Proline Prowirl F 200 PROFIBUS PA Commissioning

Endress+Hauser 81

10.5.4 Configuring the analog inputs

The Analog inputs submenu guides you systematically to the individual Analog input 1 to

4 submenu. From here you get to the parameters of the individual analog input.

Navigation

"Setup" menu → Analog inputs

‣

Analog inputs

‣

Analog input 1 to 4

Channel

PV filter time

Fail safe type

Fail safe value

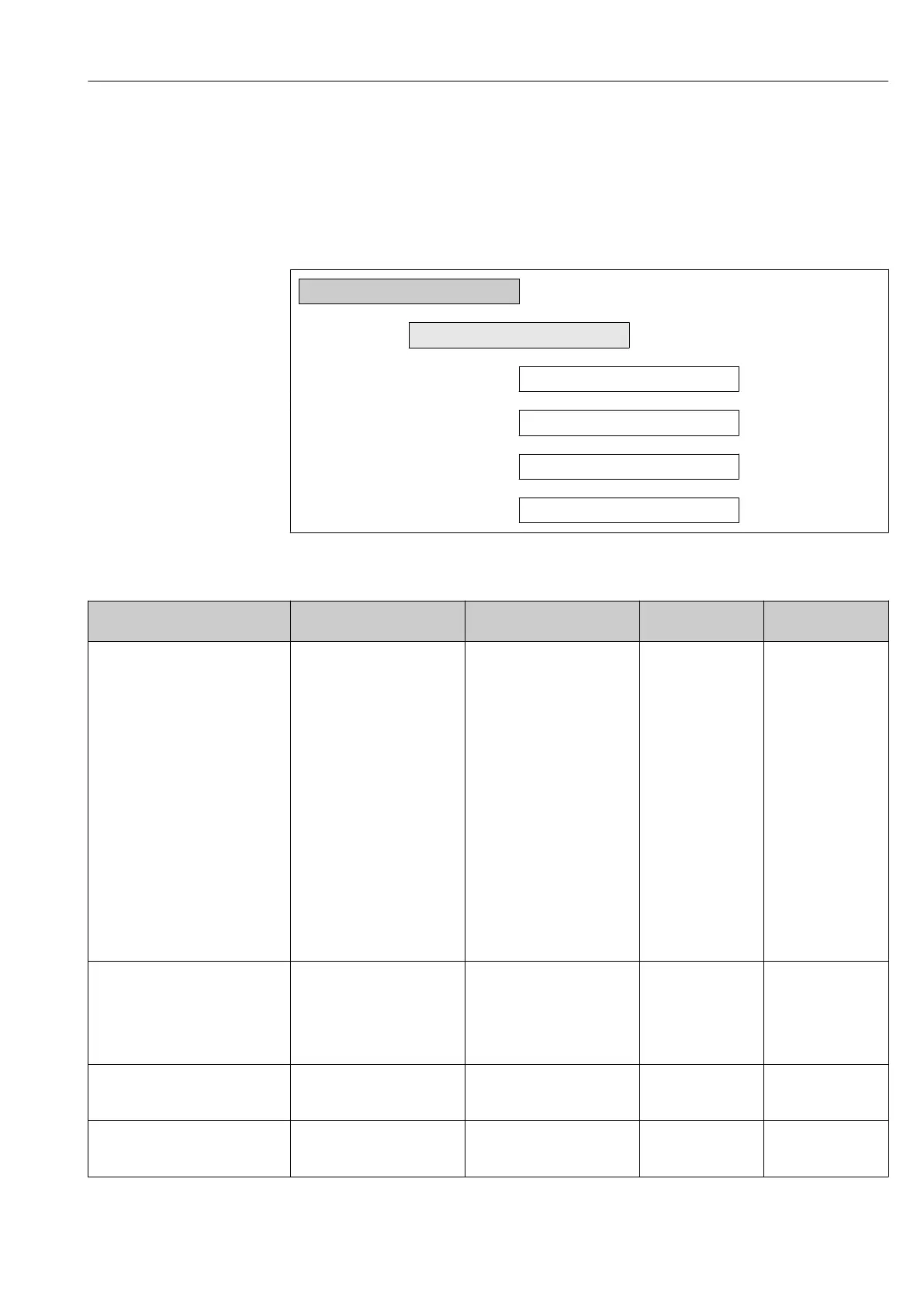

Parameter overview with brief description

Parameter Prerequisite Description Selection / User

entry

Factory setting

Channel – Select the process variable. • Volume flow

• Mass flow

• Corrected volume

flow

• Flow velocity

• Temperature

• Calculated

saturated steam

pressure

*

• Steam quality

*

• Total mass flow

*

• Energy flow

*

• Heat flow

difference

*

• Reynolds number

*

• Density

*

• Pressure

*

• Specific volume

*

• Degrees of

superheat

*

Volume flow

PV filter time – Specify the time to suppress

signal peaks. During the

specified time the analog input

does not respond to an erratic

increase in the process

variable.

Positive floating-

point number

0

Fail safe type – Select the failure mode. • Fail safe value

• Fallback value

• Off

Off

Fail safe value In Fail safe type parameter,

the Fail safe value option is

selected.

Specify the values to be output

when an error occurs.

Signed floating-point

number

0

* Visibility depends on order options or device settings

Loading...

Loading...