DHW Priority

When both a CH demand and DHW demand exist

simultaneously, DHW will always have priority. When DHW

demand ends the boiler will check the Outlet Temperature

sensor or System Sensor and Room Thermostat switch to

determine if CH demand exists.

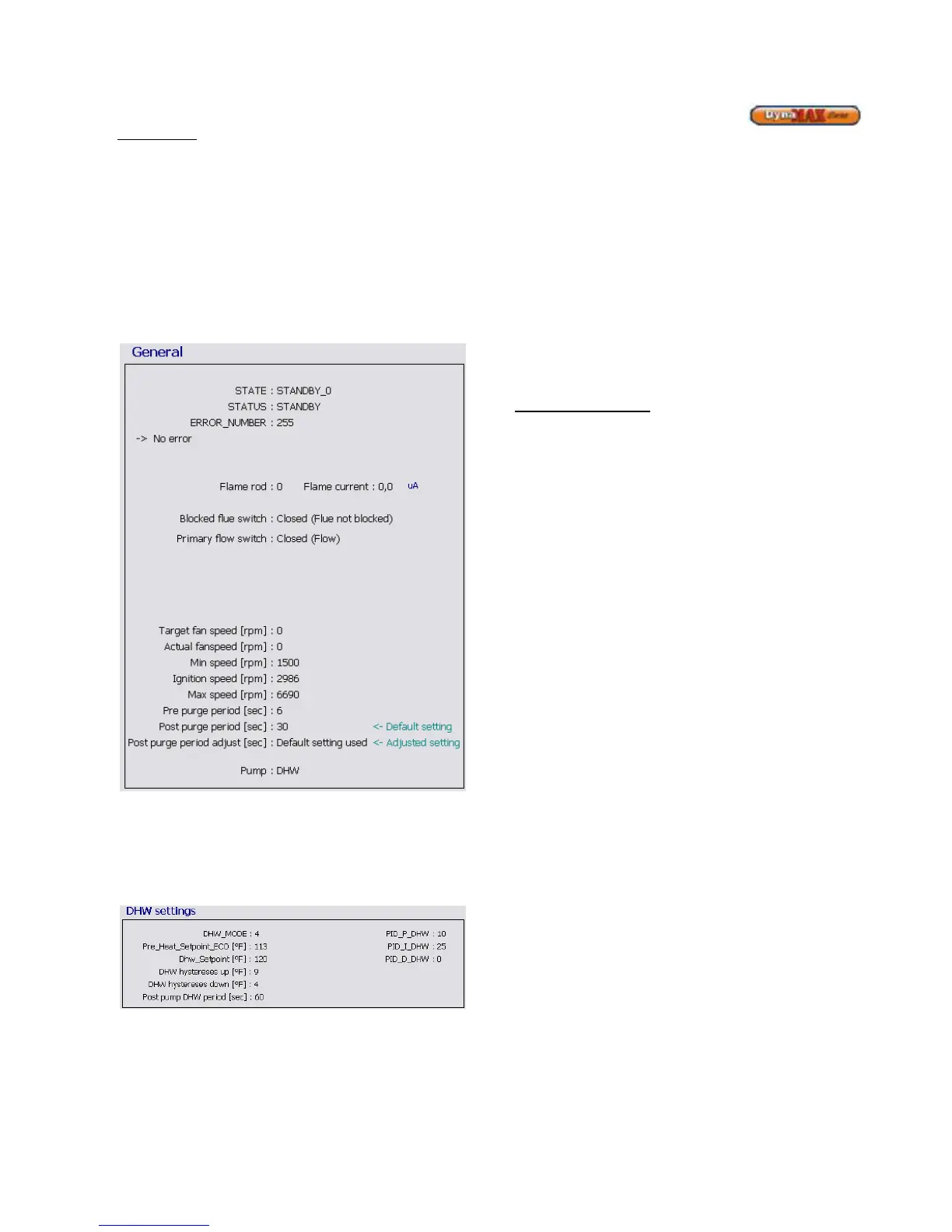

Flame rod current in µA can be observed. Fan speeds

cannot be altered here, instead they are varied under the

Settings screen. This is covered in Section 8.2 of this

manual The Maximum Stack Setpoint Temperature and the

Flue Diff. Temperature cannot be changed to preserve

reliable and efficient performance.

