12.15 Alarm Output (if equipped)

This is a feature that is offered on the 848IF. An alarm output

is available to signal was sensed in the connected heating

system. Once an alarm is signalled by the alarm output it

can be reset by means of the External Reset Input.

The alarm output is a normally open, dry contact/ potential

free output. If an error is sensed in one of the attached

boilers the Alarm output contact closes. The output can be

used to drive an external device such as a lamp, a buzzer, a

PLC or a building management system. Refer to 15.3 848IF

Interface Module Wiring Schematic for complete wiring

details.

The IF code scans its Modbus holding registers (0x0000,

0x0010...0x0090) for a STATE that is not equal to zero. If a

state not equal to 0 (zero) is found the IF subsequently

checks for an ERROR_NUMBER not equal to 0xFF to see if

this device is in error. If so, the alarm relay is energized and

the alarm output contact closes.

The alarm output functionality can be used even if Modbus

communication is non-existent.

Due to communication latency it can take several minutes for

the Alarm output to reflect the state of any of the connected

boilers. Especially in a cascade system and/or when

LabVision is connected.

12.16 External Reset (if equipped)

The external reset can be controlled by a relay or

pushbutton.

If the input is open the resetting of an error is an enabled.

Once an error is signalled by the alarm output it can be reset

by shorting the external reset input to 0V. A reset command

is then sent over to the DynaMax Ignition Module and the

external reset is disabled until the input is open again. Refer

to 15.3 848IF Interface Module Wiring Schematic for

complete wiring details.

12.17 0-10Vdc External Input (if equipped)

An analog input can be used to control the CH or the DHW

set point. The input can handle input voltages of up to

10Vdc. A resistor of 500Ω may be added to obtain a 0-

10Vdc input from a 4-20mA signal. Refer to 15.3 848IF

Interface Module Wiring Schematic for complete wiring

details.

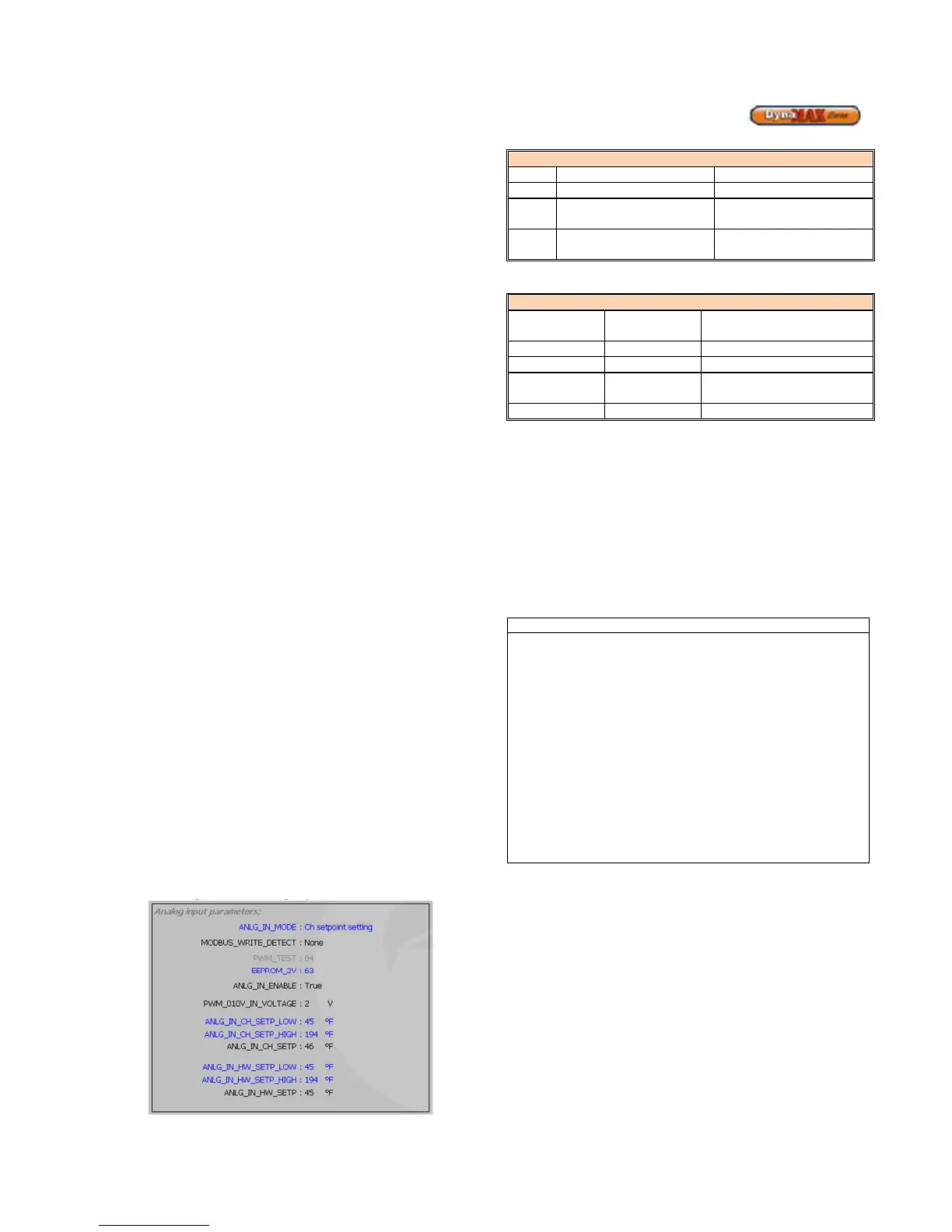

The analog input setting screen is shown below in

LabVision:

Figure 68: Analog Input Parameters

Table 42: Analog Input Selection

F

The ANLG_IN_ENABLE parameter determines whether the

analog input is enabled or disabled. The ANLG_IN_ENABLE

parameter is set to ‘False’, analog input is disabled, under

the following circumstances

• When the ANLG_IN_MODE is set to 0 (off)

• When the input voltage is less than 2V

• From the moment a Modbus write command is

detected until 4.25 minutes after the last Modbus

write command was ended. Modbus set point

setting has priority over the Analog input set point

setting

• During commissioning (and when altering the

ANLG_IN_MODE setting) the setpoint that is not

controlled by the analog (or Modbus) must be checked/

set manually after setting the mode

• If the Analog input is not connected (open) the default

input voltage is 2.5V. If the analog input is not to be

used it must be disabled by setting ANLG_IN_MODE to

0.

• The analog input and Modbus connection can be used

simultaneously but when the Modbus connection is

used to set the setpoint the analog input is disabled.

• In a cascade system only the setpoints of the MN board

connected directly to the IF board can be controlled.

12.18 APPLIANCE

∗ Remove manometers and tighten test port screws.

∗ Fill out start up report for each heater. Be sure to record

all settings and readings. Retain a copy of report for

future reference.

∗ Start up is now complete and heater may be placed into

service.

Loading...

Loading...