3.4.10 Optimization of the process

regulator

After the basic settings have been made, optimize the

following:

•

Proportional gain

•

Integration time

•

Differentiation time

In most processes, this can be done by following these

steps:

1. Start the motor.

2.

Set 7-33 Process PID Proportional Gain to 0.3 and

increase it until the feedback signal begins to

vary continuously. Then, reduce the value until

the feedback signal has stabilized. Now lower the

proportional gain by 40–60%.

3.

Set 7-34 Process PID Integral Time to 20 s and

reduce the value until the feedback signal begins

to vary continuously. Increase the integration

time until the feedback signal stabilizes, followed

by an increase of 15%–50%.

4.

Only use 7-35 Process PID Differentiation Time for

very fast-acting systems only (differentiation

time). The typical value is four times the set

integration time. The differentiator should only be

used when the setting of the proportional gain

and the integration time has been fully

optimized. Make sure that oscillations on the

feedback signal are sufficiently dampened by the

low-pass filter on the feedback signal.

NOTICE!

If necessary, start/stop can be activated a number of

times to provoke a variation of the feedback signal.

3.4.11 Ziegler Nichols Tuning Method

Several tuning methods can be used to tune the PID

controls of the adjustable frequency drive. One approach is

to use the Ziegler Nichols tuning method.

NOTICE!

The method described must not be used on applications

that could be damaged by the oscillations created by

marginally stable control settings.

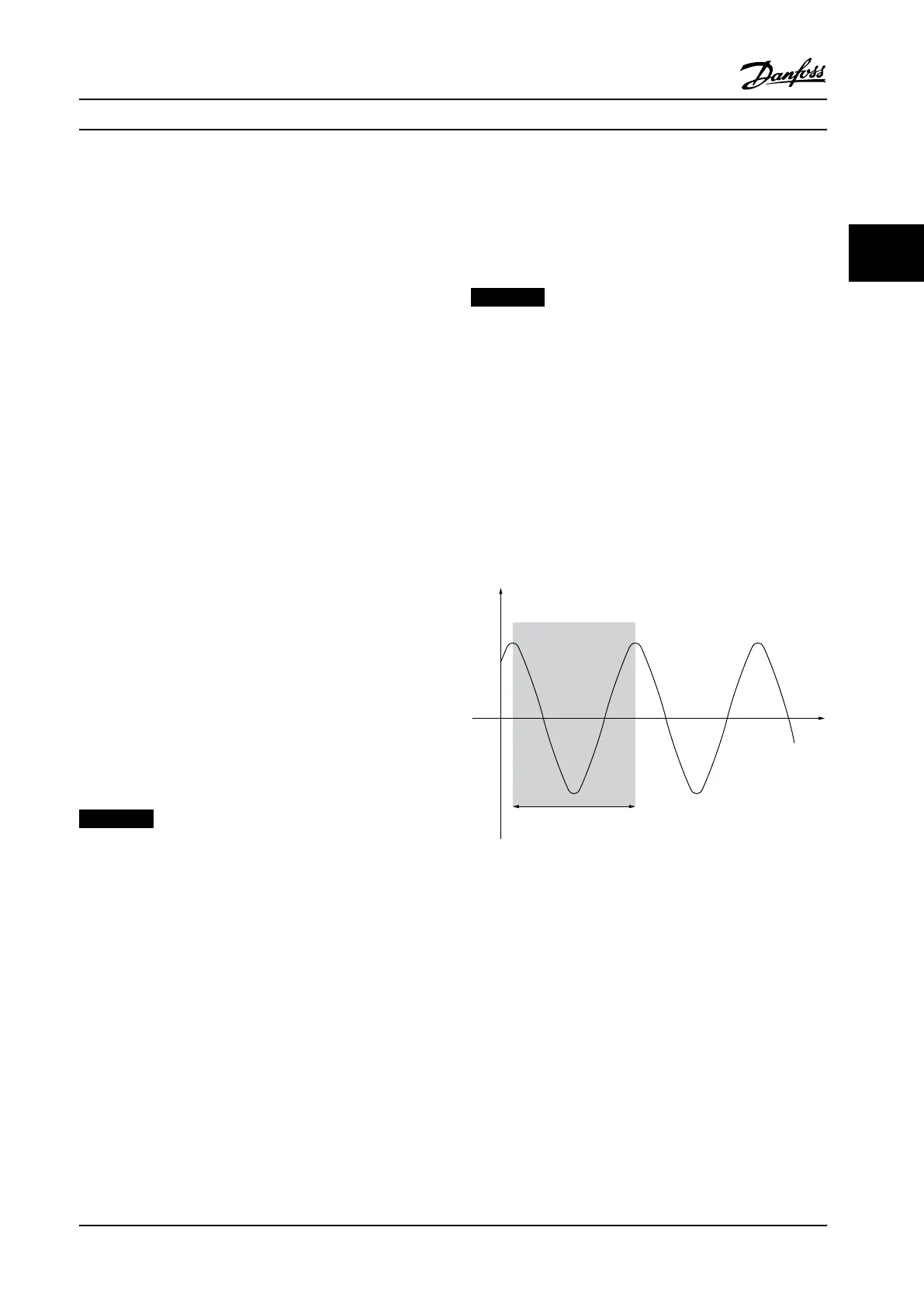

The criteria for adjusting the parameters are based on

evaluating the system at the limit of stability rather than

on taking a step response. The proportional gain is

increased until continuous oscillations are observed (as

measured on the feedback), that is, until the system

becomes marginally stable. The corresponding gain (K

u

) is

called the ultimate gain. The period of the oscillation (P

u

)

(called the ultimate period) is determined as shown in

Figure 3.25.

Figure 3.25 Marginally Stable System

Product Introduction Design Guide

MG34S222 Danfoss A/S © Rev. 2014-02-10 All rights reserved. 45

3 3

Loading...

Loading...