12.14 Write Functionality

The DynaMax Ignition module may be only reset when it is in

error. Only manual reset errors can be reset by writing

0x4000 to the Reset & R/W control holding register (0x001A)

of the Modbus interface (this sets the MN reset bit of the

Reset & R/W control holding register) The 848IF then sends

a reset command to the DynaMax Ignition Module over the

established link.

The Reset & R/W control register of the MN (0x001A) also

controls the reading and writing of the DynaMax Ignition

Module holding registers. Each bit of the Reset & R/W

control register corresponds with one parameter of the

Read/Write holding registers table. When a bit in the Reset &

R/W control is clear the data in the corresponding holding

register byte is fetched from the DynaMax Ignition Module

into the 848IF. When a bit in the Reset & R/W control

register is set the data in the corresponding holding register

byte is sent from the IF to the MN. To set an RC parameter

through Modbus first set its bit in the Reset & R/W control

register. This stops the parameter being fetched from the

MN. Then write the desired value into the parameters

holding register. The following table lists the Reset & R/W

control bits and corresponding parameters.

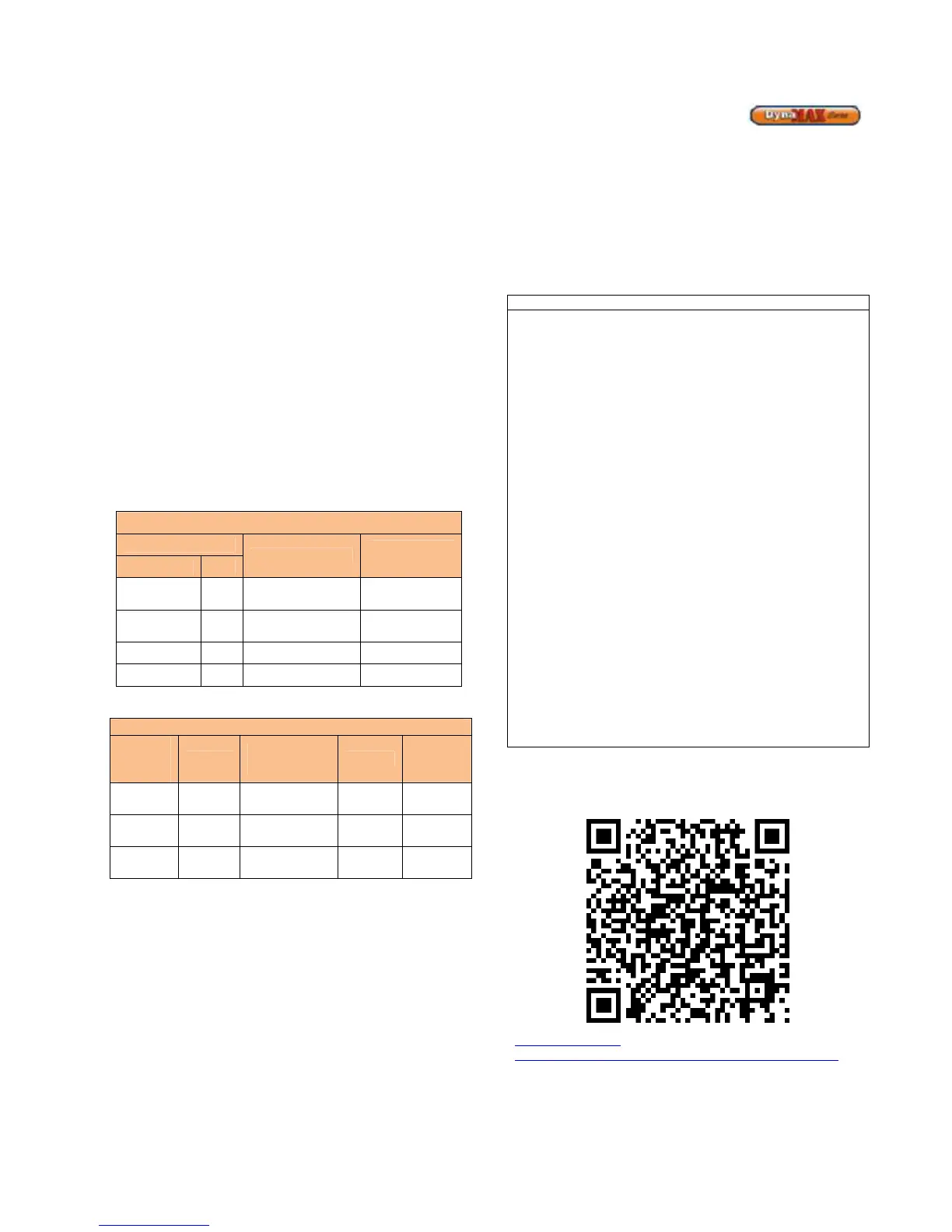

Table 40: Modbus Read/Write Registers

Read/Write Holding Registers

Item Index

Parameter Name

Holding

Registers

Word Byte

Control 0x001A

14 High Byte 14 CH_Setpoint 0x001E

14 Low Byte 15 DHW_Setpoint 0x001E

Table 41: Modbus Control Bits

R/W

control

register

bit

MN_Parameter

Name

Byte

Holding

Register

Low byte

1 CH_Setpoint 14

High byte

14 MN Reset bit

12.14.1 Write CH Setpoint

1) Issue a Modbus write single holding register

command writing 0x0002 to the Reset & R/W

control register located at 0x001A to switch from

CH set point reading to writing

2) Calculate the scaled set point = (((x-

32)/1.8)+10)*2*256

3) Issue a Modbus write single holding register

command writing the scaled calculated set point to

the 0x001E holding register

12.14.2 Write DHW Setpoint

1) Issue a Modbus write single holding register

command writing 0x001 to the Reset & R/W Control

register located at 0x001A to switch from DHW set

point reading to writing

2) Calculate the scaled set point = ((x-32)/1.8)+10)*2

3) Issue a Modbus write single holding register

command writing the scaled and calculated set

point to the 0x001E holding register

• Be advised that whenever the MN control is reset, it will

revert back to the setpoints stored in the E2Prom. After

every MN reset (automatic, through Modbus, via the IF

External Reset Input or via the RC reset button) the

Modbus controller must make sure that the error

condition has been resolved (ERROR_NUMBER =

0xFF) and then re-write the desired setpoints through

Modbus

• If the Reset & R/W control register bit of a setpoint is

set, the setpoint in the IF is communicated with the MN

as long as it differs from the setpoint in the DynaMax

Ignition Module. If the setpoint is then changed by

means of the Display or LabVision it will again be

different from the setpoint in the IF and thus, again be

overwritten by the setpoint in the IF. As long as the

Reset & R/W control register bit of the setpoint is set the

IF overrules all other setpoint settings. Clear the bit in

the Reset & R/W Control register to re-enable setting of

the setpoint by RC or LabVision

• When no Modbus communication (reading or writing) is

sensed for more than 4.25 seconds the R/W control

register bits will be reset. The R/W control register bits

will be reset. The R/W control register bits will also be

reset when undefined bits (ie. other than bits 0 and 1)

are set.

• In a cascade system only the setpoints of the MN board

connected directly to the IF board can be controlled.

For additional information for interfacing the boiler with

Modbus/Bacnet/LonWorks:

http://www.camus-

hydronics.com/Downloads/DynaMax_Protocol_Setup.pdf

Loading...

Loading...