3.4 PID Control

3.4.1 Speed PID Control

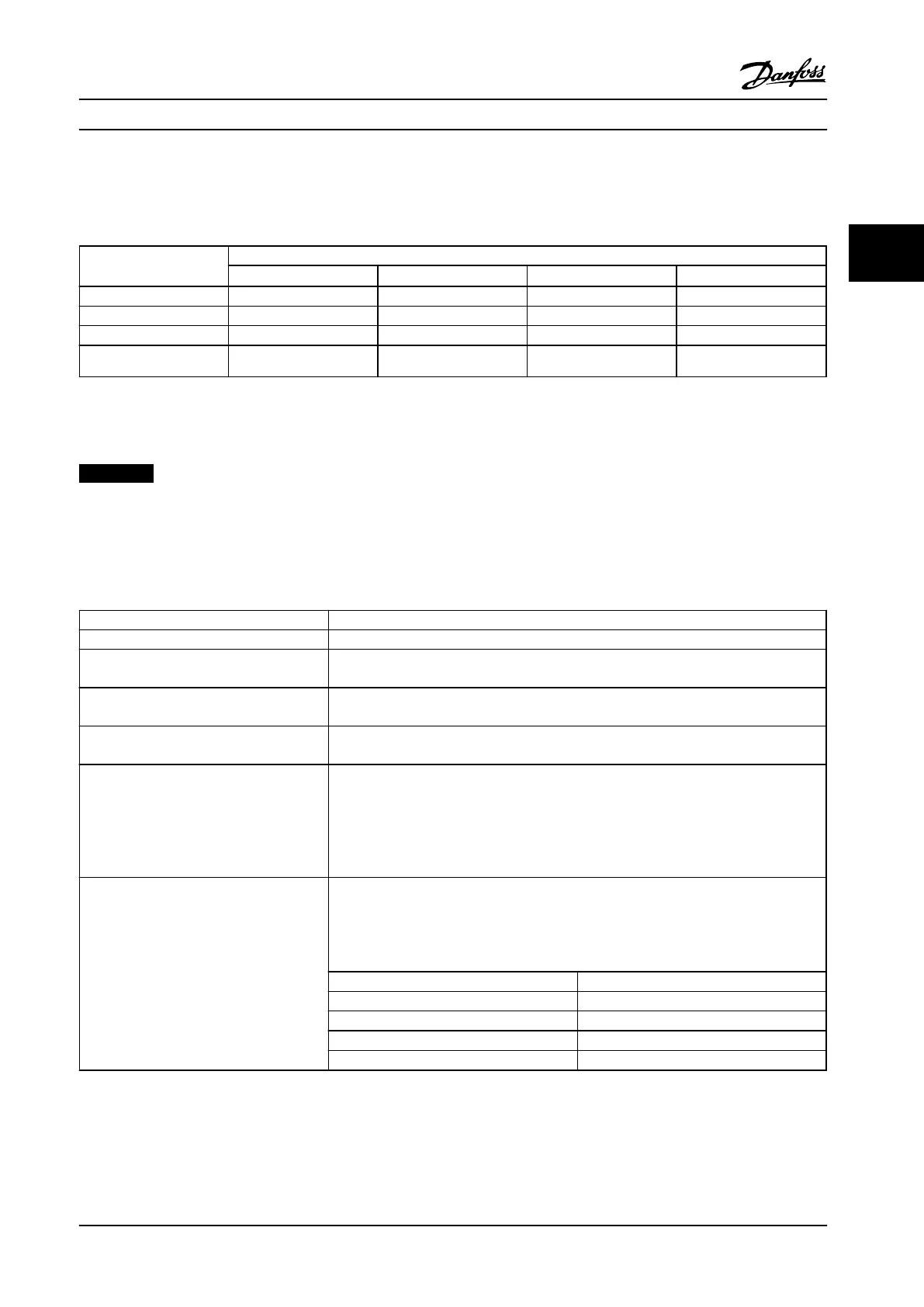

1-00 Configuration Mode 1-01 Motor Control Principle

U/f

VVC

plus

Flux sensorless Flux w/ enc. feedb

[0] Speed open-loop Not Active Not Active Active N.A.

[1] Speed closed-loop N.A. Active N.A. Active

[2] Torque N.A. N.A. N.A. Not Active

[3] Process Not Active Active Active

Table 3.6 Control Configurations Where the Speed Control is Active

“N.A.” means that the specific mode is not available. “Not Active” means that the specific mode is available but the Speed Control is not active in

that mode.

NOTICE!

The Speed Control PID works under the default parameter setting, but tuning the parameters is highly recommended to

optimize the motor control performance. The two flux motor control principles are particularly dependent on proper

tuning to yield their full potential.

