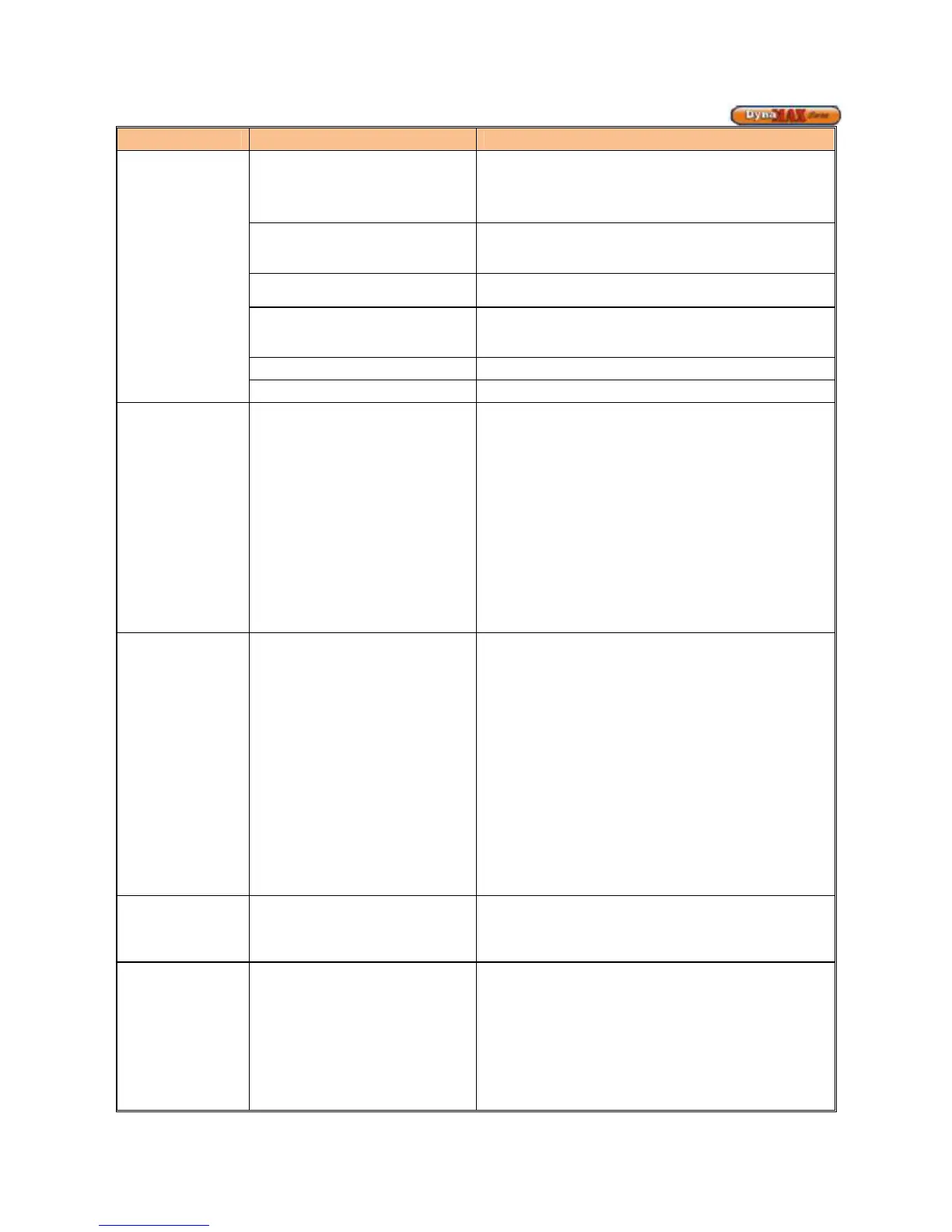

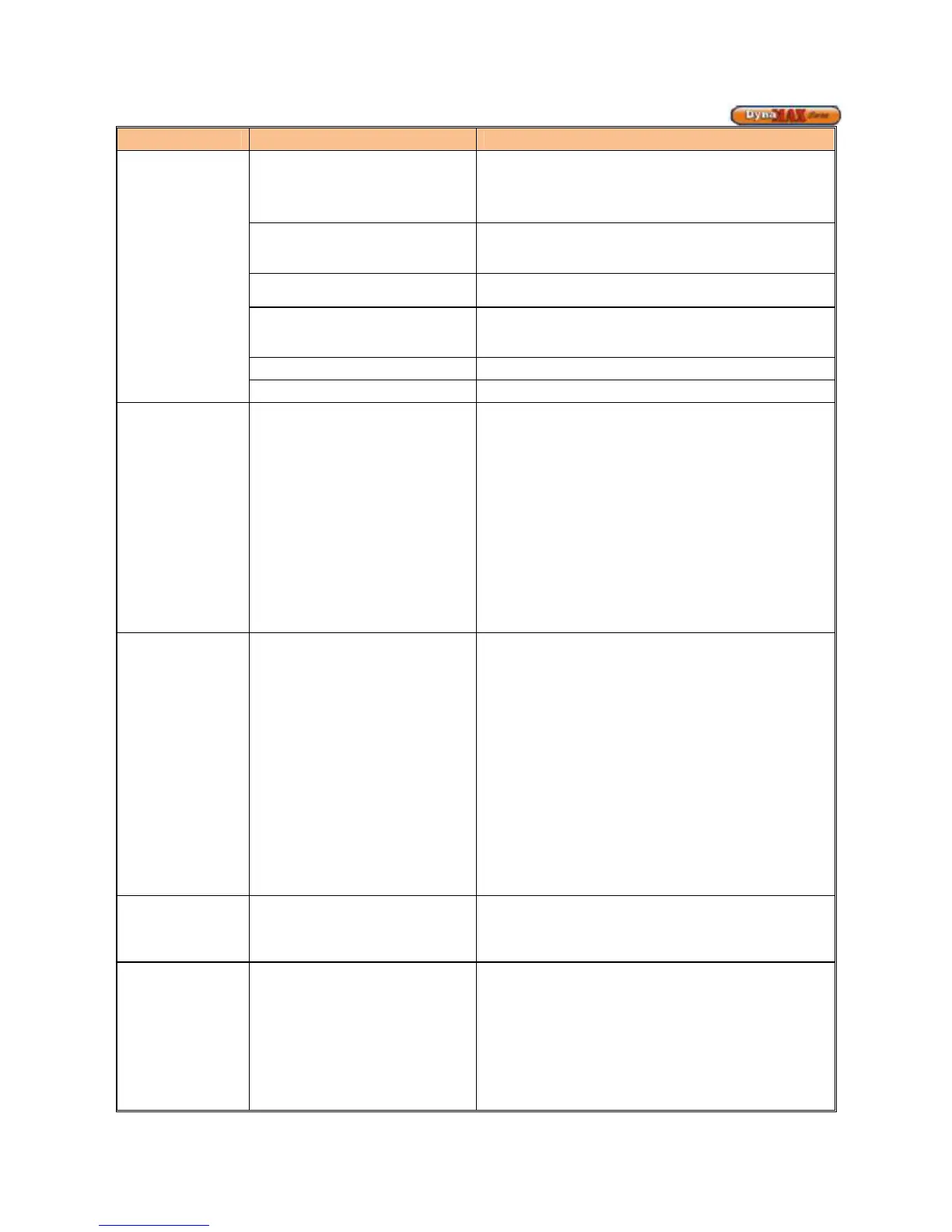

SYMPTOM FAILURE MODE ANALYSIS

Noisy Operation

• Supply Gas Issue

• Refer to Part 3 Gas Connection in this manual.

• Natural Gas Pressure should read between 3” w.c.

and 14” w.c.

• L.P. Gas Pressure should be at 11” w.c.

• Air/Gas Mixture Issue • Refer to Gas Valve Adjustment Procedure in section

10.2 of this manual for the proper combustion

setting.

• Air Inlet and/or Vent

configuration

• Refer to Part 2 Air Inlet and Venting

• Dirty/ Damaged burner • Refer to Burner Maintenance in section 11.7 of this

manual for the burner removal and inspection

procedure. Clean or replace the burner, if required.

• Air in the piping system

• Purge all air from the piping system

• Incorrect igniter gap

• Check that spark gap is 9/64”

Auto Reset High

Limit Trips

• The supply/ outlet temperature

has exceeded 210

o

F.

• Verify that the system is full of water and that all air

has been properly purged from the system.

• Verify that the boiler is piped properly. Refer to

Piping Diagrams in Section 13 of this manual.

• Verify that 120VAC is being supplied to the boiler

pump on a call for heat. If voltage cannot be

detected check wiring.

• Verify that the pump is circulating when 120VAC is

detected. If not, pump impeller may be stuck. Use a

flat head screwdriver on face of pump to turn

impeller manually

• If 120VAC is present during a call for heat, but the

pump still does not circulate, replace the pump.

• Replace the main DynaMax Controller if necessary

