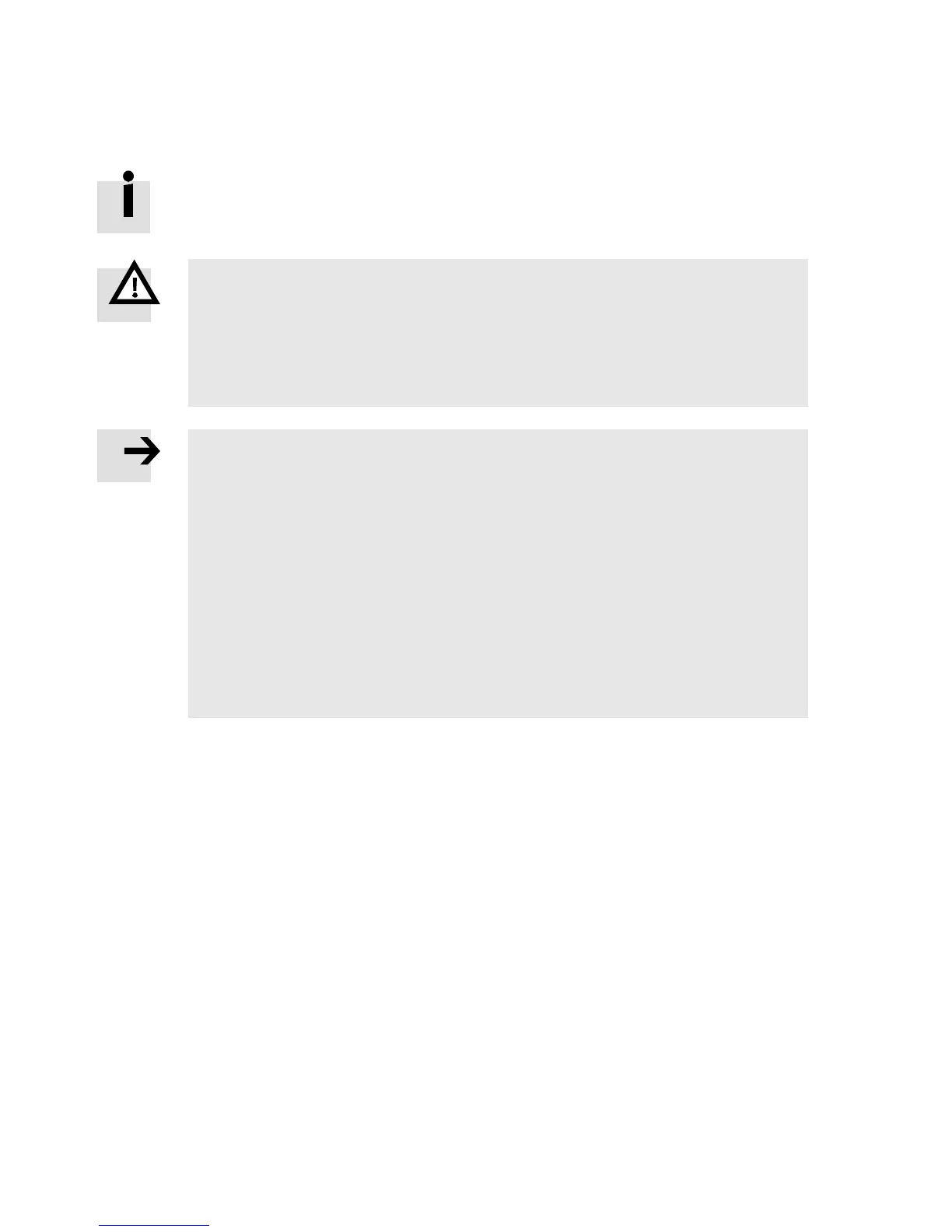

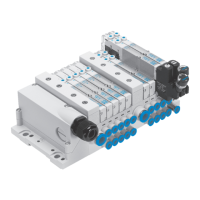

5 Conversion and maintenance

100 Festo – P.BE-MPA-EN – 1309f – English

5.1 General instructions

Information on the delivery status of your valve terminal can be found using the product

key ( section A.1.5).

Warning

Uncontrolled movements of the c onnected actuator technology and loose tubing c an

cause injury to pe rsons and/or damage to property.

• Before carrying out installation and maintenance work, switch off the following:

– Compressed air supply

– Operating and load voltage supply.

Note

• Handle all modules and components of the MPA-S valve terminal with care.

• Note especially the following when mounting components:

– Position screws exactly before tightening (otherwise their threads may be dam-

aged).

– Scre ws should only be tightened by hand. Sc rews must be placed so that the

self-cutting threads can be used.

– The specified torques must be observed.

– Threaded fittings must be free of distortion and mechanical tension.

– Check the seals for damage ( IP 65).

– The contact surfaces must be dry and clean (sealing effect, avoidance of leakage

and contact erro rs).

Loading...

Loading...