Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 50 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

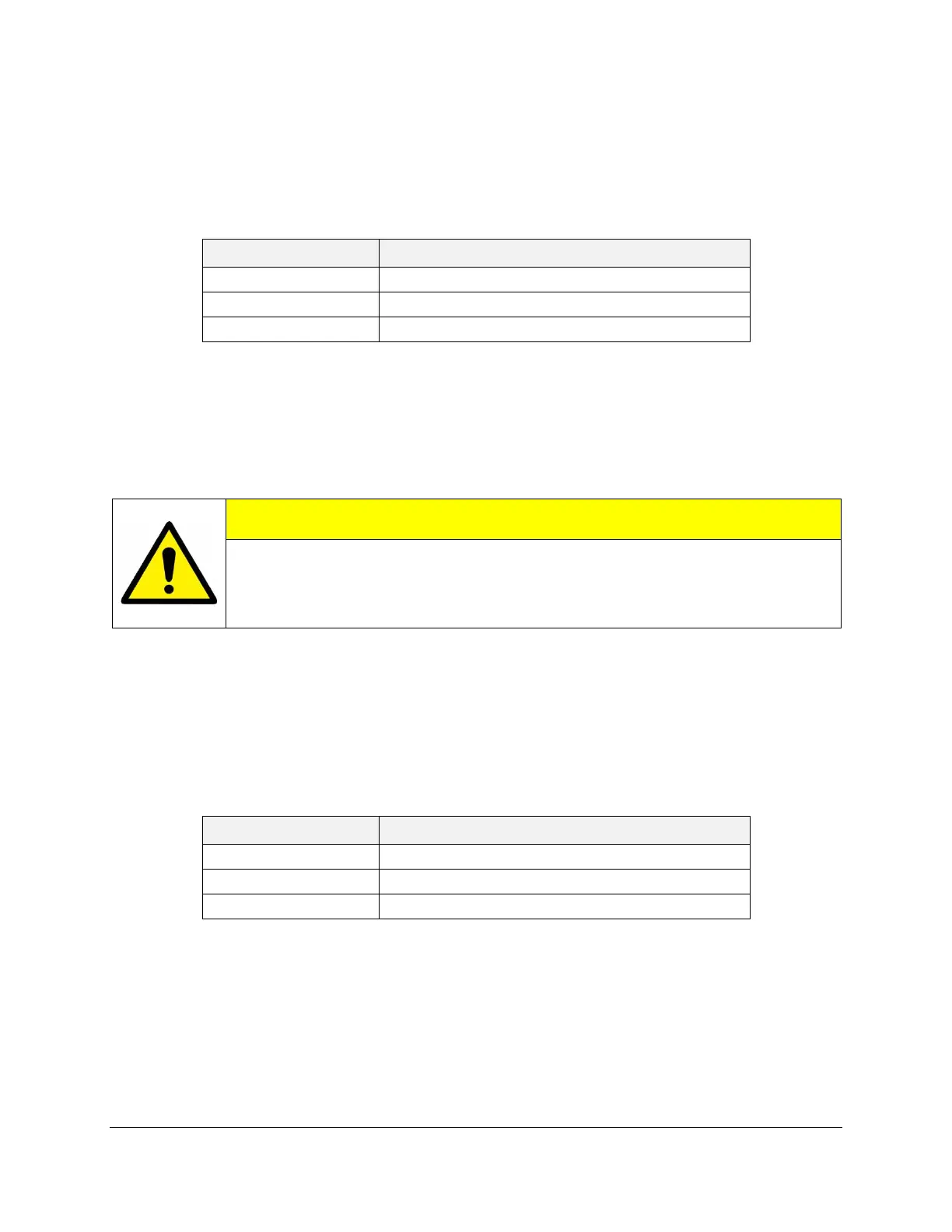

5.4.2. Air Inlet

Airflow requirements for each model are listed in Table 10. Airflow requirements are the same for

all C1000S/C800S/C600S configurations, including low pressure and dual mode versions with

batteries.

Table 10. Air Flow Requirements at ISO Conditions with Zero Backpressure

18,600 scfm (526,800 slpm)

24,800 scfm (702,400 slpm)

31,000 scfm (878,000 slpm)

In the process of producing power, the internal components — electronics, gas compressors, etc.

— produce heat. This heat must be removed by the enclosure cooling air supply under all potential

operating conditions. Following the inlet air flow rate requirements in the C1000S Product

Specification (Table 1) will ensure successful internal cooling through the full range of ambient

conditions. Additional information regarding allowable pressure drops and their effect on

microturbine performance can be found in the C1000S/C800S/C600S Technical Reference

(Table 1).

Too much inlet pressure drop can result in engine damage when installed

indoors or within a third party enclosure. The maximum allowable inlet pressure

differential to the microturbine enclosure is 249 Pa (1 inch WC) with reference

to outdoor ambient pressure.

