Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 32 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

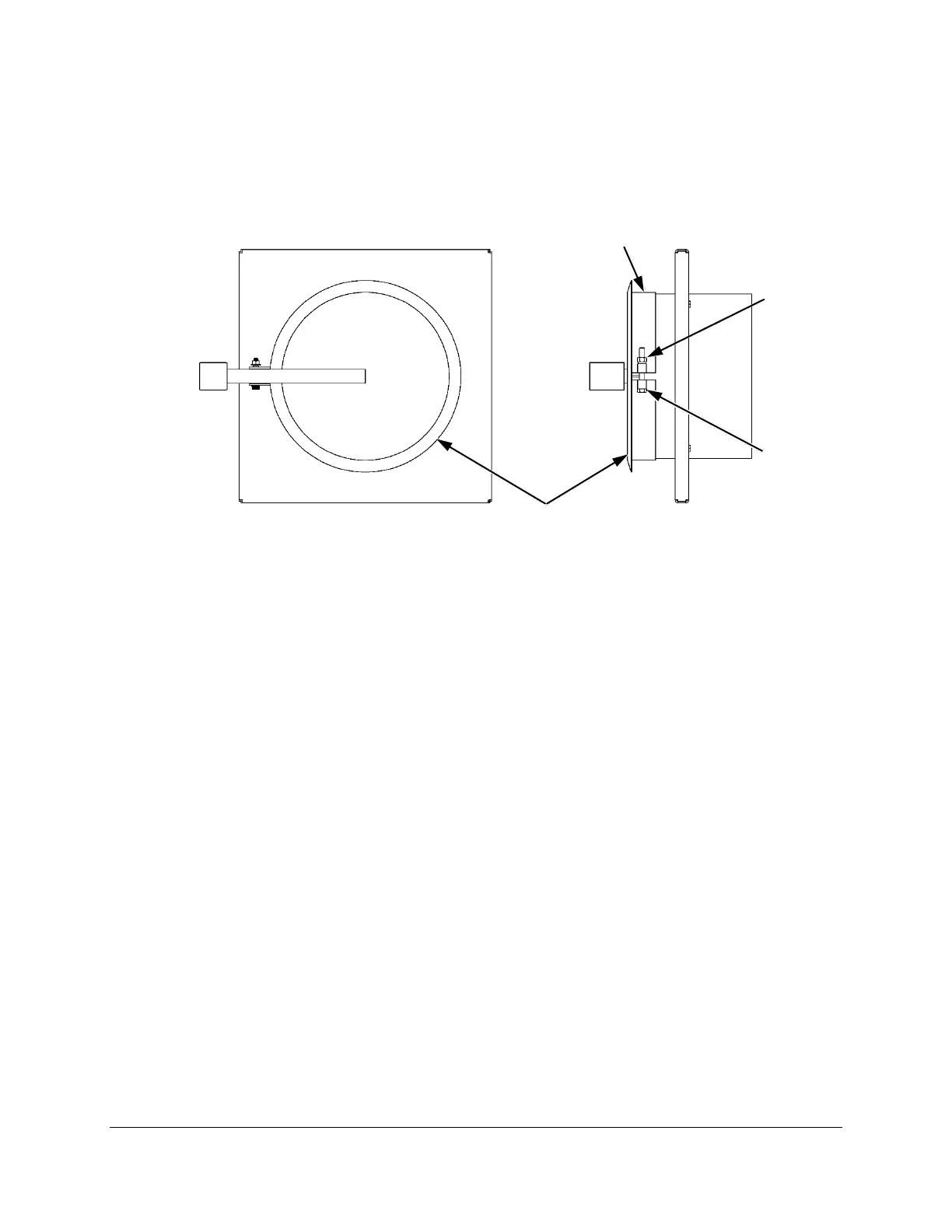

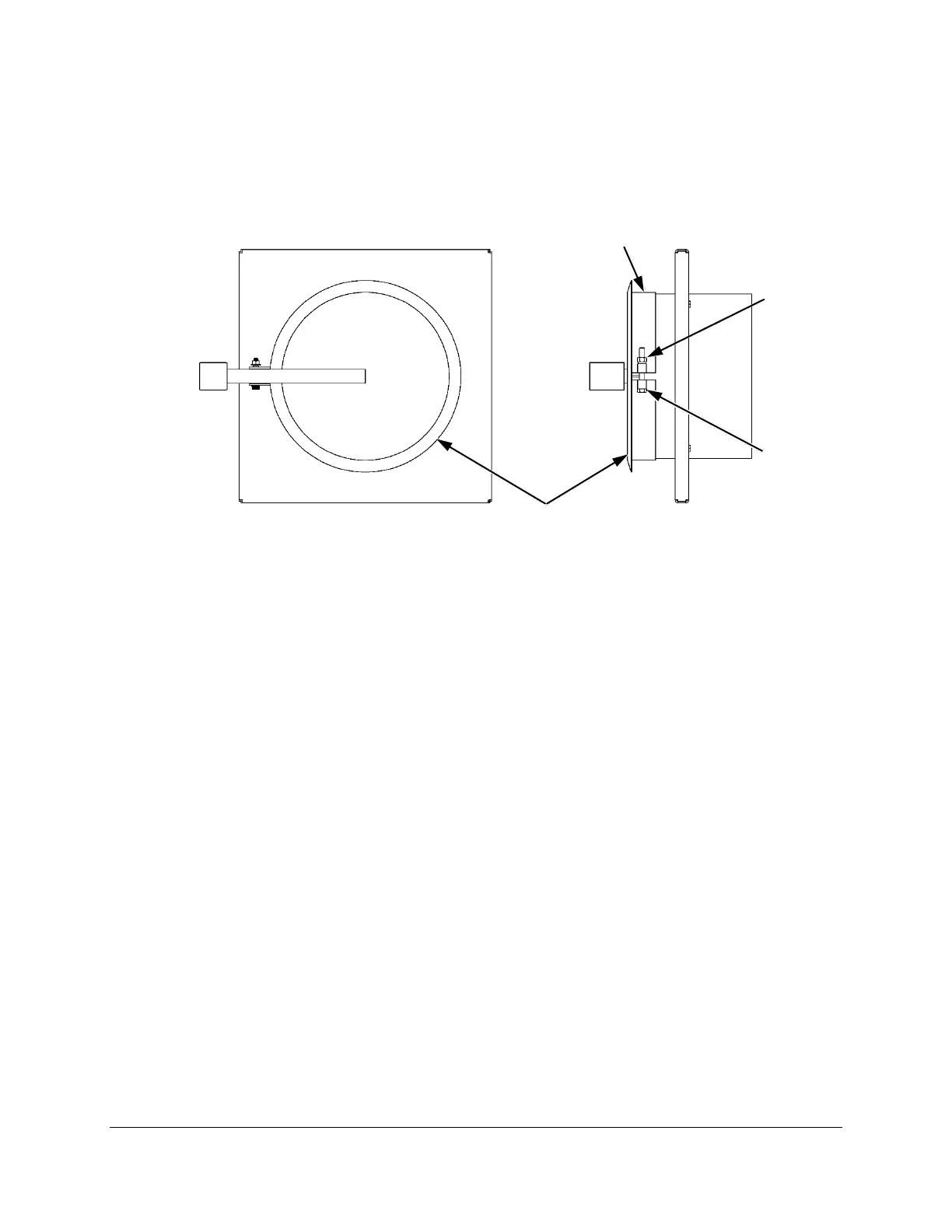

4.2.2. Rain Cap Removal

Remove the rain cap from the exhaust outlet assembly (Figure 8) by loosening the clamp ring,

which is secured by a hex screw and nut. The screw or nut can be adjusted using a 9/16-in.

wrench.

Figure 8. Exhaust Outlet Assembly

4.3. Electrical Connections

4.3.1. Electrical Conduit Installation

The access locations for all power and communication cables are shown in Figure 9. This includes

the floor access plates and side panel punch out locations. Punch holes in the side panel as

necessary only in the dimensions shown, and install water-tight conduit fittings in the punched

holes.

Before installing conduit fittings in an access plate, remove the access plate by removing the

bolts. Punch holes in each plate as necessary, and install water-tight conduit fittings in the

punched holes. The plates are secured by Class 8.8, M8 X 1.25 X 25 bolts at the factory. When

installing the access plate, torque each bolt to 25.5 Nm (18.8 ft-lb). If the factory-installed bolt

must be replaced, make sure the replacement fastener is corrosion resistant, zinc-plated steel

with M8 X 1.25 pitch thread size.

Loading...

Loading...