Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 54 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

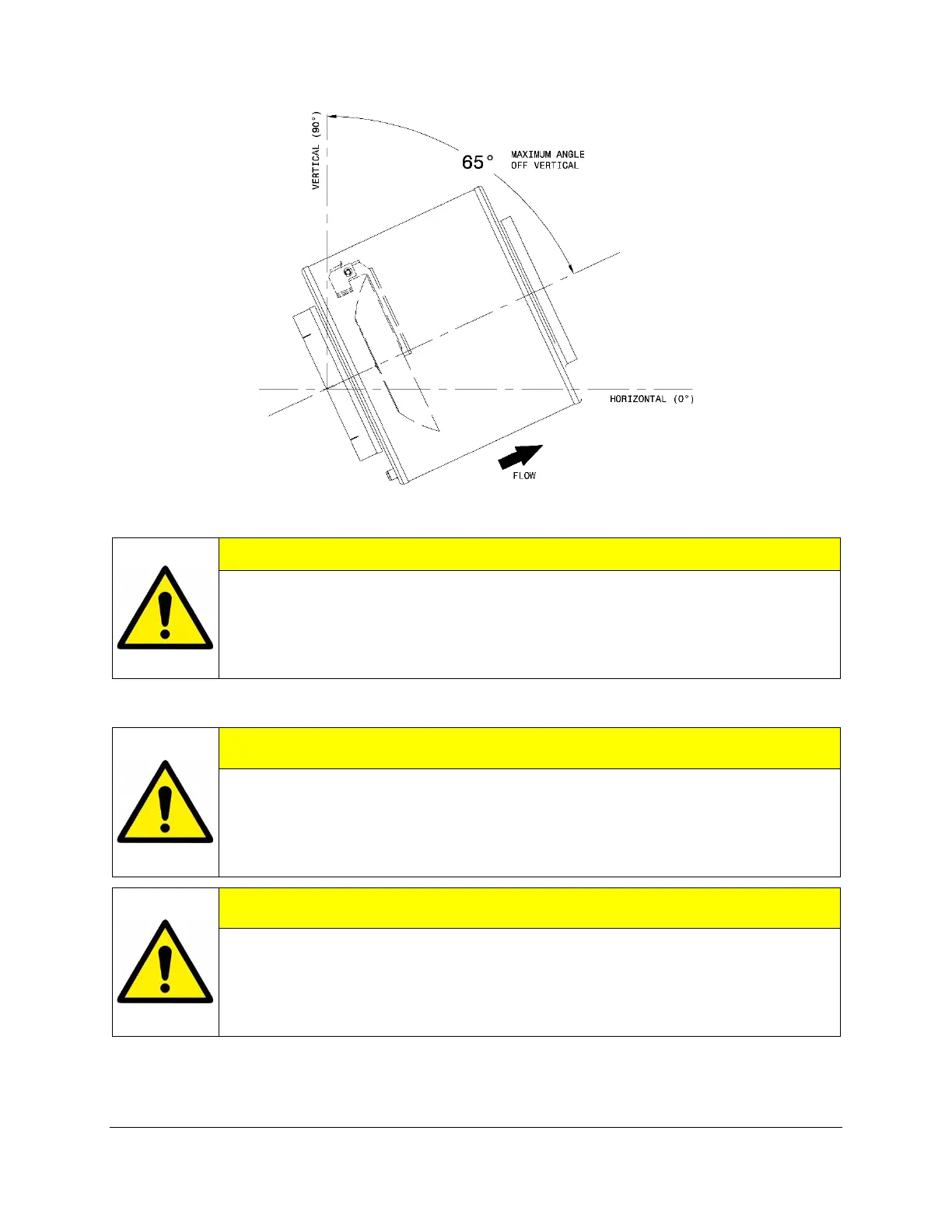

Figure 24. Backflow Valve Requirements

If an automatic isolation valve (separate from Capstone’s backflow valve) is

installed, the customer must provide a level 4 fault input from the valve to the

UCB as described in Section 8.3.4. This is to ensure that the microturbine will

immediately shut down, or not start, if the automatic valve is closed. Failure to do

so can cause severe damage to the microturbine.

5.4.5.2. Isolation Valve/Blanking Plate

When using an isolation valve or blind plate to isolate microturbine exhaust, the

microturbine must be locked out with a clear instruction that the isolation valve

be opened before the lockout is removed. If an engine start is attempted with a

closed valve, the bearings will fail immediately. This damage is not covered by

warranty.

Since Capstone backflow valves do not provide a bubble-tight seal, installations

sharing a common exhaust duct will allow a small amount of hot exhaust leakage

into non-operating units. The water content in this exhaust leakage may

condense in the non-operating engine recuperator and power head, potentially

causing damage to the engine.

For periods of non-operation longer than 48 hours, 100% isolation is required using a blanking

plate, gate valve, etc. between the common exhaust header and the backflow valve (see

Figure 23).

Loading...

Loading...