Figure 43: DHW Mode 4 General Screen

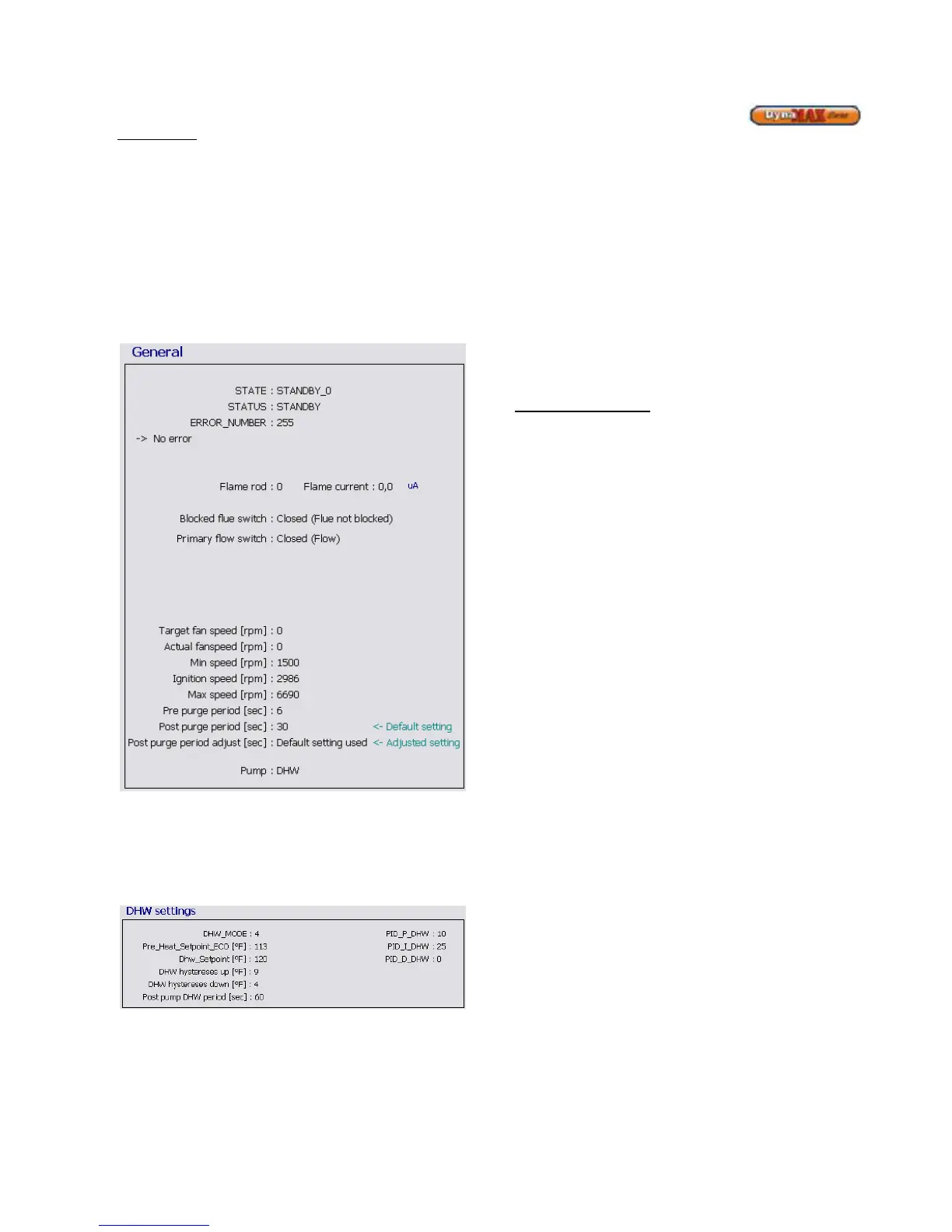

To change a blue coloured parameter, place the cursor over

a parameter and double-click. This will bring up a window to

enter the desired values of operation. Take note of the

minimum and maximum values that can be entered, as the

values entered MUST be within this range

Figure 44: DHW Mode = 4 Settings

8.7 LABVISION CASCADE

When connected in a cascade setup the Master boiler can

control up to 7 slave boilers (ie. a total of 8 boilers) from the

control panel of the Master Boiler. All control operation can

be performed on the Master boiler, which can then relay the

relevant information to the slave boilers. Therefore a direct

connection to the Master Boiler and LabVision is required for

communication using LabVision.

When the master boiler detects a heat demand for CH this

boiler will start and uses it own parameters for CH demand.

If after cascade_delay_time the system temperature is still

below the set point the next boiler will start.

When the master temperature (T_system) plus

cascade_hyst is greater than the set point a boiler will be

stopped. If after a period of cascade_delay_time this

situation is still present the next boiler is switched off.

Sequence of Operation:

When a boiler is set as MASTER (address =1), the controller

of this boiler will drive the cascade. THE CH mode of the

master boiler is applicable for the total cascade system.

• The outdoor temperature sensor connected to the

MASTER will be the outdoor sensor for the cascade

system

• The system temperature sensor connected to the

MASTER will be the control sensor for the cascade

supply temperature.

• The thermostat connected to the MASTER will be

the CH heat demand input for the cascade system.

When demand for CH present the first boiler will start and

uses its own parameters for CH demand. After a period of

CC_TIME the MASTER compared the system temperature

with the cascade set point and will check if:

1) An additional boiler is needed

T_system < CH set point – cc_hyst

2) Number of boilers remain the same

T_system > CH_setpoint – cc_hyst AND

T_system < CH set point + cc_hyst

3) A boiler should stop.

T_system > CH_setpoint + cc_hyst

Loading...

Loading...