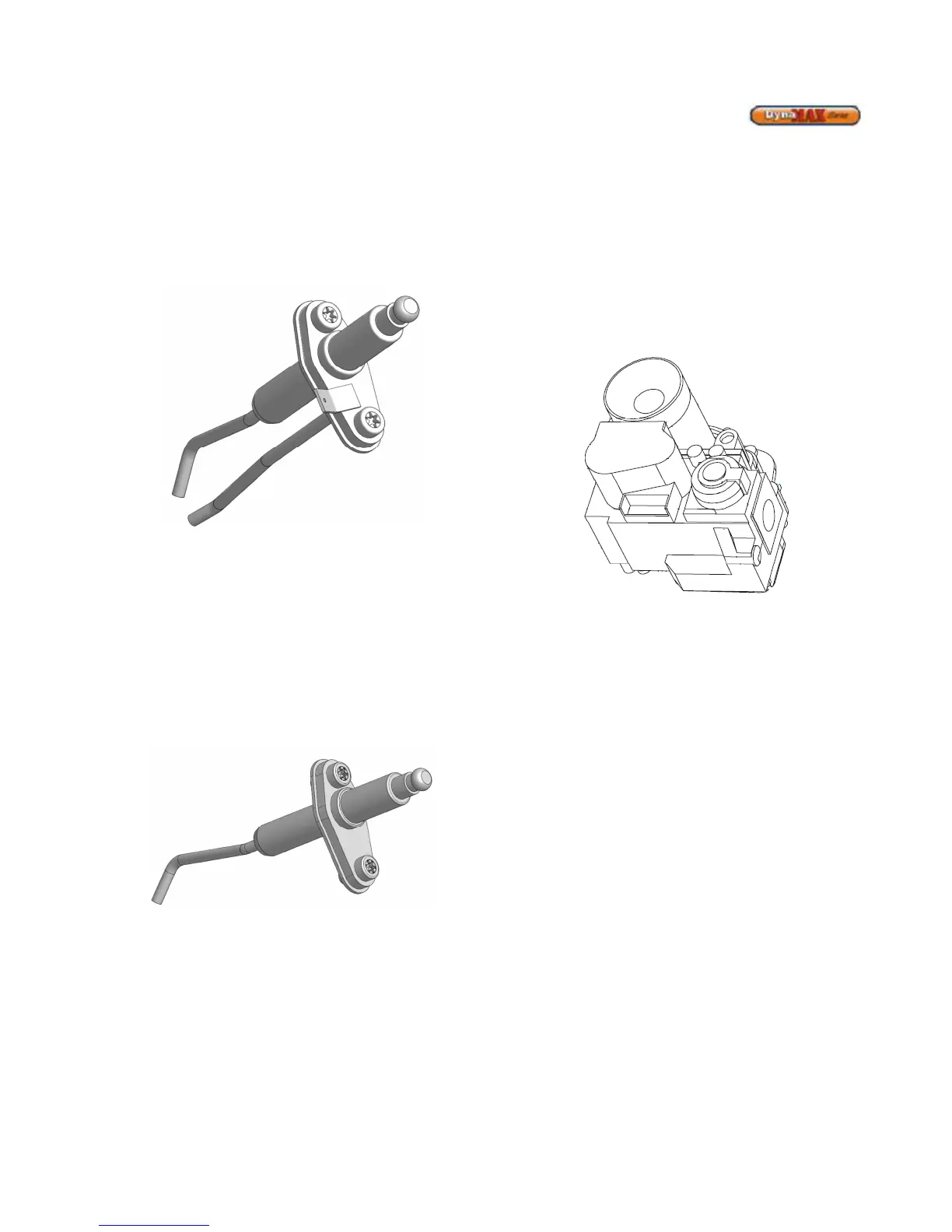

FLAME SENSOR

The flame sensor is inserted directly through the combustion

chamber front door and is screwed into the combustion

chamber front door by torx-20 screws. Care must be taken,

when installing the flame sensor, to align it perpendicular to

the fan flange and parallel to the burner tube and not to over

tighten.

Figure 24: Flame Sensor

The ignition module relies on the flame sensor to provide a

flame rectification signal. Oxide deposits, improper

placement or damaged ceramic insulator will result in

insufficient signal leading to ignition module lock out. For

proper operation minimum 1.25 µA DC must be fed back to

the module. Oxide deposit on the sensor rod must be

removed with steel-wool. DO NOT use sand-paper or grit-

cloth since this will contaminate the metal surface.

7.3 COMBUSTION AIR FAN

DynaMax uses a modulating air fan to provide combustible

air/gas mix to the burner and push the products of

combustion through the heat exchanger and venting system.

The fan assembly consists of a sealed housing and fan

wheel constructed from spark resistant cast aluminum. The

fan is operated by a fully enclosed 120 VAC, Single-Phase

EC/DC electric motor. The fan housing and motor assembly

is fully sealed and SHOULD NOT be field serviced. The

power draw of the motor is proportional to the modulated gas

input rate of the appliance.

7.4 GAS VALVE

Figure 25: Venturi and Gas Valve Arrangement

The Gas Valve supplied with the DynaMax boiler is a

combined valve/venturi assembly. A servo pressure

regulator is incorporated into the gas valve to provide stable

gas supply. Pressure taps are provided to check inlet and

outlet gas pressures. An internal fine mesh screen is

incorporated in the inlet of the gas valve to prevent debris

from entering the combustion chamber. Gas valves are

factory set at low and high fire and modulates to maintain

combustion characteristics across the full operating range.

7.5 OUTER JACKET

The outer jacket assembly is constructed from mirror finish

stainless steel. This ensures a long life for the jacket

assembly, with full integrity

Loading...

Loading...