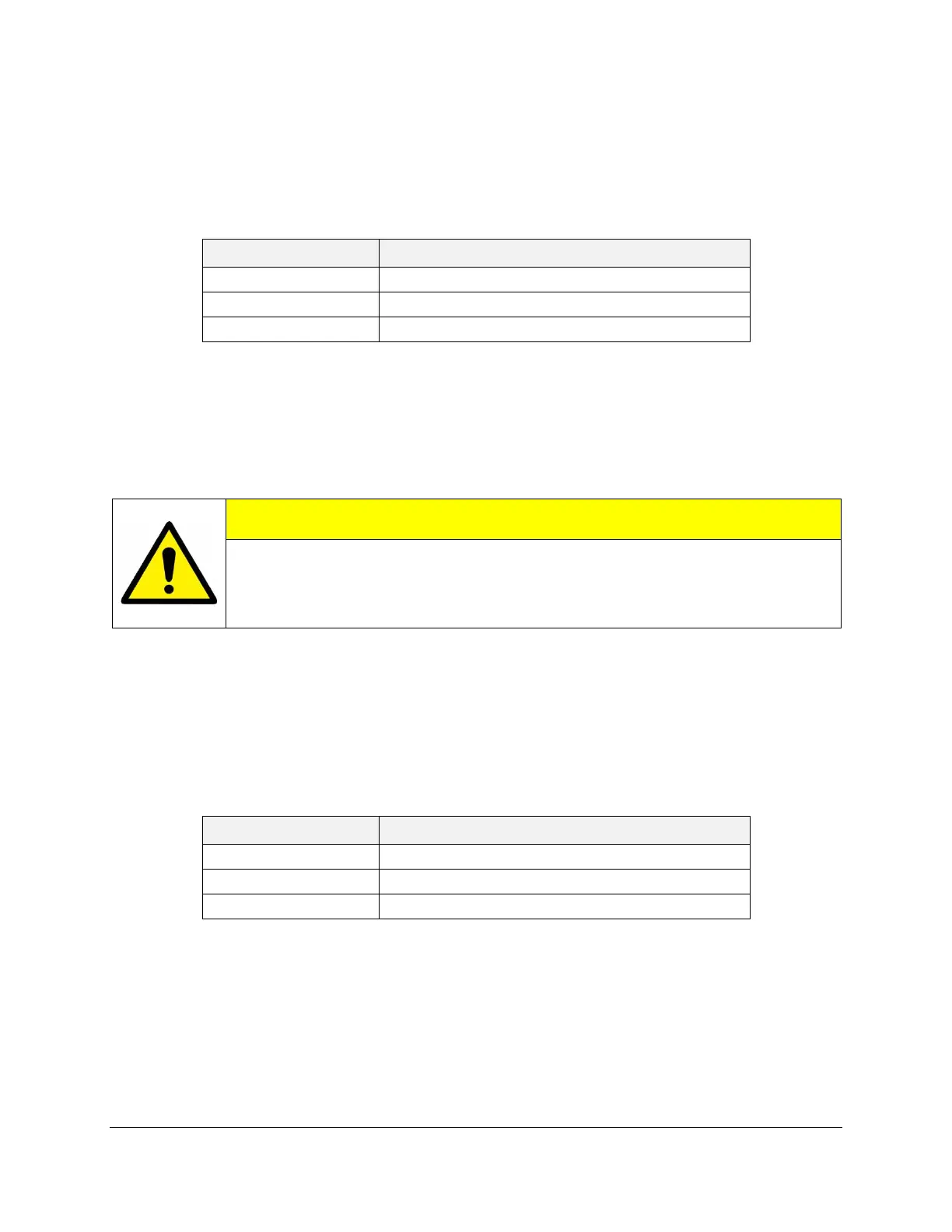

5.4.3. Enclosure/Electronics Exhaust

Enclosure/electronics exhaust can exit the microturbine enclosure at temperatures greater than

38 °C (100 °F). The microturbine must have enough ventilation to accommodate the heat rejection

levels shown in Table 11. Care should be taken around the enclosure exhaust, especially for

indoor installations. When installed outdoors, the microturbine enclosure exhaust is typically trivial

when proper installation guidelines are followed.

Table 11. Heat Rejection per Microturbine Model

5.4.4. Engine Exhaust

The engine exhaust system consists of a single pipe exiting the recuperator and vented through

the top of the enclosure. The exhaust ducting should be rated up to 371 °C (700 °F). Proper care

should be taken in the disposal of this heat, whether that disposal is in the form of heat recovery

or exhaust to the ambient air. The main objective is to transfer the hot exhaust to an acceptable

area with minimal pressure drop or flow restriction.

Loading...

Loading...