Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 49 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

5.4.1.2. Outdoor Installations

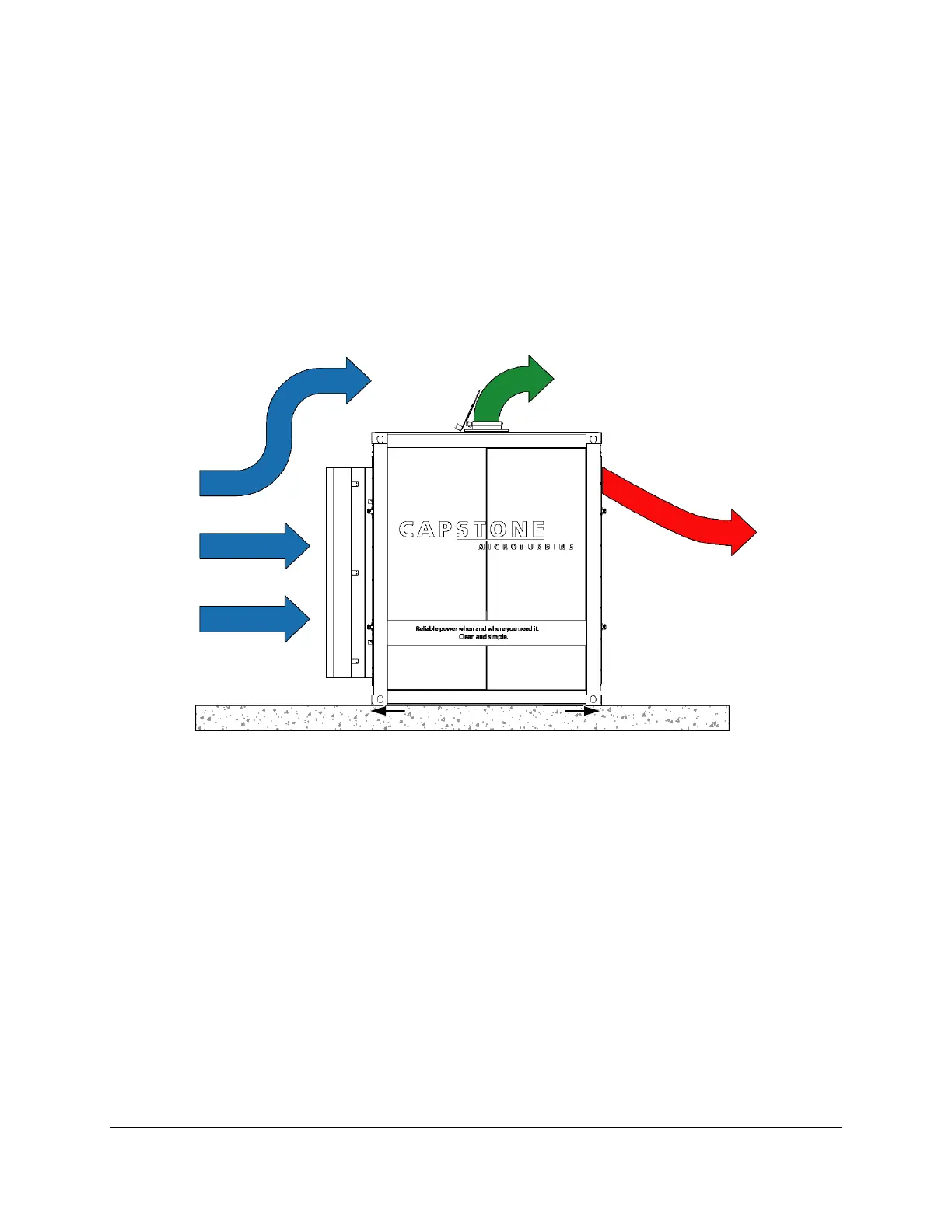

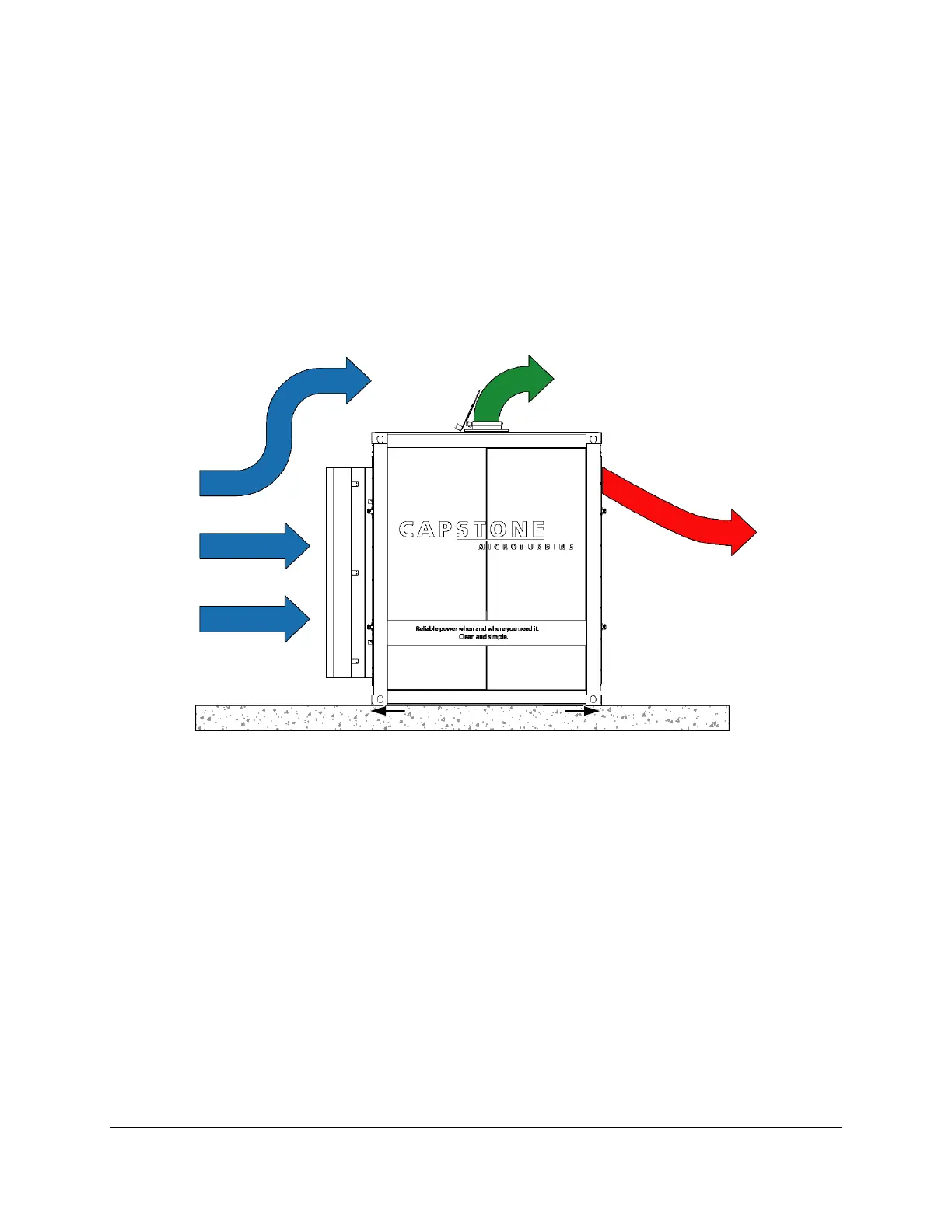

Install the microturbine in a manner such that prevailing winds will carry engine exhaust

away from the air intake. See Figure 22.

The microturbine should be located away from polluted atmosphere acidic fumes,

digester contaminated air, all forms of dust (e.g. cement dust, stone dust, etc.), cotton

fibers, furnace chemicals, etc., whenever possible.

It is recommended that a wall be constructed to protect the microturbine from wind-borne

contaminants.

Figure 22. Orientation to Prevailing Winds

5.4.1.3. Extreme Cold Environment Installations

For extreme cold applications (less than 20 °C/-4 °F), unit(s) must be installed in a closed room

and adhere to recommendations listed in Indoor Installations (paragraph 5.4.1.1).

To maintain proper room temperature, install temperature-controlled louvers.

Room heating may be needed to maintain the required inlet temperature limits.

Black-start considerations: Microturbines may experience cold soak in temperatures

below the low limit. Catalytic heaters can use the pressurized microturbine fuel to heat

the room and microturbine before the engine starts.

Consider installing a separation wall with louvered or removable sections to allow

recirculation of hot air to the inlet side of the microturbine when ambient temperatures

are colder in the microturbine room.

Loading...

Loading...