3.4.2 Speed PID Control Parameters

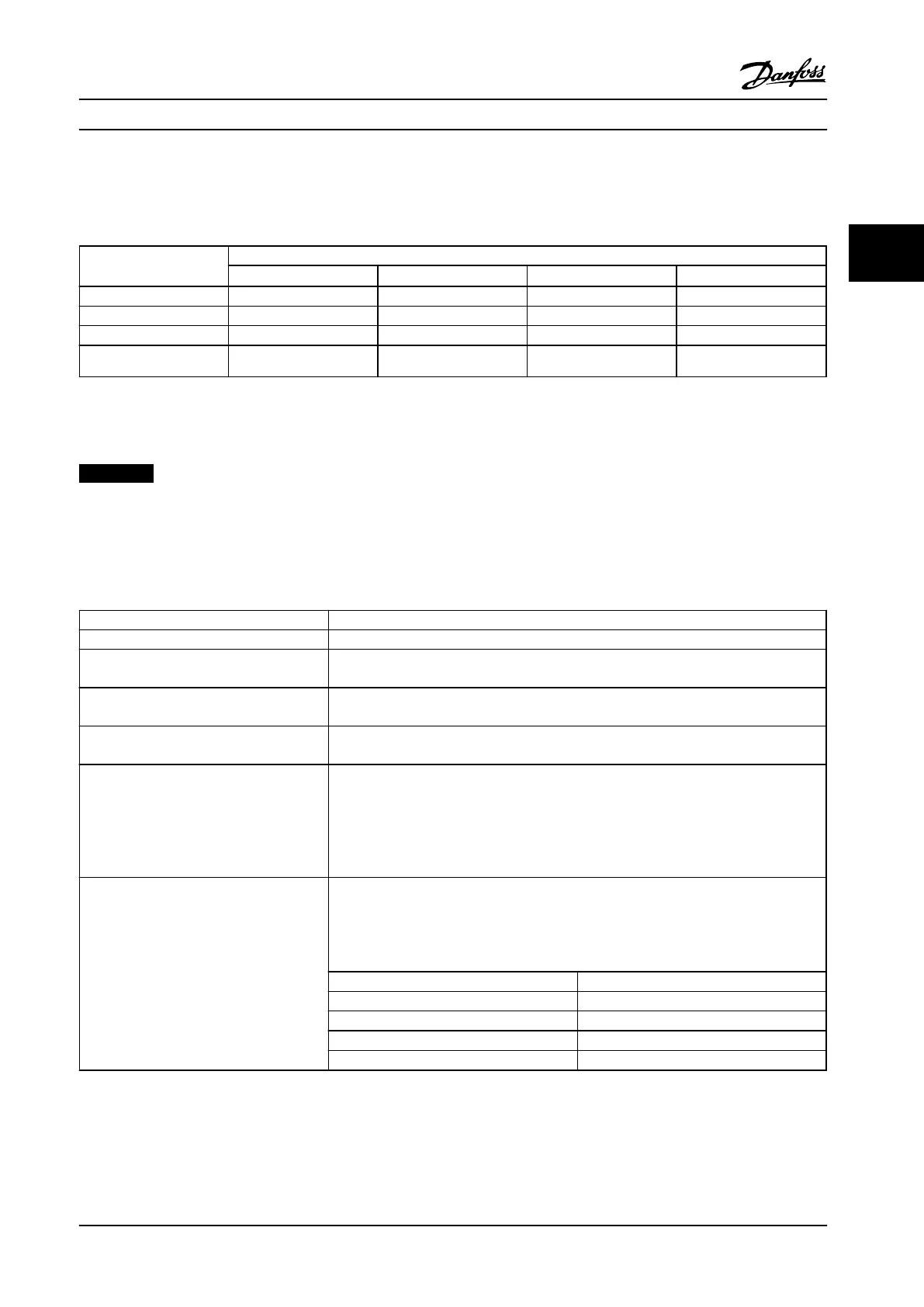

Parameter Description of function

7-00 Speed PID Feedback Source Select from which input the speed PID should get its feedback.

30-83 Speed PID Proportional Gain The higher the value, the quicker the control. However, too high a value may lead to

oscillations.

7-03 Speed PID Integral Time Eliminates steady state speed error. Lower value means quick reaction. However, too low a

value may lead to oscillations.

7-04 Speed PID Differentiation Time Provides a gain proportional to the rate of feedback change. A setting of zero disables the

differentiator.

7-05 Speed PID Diff. Gain Limit If there are quick changes in reference or feedback in a given application - which means

that the error changes swiftly - the differentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

differentiator gain is. The differentiator gain can thus be limited to allow setting of the

reasonable differentiation time for slow changes and a suitably quick gain for quick

changes.

7-06 Speed PID Lowpass Filter Time A low-pass filter dampens oscillations to the feedback signal and improves steady state

performance. However, too large a filter time will deteriorate the dynamic performance of

the speed PID control.

Practical settings of 7-06 Speed PID Lowpass Filter Time taken from the number of pulses

per revolution from encoder (PPR):

Encoder PPR 7-06 Speed PID Lowpass Filter Time

512 10 ms

1024 5 ms

2048 2 ms

4096 1 ms

Table 3.7 Relevant Parameters for the Speed PID Control

Product Introduction Design Guide

MG34S222 Danfoss A/S © Rev. 2014-02-10 All rights reserved. 37

3 3

Loading...

Loading...