H Service Omega 2

H Service

1 Inspection and cleaning intervals

If a test image was printed after the print heads were cleaned, the

software saves t his information. Warranty and guarantee claims can

only be made if the following conditio ns are ful fi lled:

– The test images made after wiping with a wet cloth are retained.

–Allspecified maintenance work is carried out.

Extracts from the following chapters, either as a PDF or film, on

important service work can be fou n d o n th e Maintenance tab under

Printer in the software.

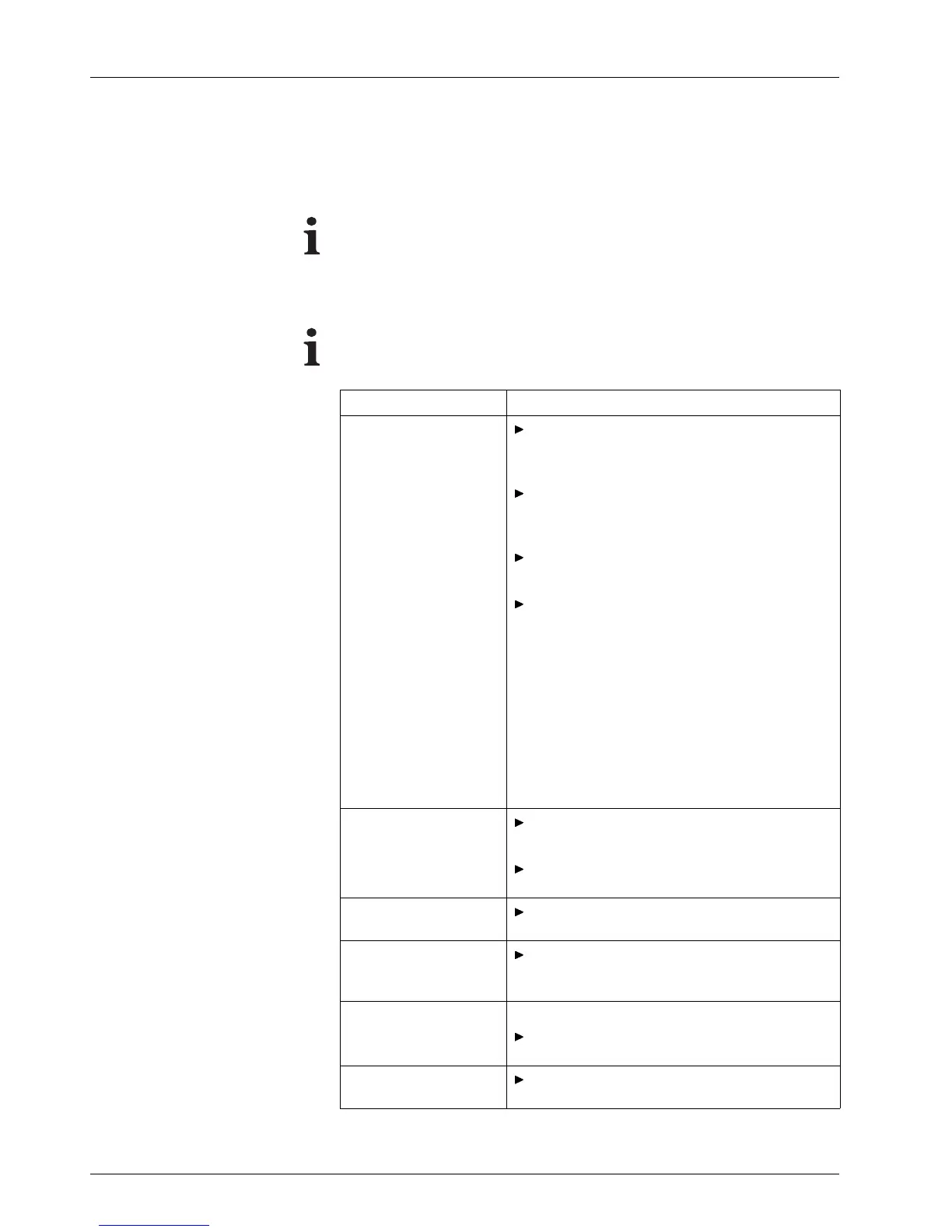

When? What?

Daily in the morning

Check conv eyor be lt f or soiling and clean if

necessary (→ Page 69 / Cleanin g con ve yor

belt).

Check loading and unloading units for

soiling and clean with slightly moist clo th if

necessary.

Clean light trap carrier (→ Page 69 / Clean

light trap carrier).

After the multiple spitting process is initiated,

carry out morning cleaning:

– Prepare for cleaning

(→ Page 79 / Preparing for clean-

ing).

– Suck out nozzles (→ Page 80 / Suc king

out nozzles).

– Print a test image.

– Wipe print heads wet if necessary

(→ Page 82 / Wiping print heads wet).

– Clean printing plate if n ecessary

(→ Page 83 / Wiping p rinting plate ).

Weekly

Lubricate carriage guide (→ Page 70 / Lubri-

cating carriage guide).

Clean UV LED (→ Page 76 / Cleaning U V

LED).

Monthly

Check encoder ruler and clean if necessary

(→ Page 71 / Cleaning encoder ruler).

Every 6 months

Change lubricating plates

(→ Page 73 / Changing lubricating

plates).

Annually Recommended:

Have inte

rmediate tank for ink changed by

Durst cu

stomer service.

Every 13000 hours or 2

years

Have Durst customer service refill transport

motor oil.

68 / 9 1 2004 – 2014 © Durst Ph ototechnik AG – www.d urst-online .com , Omega 2, Issued 0 7/20 14

Loading...

Loading...