Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 115 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

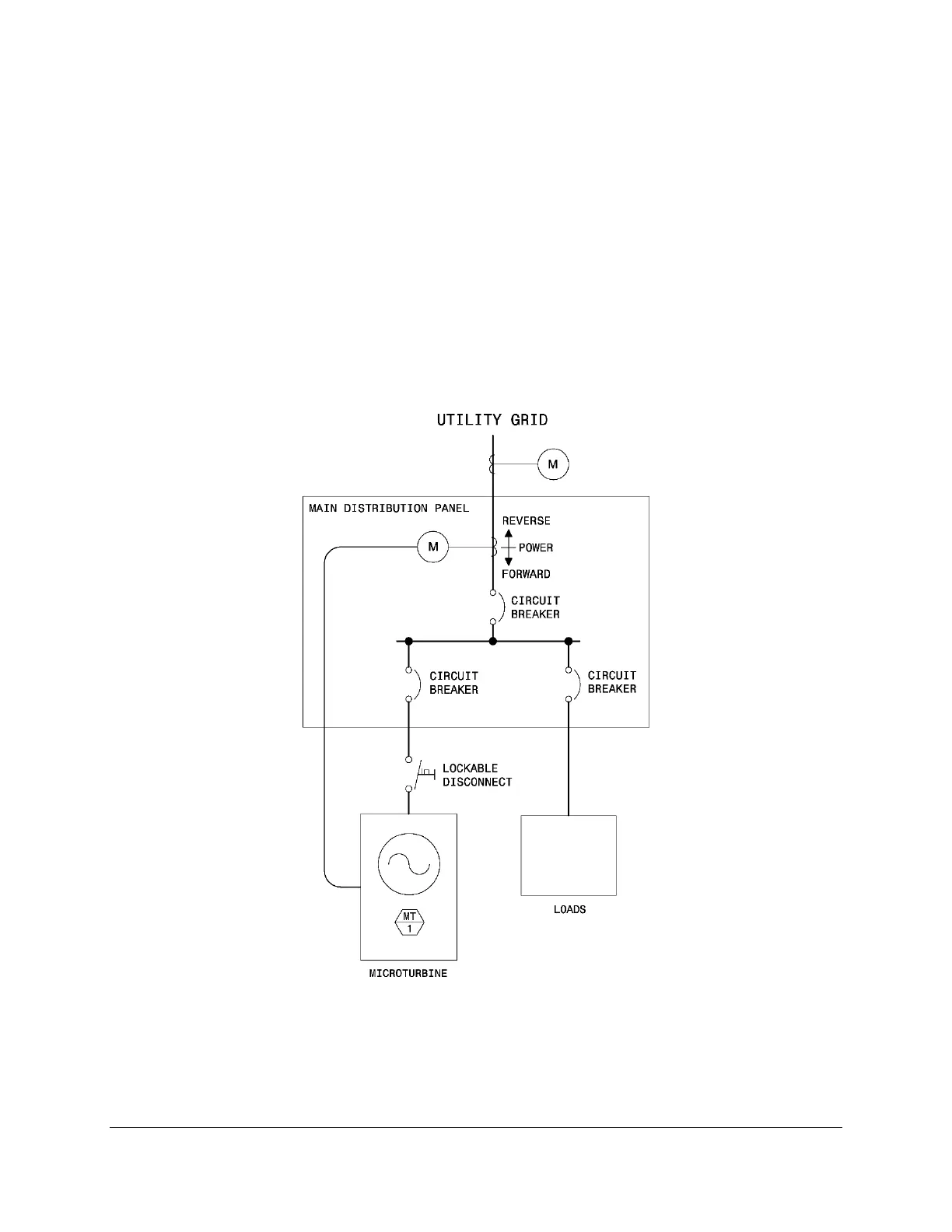

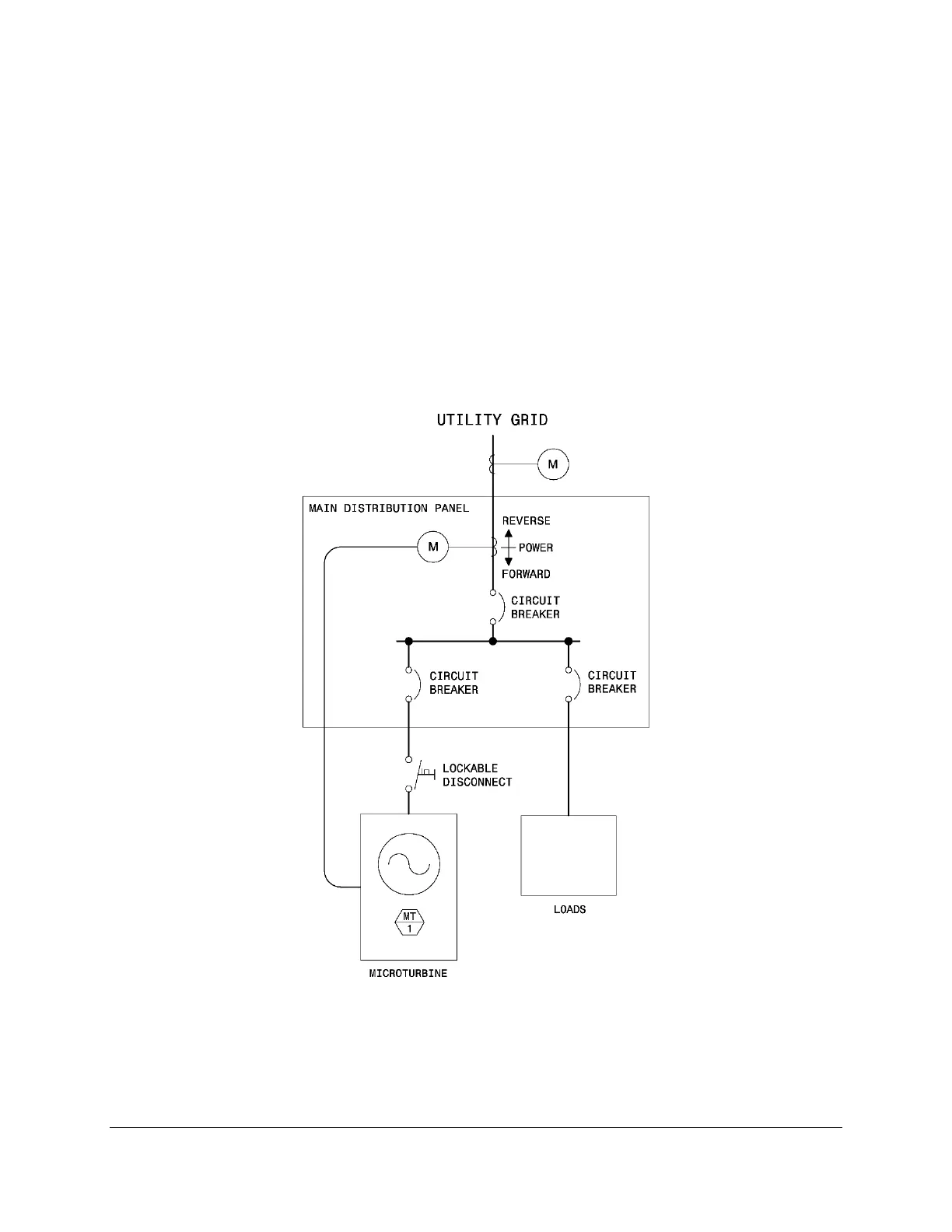

8.2.4.1. Power Meter Applications

In Grid Connect applications with variable electric loads, a utility may restrict power exporting.

These restrictions can be adhered to using non-power export mode or limited power export mode.

The microturbine can accommodate pulse inputs for forward power flow (+PWR) and reverse

power flow (-PWR) signals at a rate proportional to the power flow to control power produced.

The microturbine ramps power output up and down, keeping the required power level at the

control point.

Consideration should be given to meters approved by the utility company for compatibility, when

used at the PCC or any other point controlled by the utility, especially if used as a revenue meter

for accounting purposes.

The C1000 series controller is designed to accept signals from a Modbus slave power meter using

RS-485 wired to the PLC. See Figure 58 for Modbus slave connections (TB1-60, TB1-61, TB1-62)

in the C1000 series controller, and Figure 59 for a typical power meter installation.

Figure 59. Typical Power Meter Installation

Loading...

Loading...