SECTION 5 Troubleshooting

5–4 0855855eng 6/08

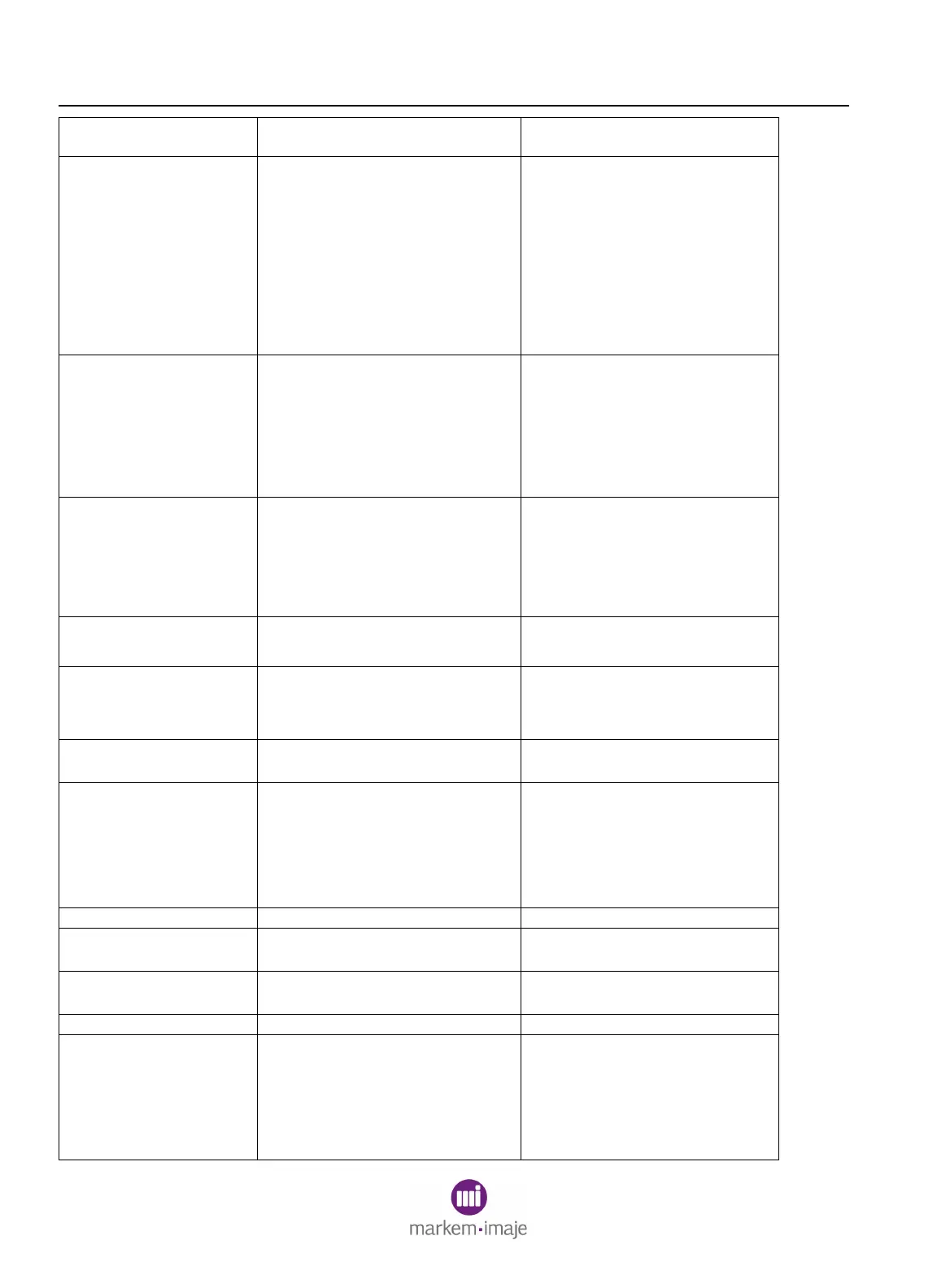

Symptom Possible Cause / Problem Reference / Action

Smudged / blurred

print (continued)

Product contacting printhead IN, 2, Mounting the Printhead

Ink can build up on the front of

the printhead. If a product

passes closely in front of the

printhead, the liquid ink can

transfer to the product,

distorting the printed image.

