Chapter 6 Fastening Operation

PAGE 6-43

System Parameters (controller Information 1)

D-No.000 Torque Unit

All fastening parameters within the Controller will have the same torque unit.

D-No. 001 Software Version Cannot be changed.

This is the software version of the controller.

D-No. 002 Amplifier Version Cannot be changed.

This is the amplifier version.

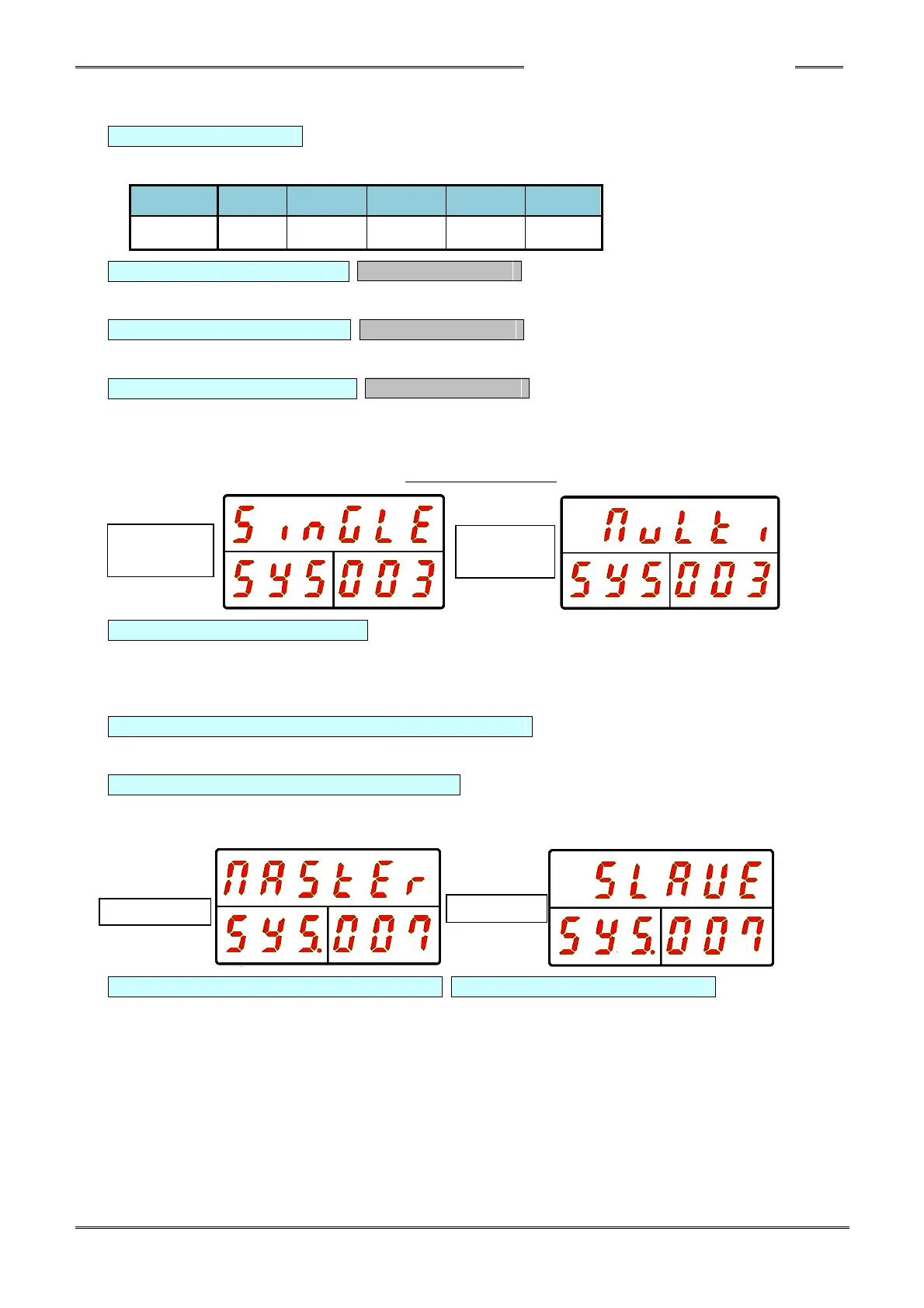

D-No. 003 System Indication Cannot be changed.

Indicates whether the controller is a multi system or a single system configuration.

This is also used to change between the multi system and the single system.

The handheld tool operates only in the single system setting.

