Capstone Turbine Corporation • 16640 Stagg Street • Van Nuys • CA 91406 • USA

Installation Guide: Capstone C1000S/C800S/C600S with C1000 Series Controller

480064 Rev C (December 2018) Page 42 of 122

Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without

incurring any obligation either with respect to equipment previously sold or in the process of construction.

5.2. Orientation

Orientation is an important element of site design. Items to consider are as follows:

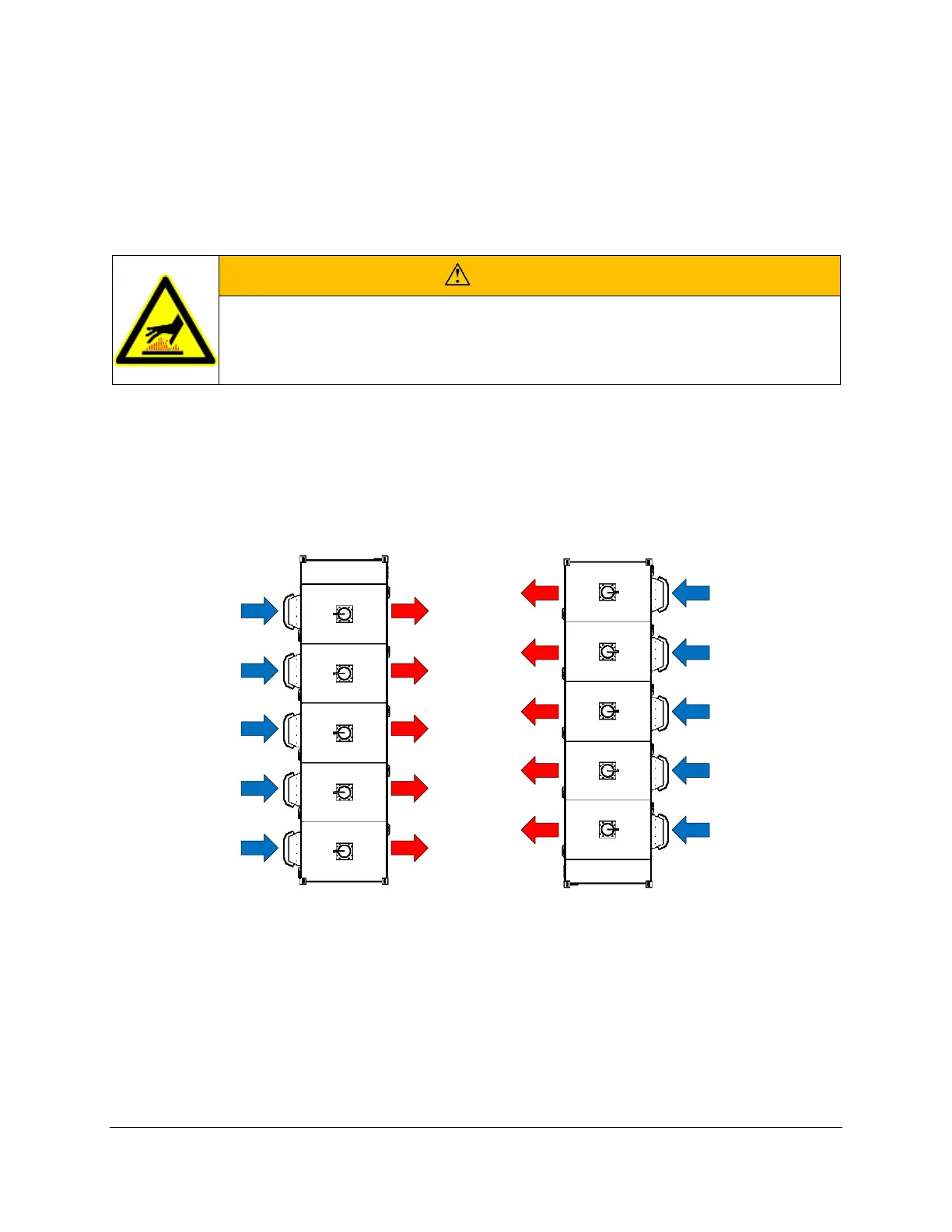

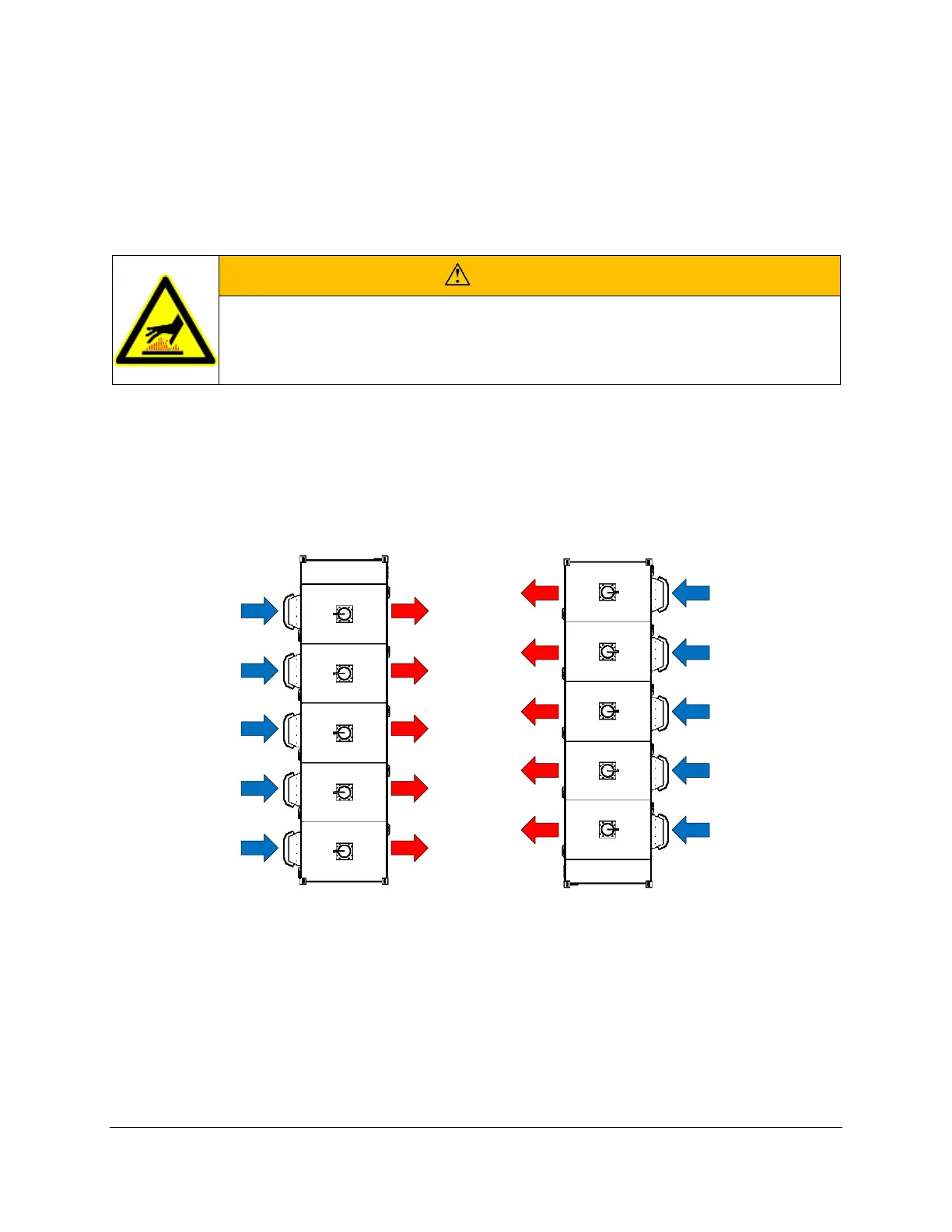

When installing multiple systems, place microturbines such that the exhausted engine

and electronics air does not get ingested into the air intake of a nearby microturbine, as

this will de-rate power output. See Figure 15 through Figure 17 for layout examples.

HOT AREA: When microturbines are oriented per Figure 15, the temperature at

the enclosure exhausts between microturbines can exceed 66 °C (150 °F).

To prevent injury, when replacing/servicing an engine in one bay, shut down all

bays in both enclosures that are oriented in this way.

Ideally, the inlet will face away from dirty areas — areas containing atmospheric

pollutants such as acidic fumes, cement dust, stone dust, cotton fibers, furnace

chemicals, etc.

Microturbines consuming air heated above the local ambient temperature may produce

less power due to de-rating.

Figure 15. Microturbine Orientation Example #1

Loading...

Loading...