5-2 Installing the 6200 network element

6200 Packet-Optical Platform Installation, Commissioning, and Testing Procedures

Release 1.1 009-6200-201 Draft Issue 1

Copyright

©

2014 Ciena

®

Corporation September 2014

Note 3: The fastening of screws is to be done at both ends uniformly.

Engage two to three threads on both ends before tightening the screws

completely. It is important to align the screws prior to tightening to avoid

screw jamming.

The 6200 NE with Rel 1.1 S/W version supports the following two

configurations for the circuit packs:

• 15G MRO XC circuit pack

• 60G MRO XC circuit pack

This chapter describes the various installation procedures for the combined

chassis (base chassis fitted with the expansion chassis). If you have

purchased only the base chassis, then, some of the information such as the

number of mounting screws, installation toolkit and mechanic kit will differ. For

details, refer to Table 5-1.

Note: While changing the mount angle from 19” to 21” or 23”, do not

handle the combined chassis without the mount angle

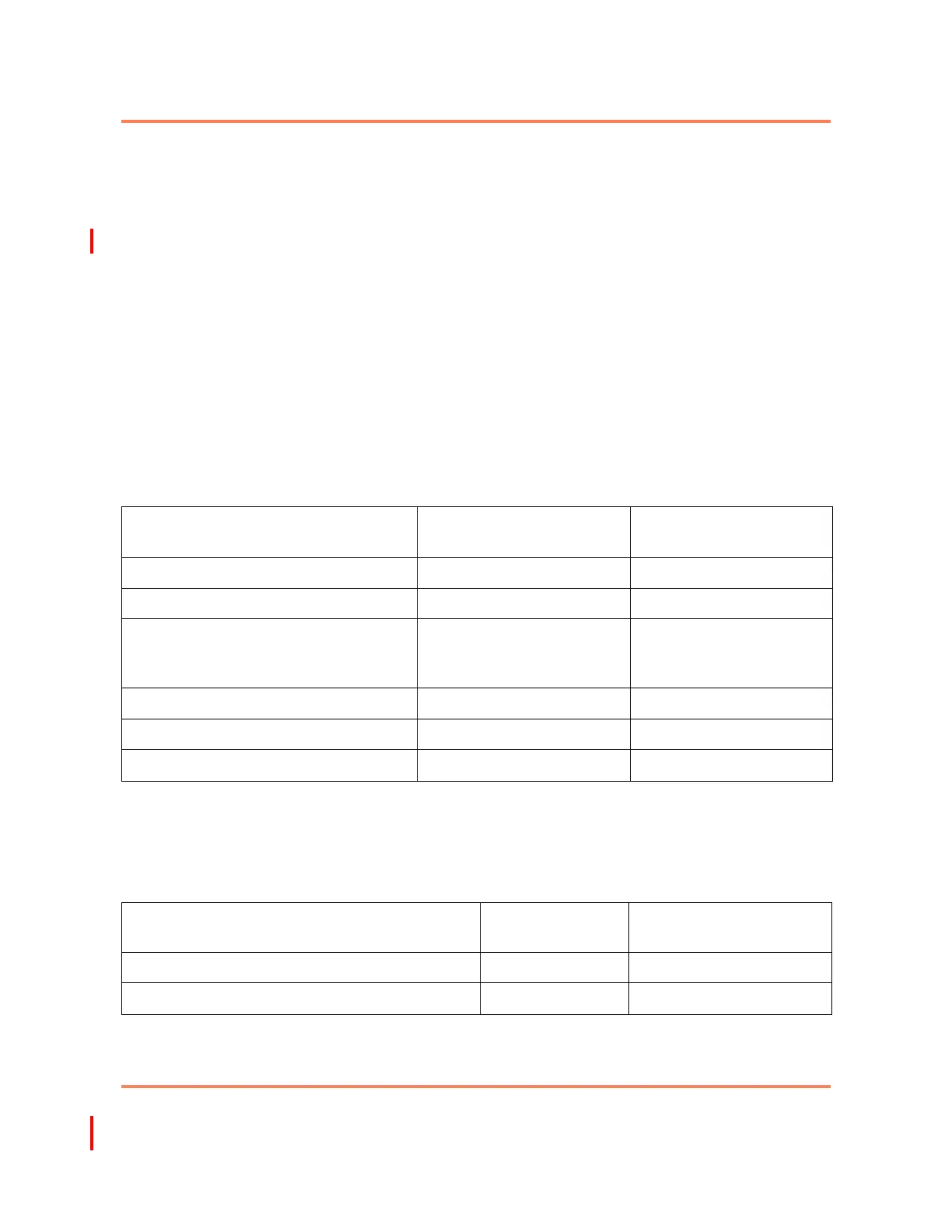

Table 5-1

List of accessories in the mechanical kit

Accessory For base/main chassis For base/main +

expansion chassis

M6 captive screws and nuts 4 8

M6 pan head screws to fix cable routers 4 (required) / 8 (provided) 8 (required) /16 (provided)

