Flue Gas Error displayed on screen

A flue gas error occurs when the stack temperature has exceeded the maximum limit allowed by the vent material. This is an

automatic reset error, when the stack temperature drops 20

o

F below the limit allowed the boiler is allowed to restart and an ignition

attempt is made if the call for heat is not yet satisfied. In the event that a setpoint greater than 150

o

F is selected and PVC venting is

used the setpoint must be reduced to below 150

o

F to avoid nuisance flame failures. If a setpoint greater than 150

o

F is required,

venting with CPVC, AL29-4C, 316LL or PPE is strongly advised.

The stack temperature is between 10-150

o

F above the incoming (return) water temperature to the appliance.

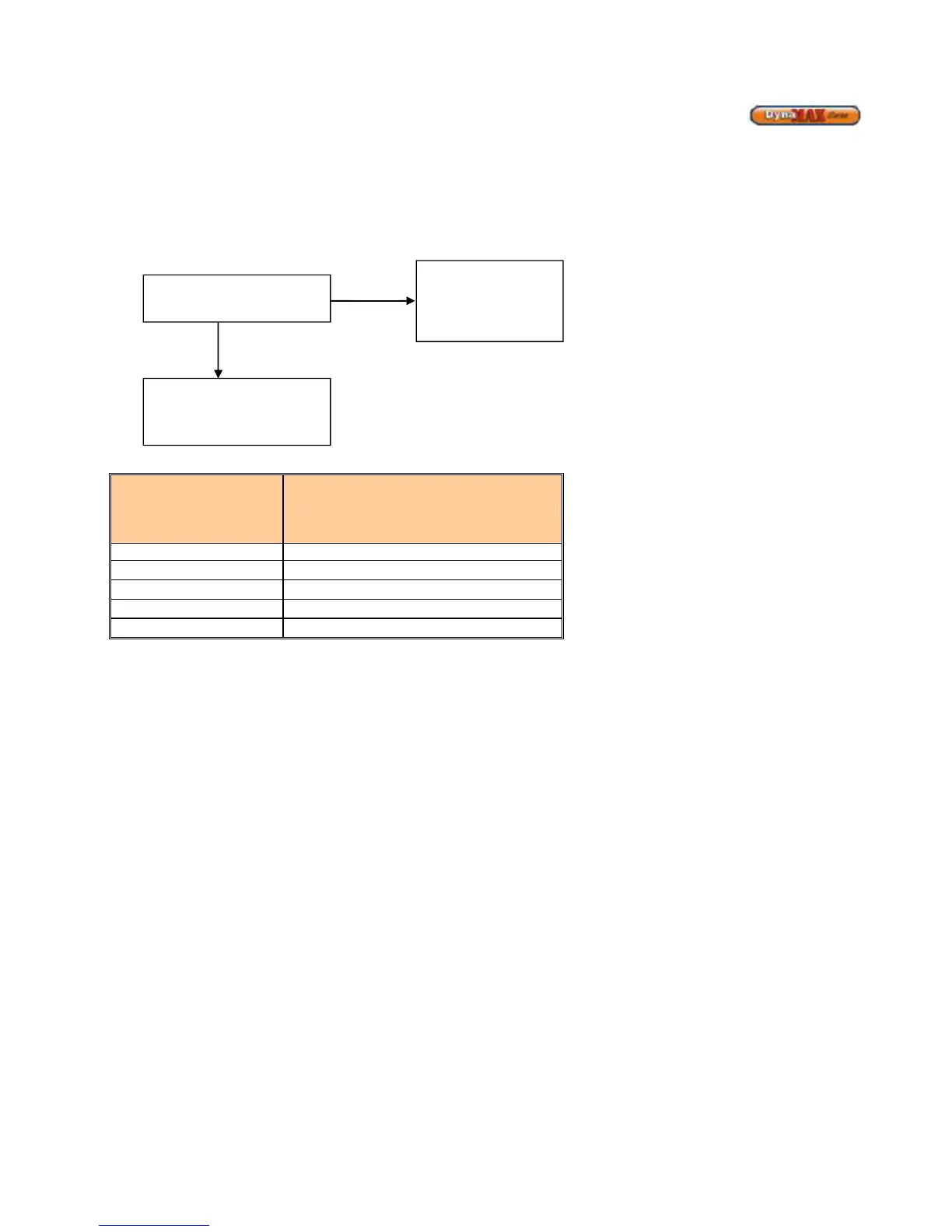

Vent Material Maximum Flue Temperature [

o

F]

149

CPVC

194

PPE

230

AL29-4C

300+, limited only by rating of seals

316L Stainless Steel

300+, limited only by rating of seals

NOTE: Depending on the required setpoint the conversion from a PVC limited appliance to a CPVC, PPE, AL29-4C or Stainless

steel vented appliance may require the replacement of the PVC high limit (TCL085A) as it is designed to trip at 180

o

F outlet water

temperature whereas the CPVC high limit (TCL110A) is designed to trip at 210

o

F.

Is vent material PVC plastic?

(white in colour)

YES

Adjust CH and/or

DHW Setpoint to

150

o

F or less to avoid

nuisance trips

NO

Select the correct vent

material setting through

LabVision or boiler display

Loading...

Loading...