EPSON Stylus COLOR 440, 640, and 740 Chapter 2 Operating Principles

44

Head Cleaning Operations

The printer performs a variet

of tasks to keep the printhead clean and

to keep ink from dr

in

out on the printhead’s surface. These tasks

include:

Rubbing and Wiping

Rubbin

and wipin

are performed prior to suctionin

to eliminate dust

and dirt on the printhead. This helps maintain normal ink e

ection and

ensures that a firm seal can be obtained when the printhead is capped

durin

suctionin

.

Rubbin

and wipin

occur when the printhead passes over the cleanin

blade, which can be extended into the path of the printhead or

withdrawn out of its wa

. To learn how this works, see “Pump

Mechanism” on pa

e45.

The cleanin

blade is composed of two materials: felt on the left side

and rubber on the ri

ht. When the carria

e moves ri

ht to left, the

printhead

rubs

a

ainst the rubber half of the blade. When the carria

e

moves left to ri

ht, the printhead

wipes

a

ainst the felt half. A small

amount of ink is sent to the nozzle surface before wipin

to make

adherin

ob

ects come off easil

.

Discharging

Dischar

in

is the electronicall

controlled e

ection of ink from the

printhead. Unlike suctionin

, which uses an external pump, dischar

in

uses the printhead’s own PZTs to perform the operation. Dischar

in

eliminates the viscous ink that forms when ink near the printhead

nozzles starts dr

in

out.

Suctioning

Suctionin

takes place when the printer uses the ink pump to suction

ink awa

from the nozzles. This eliminates trapped air bubbles and

prevents ink from remainin

near the nozzles and dr

in

out.

The printer performs suctionin

at three different power levels. Durin

hi

h-power suctionin

, the printhead is full

capped and the bleed valve

remains closed. This

ives rise to maximum suction. The printer then

switches to medium-power suctionin

, a sensitive operation performed

with the bleed valve open. This eliminates air bubbles formed in the

printhead cavit

durin

hi

h-power suctionin

. Finall

, with the bleed

valve still open but the pump motor runnin

at a lower speed, the printer

performs low-power suctionin

. This vacuums awa

an

ink that

remains on the nozzle plate and in the ink cap followin

other cleanin

procedures.

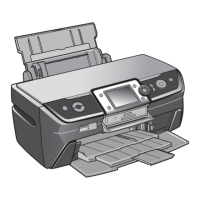

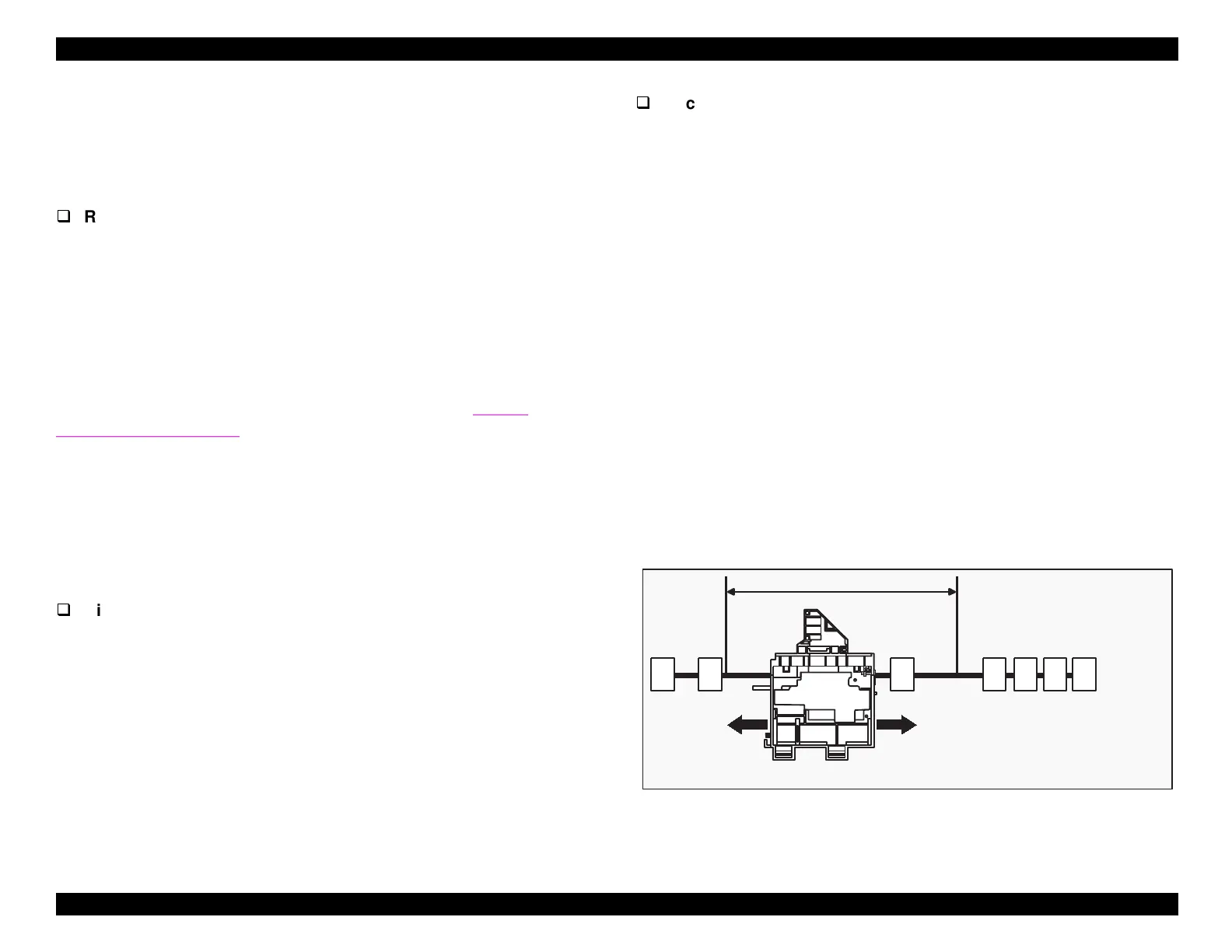

The fi

ure below shows where the carria

e is positioned durin

the

various head cleanin

operations.

Figure 2-11. Carriage Positioning

ABCDE

FG

Printable Area

A: Medium- and low-power suctioning position

B: High-power suctioning position (home position)

C: Discharging position (right)

D: Wiping/rubbing position

E: Cartridge replacement position

F: Discharging position (left)

G: ASF drive position

Loading...

Loading...