Image contacting guide rail IN, 2, Mounting the Printhead

When a guide rail rubs on a

printed image, small amounts

of ink may be transferred. In

time, the ink build up will

smudge the printed image

Airflow near printhead IN, 2, Mounting the Printhead

Airflow in the vicinity of the

printhead may cause a

redirection of the ink droplets,

blurring the printed image

Encoder line speed mismatch IN, 5, Encoder Line Speed

SE, 4, Print Station; Encoder

Print is stretched,

condensed, or tilted

Encoder line speed mismatch

Model 5200/5400SC with tilted

printhead

IN, 5, Encoder Line Speed

Use external encoder

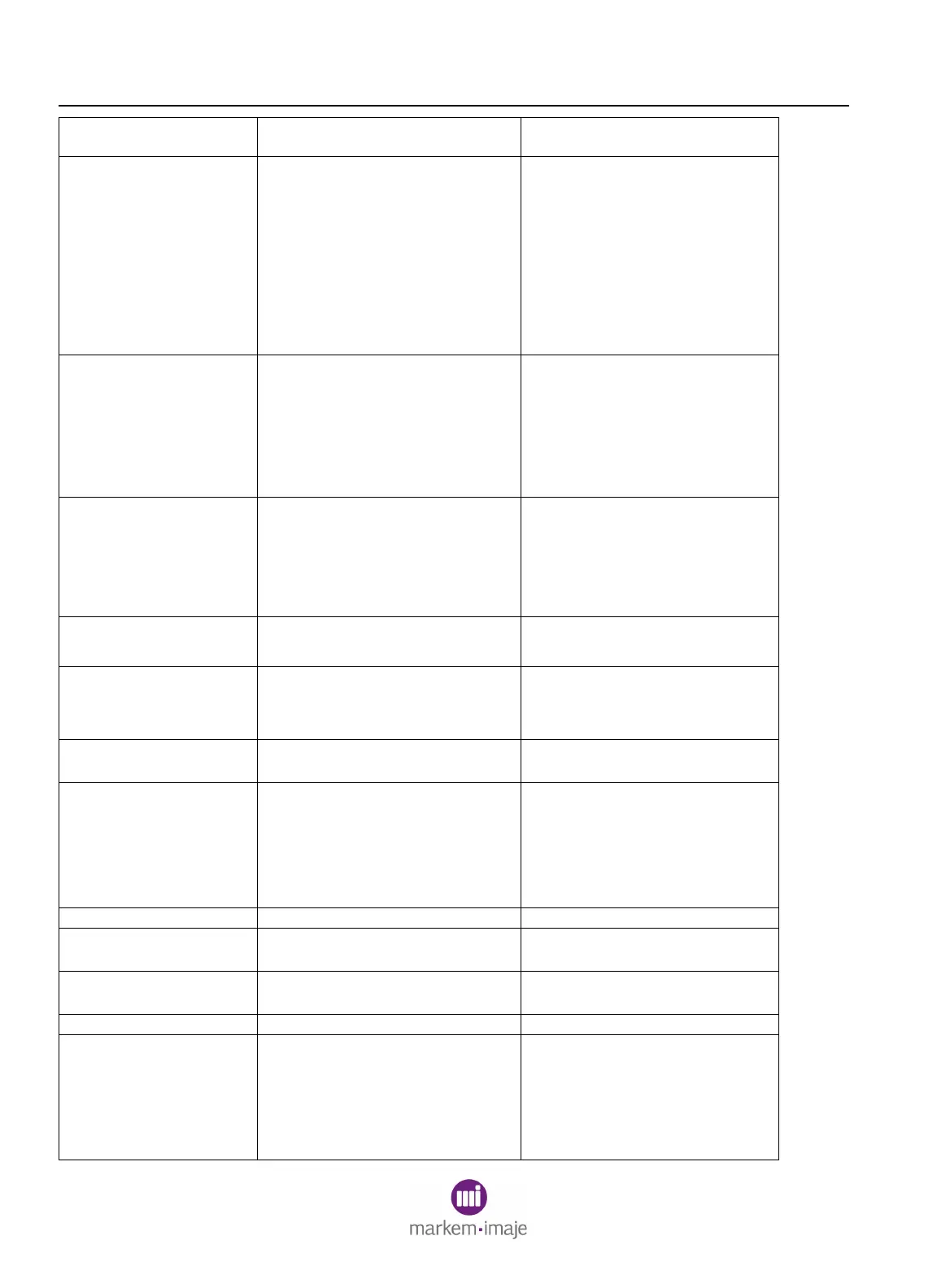

Missing jets / jets drop

out

Contamination SE, 3, Daily Cleaning of the

Printhead

Incorrect low vacuum IN, 2, Connecting Umbilical

Lines to the Printhead

IN, 3, Printhead Vacuum

Settings

SE, 4, VPC 1-2 and 3-4

Incorrect high vacuum SE, 4, VPC 1-2 and 3-4

No ink in the printhead SE, 4, Ink System; Printhead

Ink Level

Electrostatic Discharge (ESD) IN, 2, Electrical

IN, 5, Not Printing

Vibration or mechanical shock IN, 5, Print Quality

Auto Purge is enabled

Auto Purge with down jetting

orientation

Printing too soon after Auto

Purge

IN, 3, Auto Purge Frequency

SE, 3, Auto Purge Spacing

Guidelines

SE, 3, Auto Purge Spacing

Guidelines

Loading...

Loading...