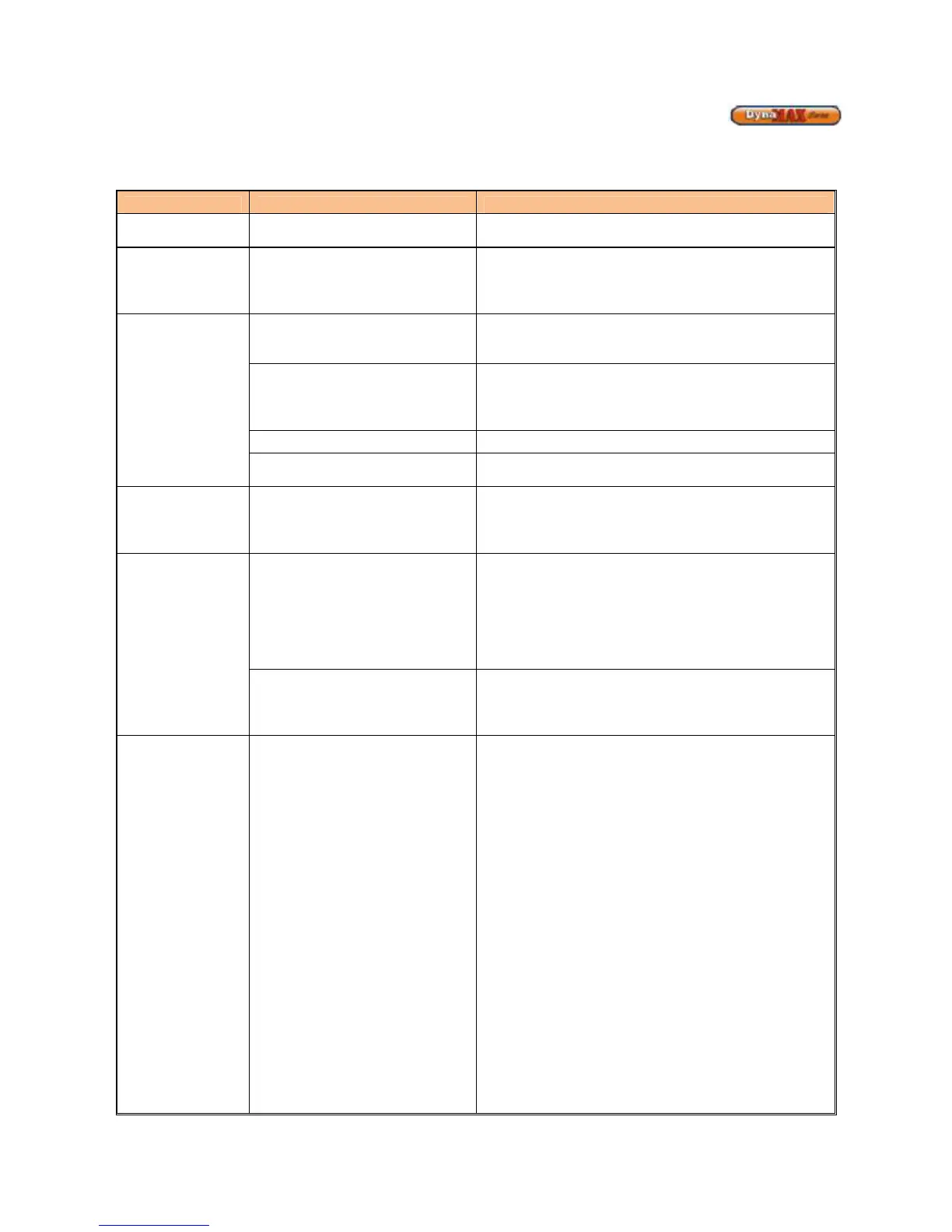

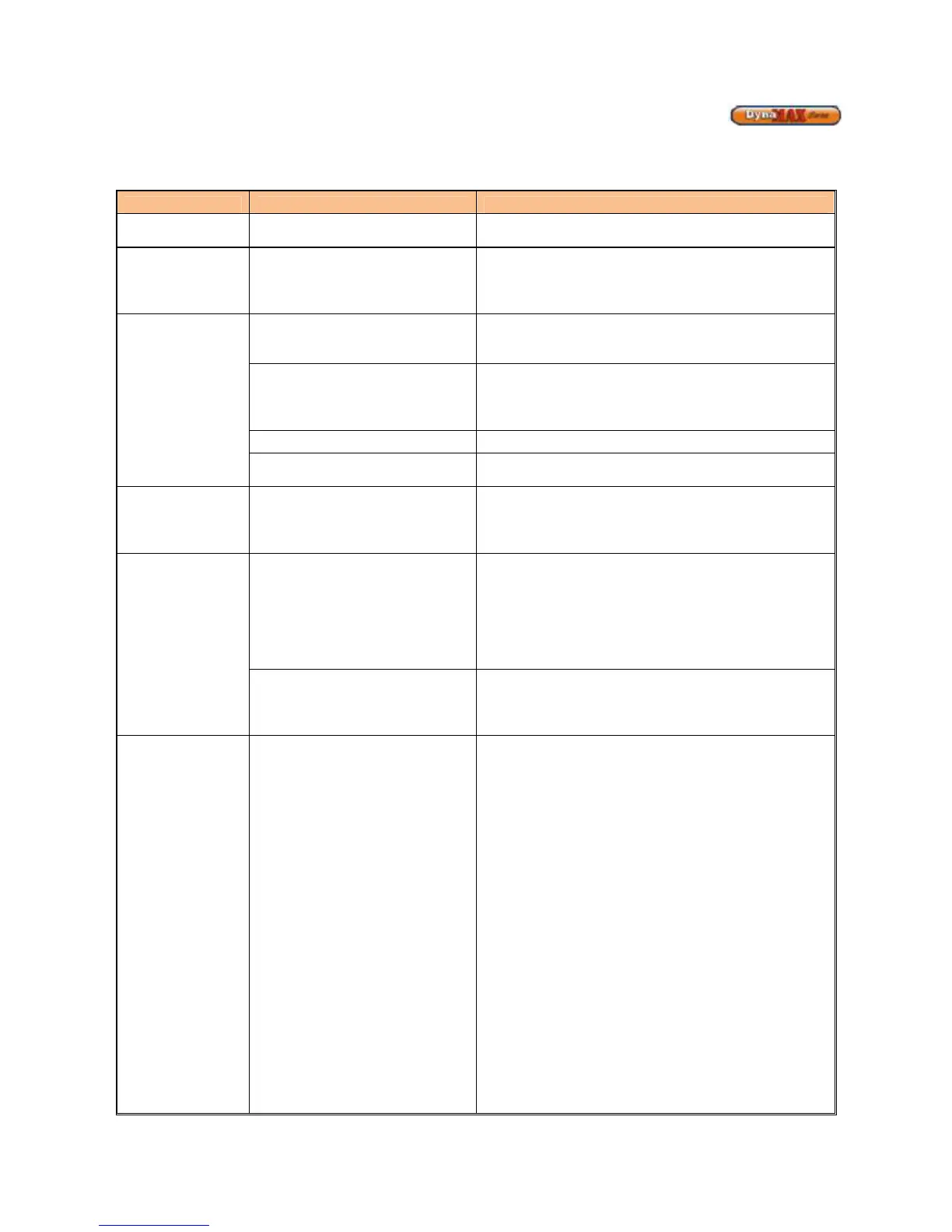

PART 10 TROUBLESHOOTING

Table 29: Troubleshooting Table

COMPONENT FAILURE MODE ANALYSIS

Incoming Power

• Two wires interchanged • No effect on safety

• Live and Neutral wires are interchanged.

Transformer

Tripped

• The 24Volts and 120 Volts

wired are interchanged

• Transformer immediately burns out, replace

transformer

• Fuse on DynaMax Controller blows, replace 3.15A

fuse located at F1 on DynaMax Controller.

Pump Fails to

Circulate

• Wiring Issue • Check that wires are correctly wired from the

DynaMax Controller to the pump delay relay.

• Check that 115V is delivered to pump coil.

• Faulty Pump on a wet rotor

pump

• Pump impeller may be stuck. Use a flat head

screwdriver on face of pump to turn impeller

manually

• Replace Pump

• Air in the piping system

• Purge all air from the piping system

• Internal Fault on DynaMax

Controller

• Replace DynaMax Controller

Relief Valve

• System pressure exceeds relief

valve setting

• Replace the standard relief valve with a higher rated

valve up to the maximum pressure of the heat

exchanger.

• Improperly sized expansion tank.

Flow Proving

Device/ LWCO

• Flow Proving Device/ LWCO

contacts are open

• Verify LED’s on current sensing transformer during a

heat demand (wall hung)

• Check flow switch paddle (floor mount)

• Verify for closed valves or obstructions in boiler

piping

• Verify that all air has been purged from the system

• Verify that wiring is correct

• Blown Fuse • Replace 3.15A Fuse located at F1 on DynaMax

Controller.

• DO NOT use alternates as it may damage the

DynaMax Controller

Loading...

Loading...