Manual Reset

High Limit Trips

(Pressing the

manual RESET

on the DynaMax

Control Panel will

be required to

restart the ignition

sequence)

• Manual Reset Safety High Limit

tripped, supply/outlet

temperature in excess of 210

o

F

• Verify that the capillary tube is broken. If this is the

case, replace Manual Reset High Limit

• Verify that the system is full of water and that all air

has been properly purged from the system.

• Verify that the boiler is piped properly. Refer to

Piping Diagrams in Section 13 of this manual.

• Verify that 120 VAC is being supplied to the boiler

pump on a call for heat. If voltage cannot be

detected check wiring.

• Verify that the pump is circulating when 120 VAC is

supplied. If so, pump impeller may be stuck. Use a

flat head screwdriver on face of pump to turn

impeller manually.

• If 120 VAC is present during a call for heat, but the

pump still does not circulate, replace pump.

Fan Speed Too

Low

• Actual fan RPM is 30% slower

than target fan speed.

• Verify wiring connections at the fan and DynaMax

Controller.

• Replace the fan

• Replace the DynaMax Controller.

Fan Speed Too

High

• Actual fan RPM is 30% faster

than what is required.

• Vent/ Air Inlet Lengths exceed the maximum allowed

equivalent lengths. Refer to Air Inlet and Venting

Section in Part 2 of this manual.

• Verify that there are no obstructions in the vent/ air

inlet pipes or at terminations

• Verify wiring connections at the fan and DynaMax

Controller.

• Replace the fan

• Replace the DynaMax Controller.

Loading...

Loading...