D-No. 004 External Gear Ratio Setting range: 0.300 ~ 3.000, standard setting: 1.000

Used to adjust the gear ratio when an external head (that has a gear ratio other than 1:1) is connected

to the output shaft of the tool. Do not use a value other than the standard setting (1.000) unless an

external offset gear is attached.

D-No.005 / 006 For adjustment by the manufacturer

Not used.

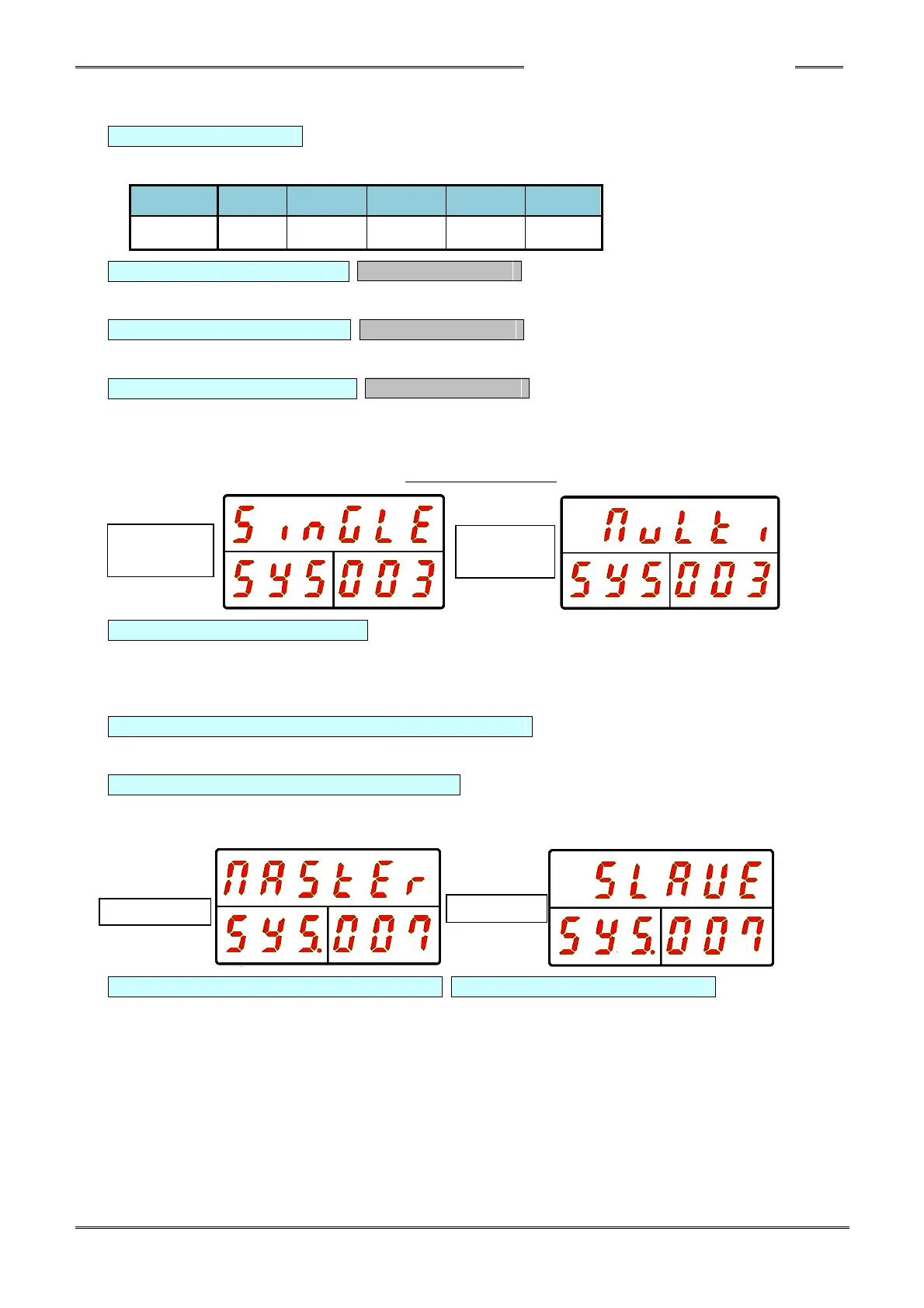

D-No. 007 Communication Axis Indication

This indicates whether the controller is the MASTER spindle for (PC) communication

and I/O (PLC) communication or is a SLAVE Spindle

D-No. 008 Axis Cycle Count (×1 million) D-No. 009 Axis Cycle Count (×1)

Indicates the number of fastening cycles the controller has performed.

* When the count is less than 1 million, [------] is indicated for D-No. 008.

Loading...

Loading...