7 Electrical Installation

7.1 Connections

7.1.1 Torque Settings

When tightening electrical connections, it is important to use a torque wrench to obtain the correct torque. Torque that is

too low or too high results in a bad electrical connection.

See the torque settings in Table 7.1.

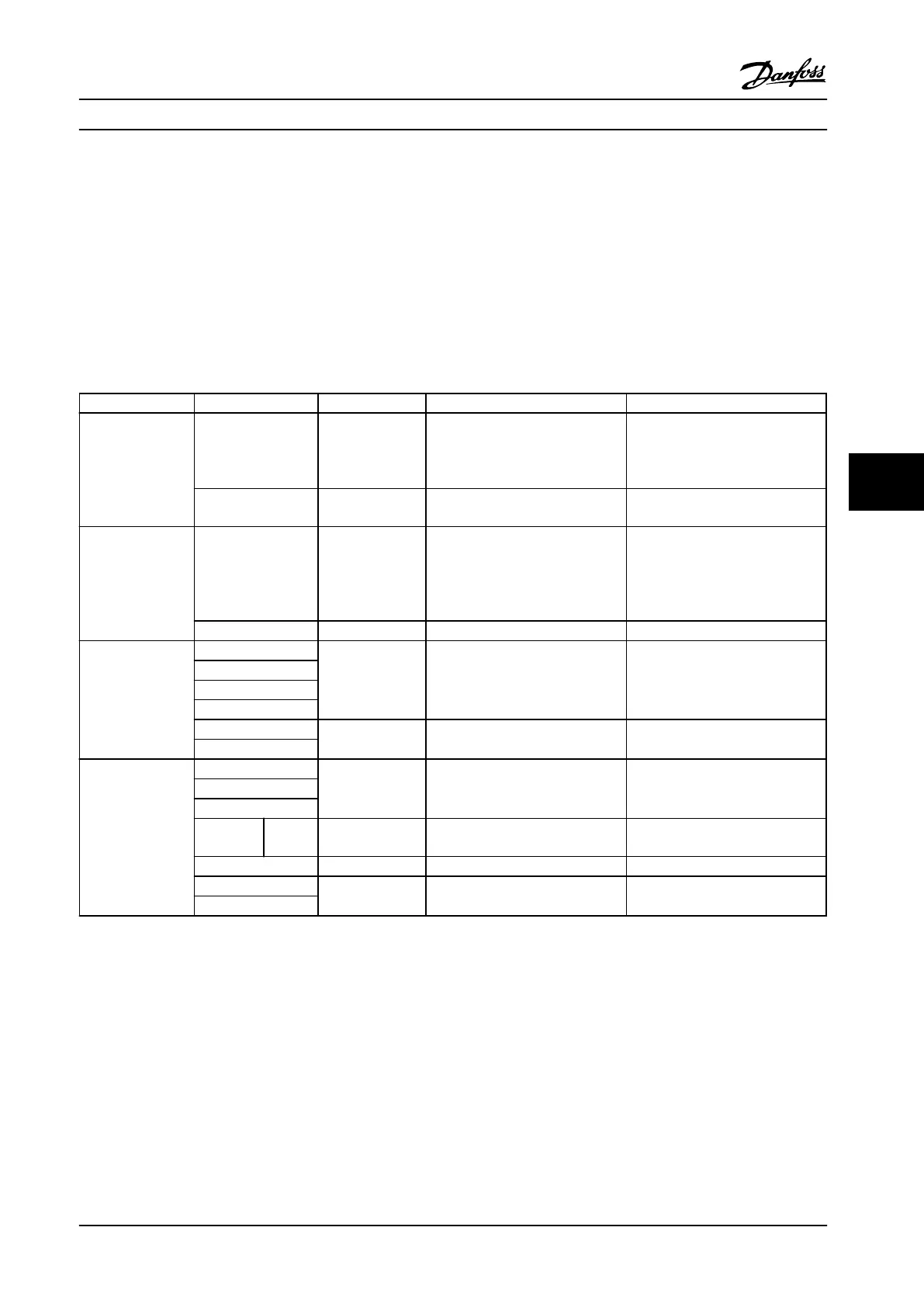

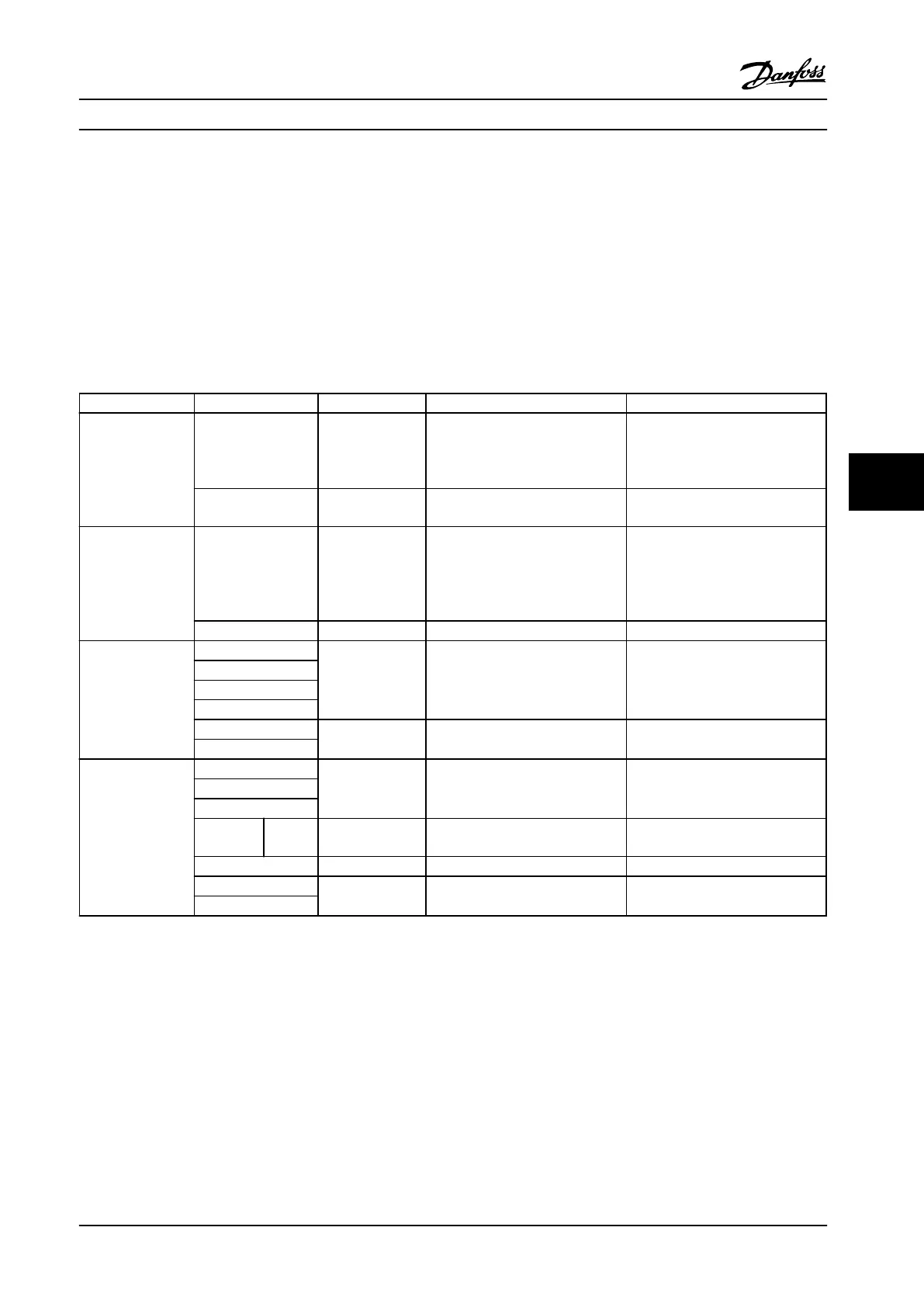

Frame size Terminal Size Torque nominal [Nm (in-lbs)] Torque range [Nm (in-lbs)]

D1h/D3h/D5h/D6h Line power

Motor

Load sharing

Regeneration

M10 29.5 (261) 19–40 (168–354)

Ground

Brake

M8 14.5 (128) 8.5–20.5 (75–181)

D2h/D4h/D7h/D8h Line power

Motor

Regeneration

Load Sharing

Ground

M10 29.5 (261) 19–40 (168–354)

Brake M8 8.5–20.5 (75–181)

E Line power M10 19.1 (169) 17.7–20.5 (156–182)

Motor

Load Sharing

Ground

Regen M8 9.5 (85) 8.8–10.3 (78.2–90.8 in-lbs.)

Brake

F Line power M10 19.1 (169) 17.7–20.5 (156–182 in-lbs.)

Motor

Load Sharing

Regen: DC-

DC+

M8

M10

9.5 (85)

19.1 (169)

8.8–10.3 (78.2–90.8)

17.7–20.5 (156–182)

F8-F13 Regen M10 19.1 (169) 17.7–20.5 (156–182.)

Ground M8 9.5 (85) 8.8–10.3 (78.2–90.8)

Brake

Table 7.1 Terminal Tightening Torques

Electrical Installation Design Guide

MG34S222 Danfoss A/S © Rev. 2014-02-10 All rights reserved. 179

7 7

Loading...

Loading...