Function of CI 3000

31

Version 2.09 09. April 2014

the system operator and information gathered by the LDSWin software from the plant power demand

profile. Correct adjustment of setpoints, meaning efficiency and reliability of the load optimization

system, can readily be reviewed and checked from this recorded data.

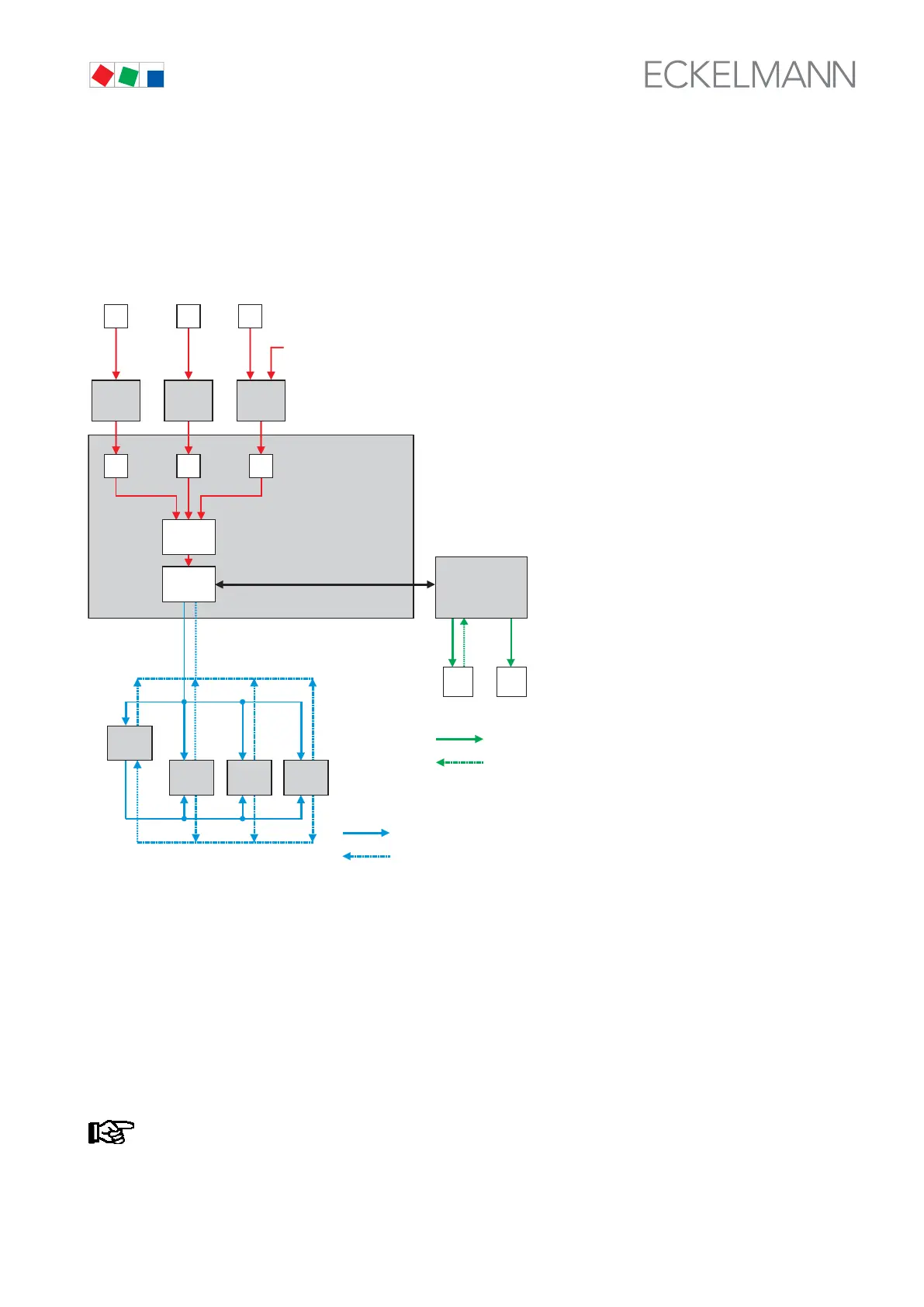

The following diagram outlines how load management acts on the various electric loads and how communica

tion takes place between LSM and the electric loads via the CAN bus:

UA 300

FAMILY

SIOX

DIGITAL IN-/

OUTPUT

ENERGY METER

ENERGY RECORD

TOTALIZER

CI 3000

OTHER CONSUMERS (E.G. BAKING OVEN, DISHWASHER)

DIGITAL SIGNALS

LOAD MANAGEMENT

BYTHE VS DELEGATED BY LSM

LOAD SHEDDING COMMAND BY CAN BUS

REQUEST/ FEEDBACK BY CAN BUS

LOAD SHEDDING COMMAND BY DIGITAL SIOX OUTPUT

FEEDBACK BY DIGITAL SIOX INPUT

VS 3000

UA 300

FAMILY

UA 300

FAMILY

CAN bus

LSM

SIOX SIOX SIOX

ZNR. 51203 68 230 E0

DIGITAL SIOX INPUTS

?

SYNCHRON IMPULSE FROM THE POWER COMPANY

4.12 M-bus Interface for consumption data capture

The M-bus (meter bus) is a field bus for the capture of e.g. gas, water or power consumption data.

It is transmitted serially from the connected meters (slaves / field devices) to a master (M-bus gateway) via a

reverse-polarity protected twin wire cable. The M bus gateway itself is connected to the store computer’s COM2

interface, the activation of the interface is carried out in menu 6-1-9.

For detailed information see chapter 5.8 “Connection of the M-bus Gateway”.

Loading...

Loading...