3

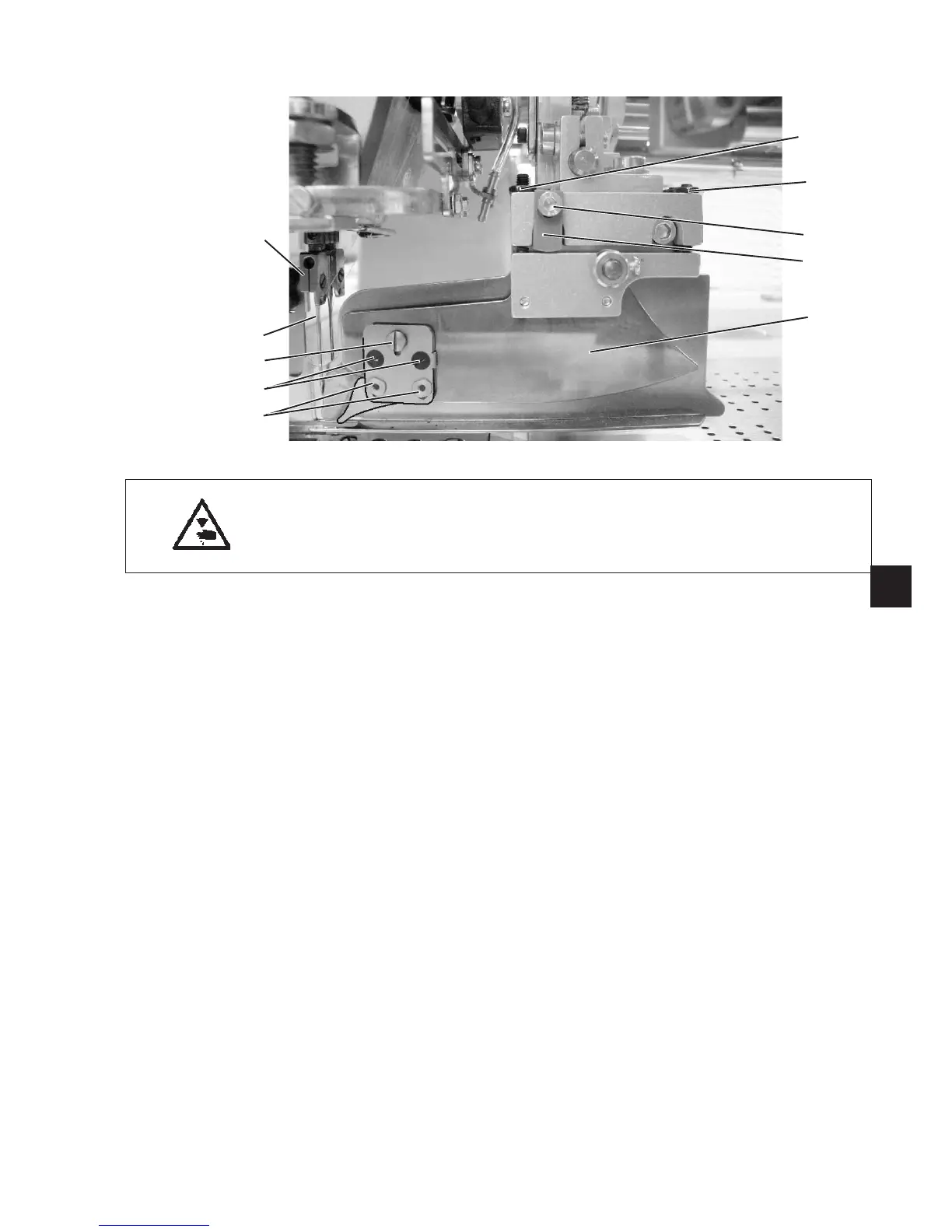

12.4 Adjusting the guide plates with additional spring loaded downholder at the folder

Caution: Danger of injury !

Switch off the main switch.

Check and adjust the guide plates only with the main switch

switched off.

Standard checking

According to the material thickness and considering whether the flap is

to be positioned on the right or on the left the height of the guide plates

has to be adjusted in such a way that they can easily be lifted by the

workpiece. The guide plates have to be close beside the needles, but

must not touch the needles or the needle block.

The guide plates and the spring loaded downholder should press the

fabric in a controlled way during the sewing process.

The independent setting of the guide plates and the spring loaded

downholder (position and pressure) allows a better processing of

various materials.

–

Check the position of the guide plates.

–

Check the spring pressure (important with regard to the folding and

seam quality).

–

Check the free movement of the needles 2 and needle block 3 with

regard to the guide plates.

Correction

Adjusting the guide plates with spring loaded downholder.

–

Loosen nut 5.

–

Adjust the guide plates height with the core pin in nut 5.

–

Tighten nut 5.

–

Adjust the stop 9,

for this purpose loosen the screw 10 and set the stop.

The stop 9 should prevent the collision of the downholder against

the needle in raised position.

95

4

5

10

9

1

3

2

8

6

7

Loading...

Loading...