M3 screws to fix mount angles (CSK

screws for base/main chassis and

flat-head screws for expansion chassis)

10 (required) / 20 (provided) 22 (required) / 44 (provided)

21” mount angles 2 (1-R and 1-L) 2 (1-R and 1-L)

23” mount angles 2 (1-R and 1-L) 2 (1-R and 1-L)

Cable routers 2 (1-R and 1-L) 4 (2-R and 2-L)

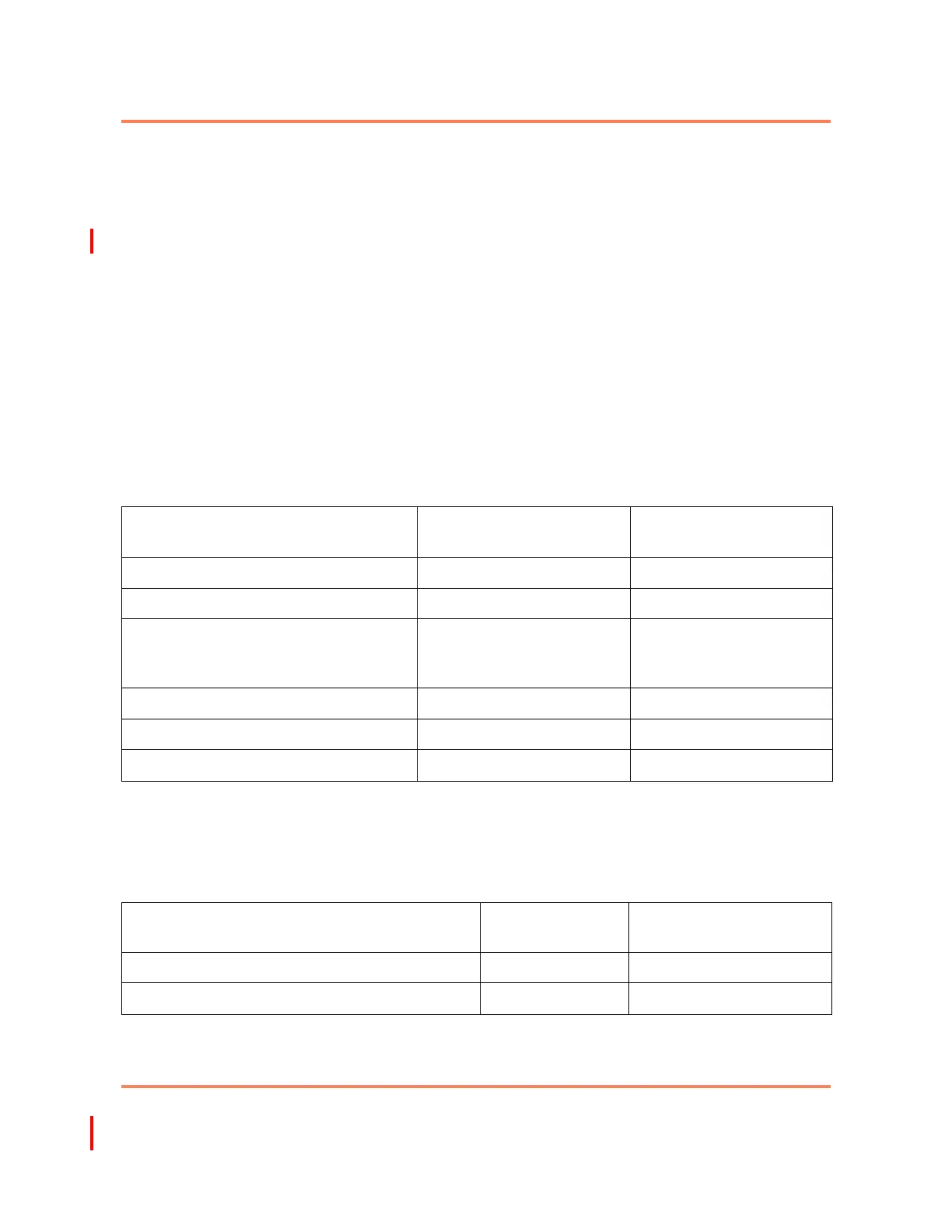

Table 5-2

Number of grounding and power cables required

Accessory For base/main

chassis

For base/main +

expansion chassis

Grounding cables 1 2

Power cables 2 4

Loading...

Loading...